Preparation method of refractory high-entropy alloy powder

A high-entropy alloy and powder preparation technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of many impurities, low milling efficiency, difficult preparation, etc., and achieve simple process steps, high milling efficiency, and production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of spherical powder of embodiment 1 refractory high-entropy alloy WTaMoNbZr

[0038] The powder preparation method of the refractory high-entropy alloy WTaMoNbZr described in this embodiment is as follows:

[0039] Step 1: Select five refractory metal elements of W, Ta, Mo, Nb, and Zr as components, and the molar ratio of each component is the same. Weigh 285g of block-shaped W block, 281g of Ta block, 149g of Mo block, 145g of Nb block, and 141g of Zr block with a purity of 99.9%, and put them into the induction coil of the vacuum suspension melting furnace.

[0040] Step 2: Vacuum the vacuum chamber to 2×10 -2Pa, adjust the smelting input power to 360KW, input frequency to 18KHz, repeatedly smelt WTaMoNbZr refractory high-entropy alloy 10 times, each time the smelted alloy stays in the liquid state for 15 minutes, and obtain a refractory high-entropy alloy ingot after cooling, the ingot size is 45mm× 45mm×41mm.

[0041] Step 3: put the cast ingot into a...

Embodiment 2

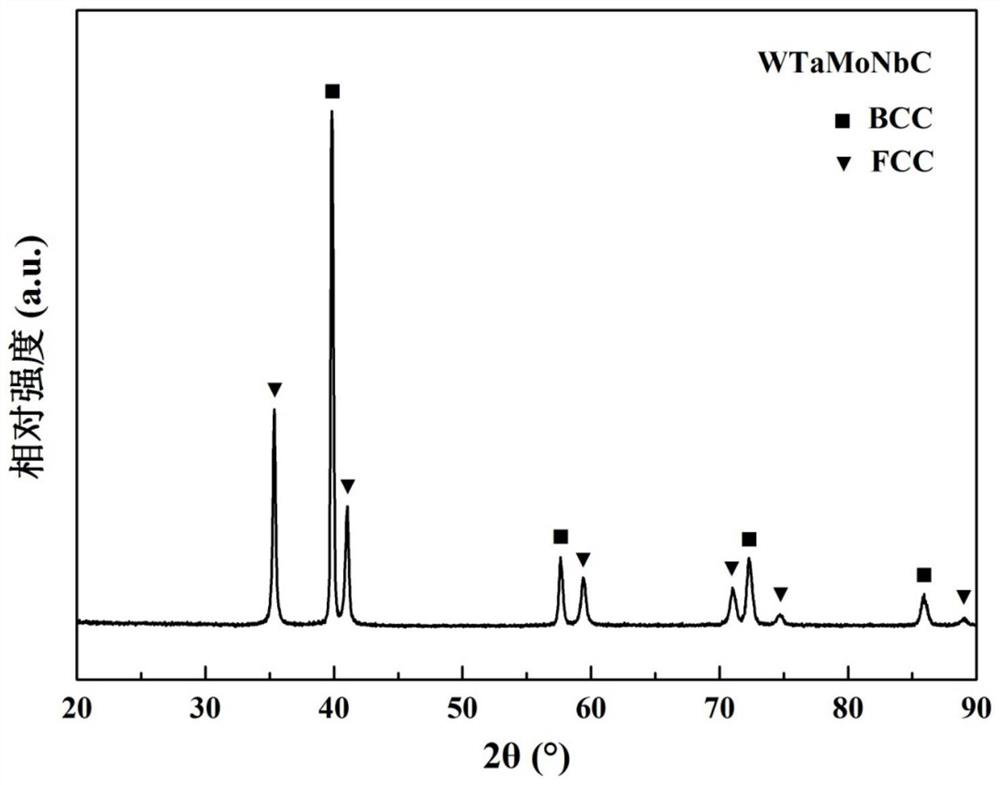

[0045] Preparation of spherical powder of embodiment 2 refractory high-entropy alloy WTaMoNbC

[0046] The powder preparation method of the refractory high-entropy alloy WTaMoNbC described in this embodiment is as follows:

[0047] Step 1: Select W, Ta, Mo, Nb, and C as components, and the molar ratio of each component is the same. 17.3 g of WC block, 16 g of Ta block, 8.5 g of Mo block, and 8.2 g of Nb block with a purity of 99.9% were weighed and put into a water-cooled copper crucible of a vacuum arc melting furnace.

[0048] Step 2: Vacuum the vacuum chamber to 5×10 -3 Pa, then filled with 99.999% high-purity argon until the pressure of the vacuum chamber is 4×10 4 Pa, the melting current is 420A, and the WTaMoNbC refractory high-entropy alloy is repeatedly smelted 5 times. The total time of the alloy in the liquid state is 30 minutes. After cooling, a refractory high-entropy alloy ingot is obtained. The diameter of the ingot is about 26mm and the thickness is about 8mm....

Embodiment 3

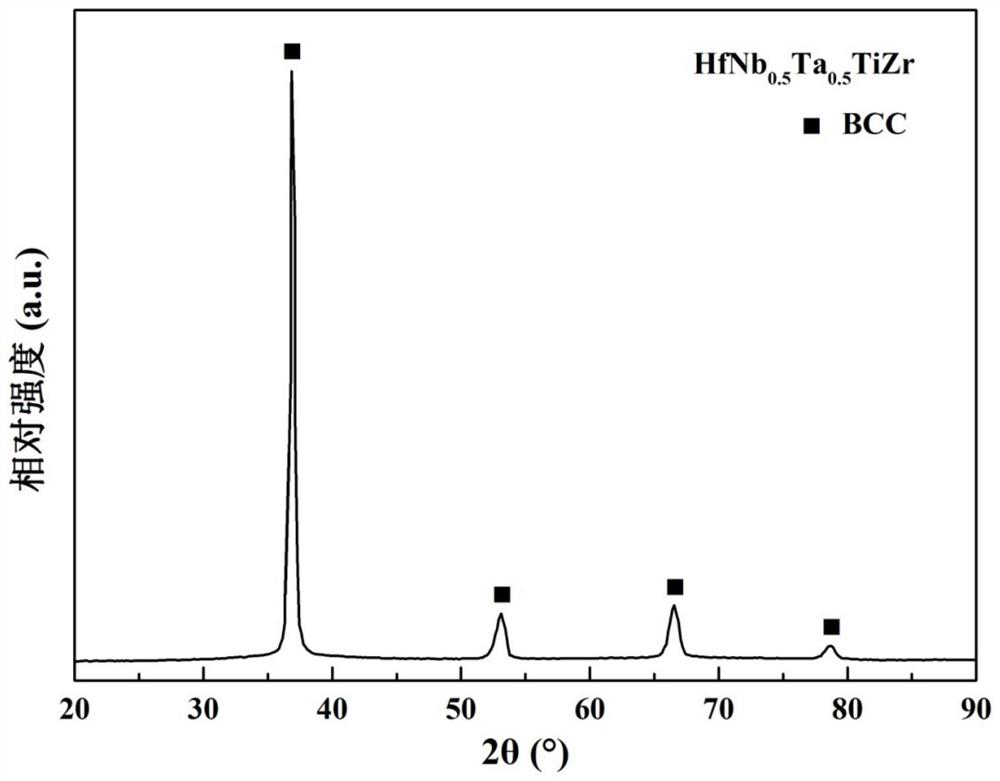

[0052] Embodiment 3 refractory high entropy alloy HfNb 0.5 Ta 0.5 Preparation of spherical powder of TiZr

[0053] The refractory high-entropy alloy HfNb described in this embodiment 0.5 Ta 0.5 The powder preparation method of TiZr is as follows:

[0054] Step 1: Select five metal elements, Hf, Nb, Ta, Ti, and Zr, as components, and prepare an alloy according to the molar percentage of the alloy element content Hf:Nb:Ta:Ti:Zr=25:12.5:12.5:25:25. Weigh 19.64g of Hf particles, 5.11g of Nb particles, 9.95g of Ta particles, 5.27g of Ti particles, and 10.03g of Zr particles with a purity of 99.9%, and put them into a water-cooled copper crucible of a vacuum arc melting furnace.

[0055] Step 2: Vacuum the vacuum chamber to 5×10 -3 Pa, then filled with 99.999% high-purity argon until the pressure of the vacuum chamber is 4×10 4 Pa, smelting current is 400A, repeatedly smelting HfNb 0.5 Ta 0.5 TiZr refractory high-entropy alloy was processed 5 times, and the alloy was in liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com