High-strength polylactic acid functional composite material with antibacterial and electromagnetic shielding properties and preparation method thereof

A functional composite material, electromagnetic shielding technology, applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve the problems of poor dispersion, weak interfacial interaction force, complex structure, limited improvement of polylactic acid mechanical properties, etc., to achieve excellent antibacterial properties. Effect and electromagnetic shielding function, reduce pollution, good effect of mechanical enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A high-strength polylactic acid functional composite material with antibacterial and electromagnetic shielding properties, the preparation method of which comprises the following steps:

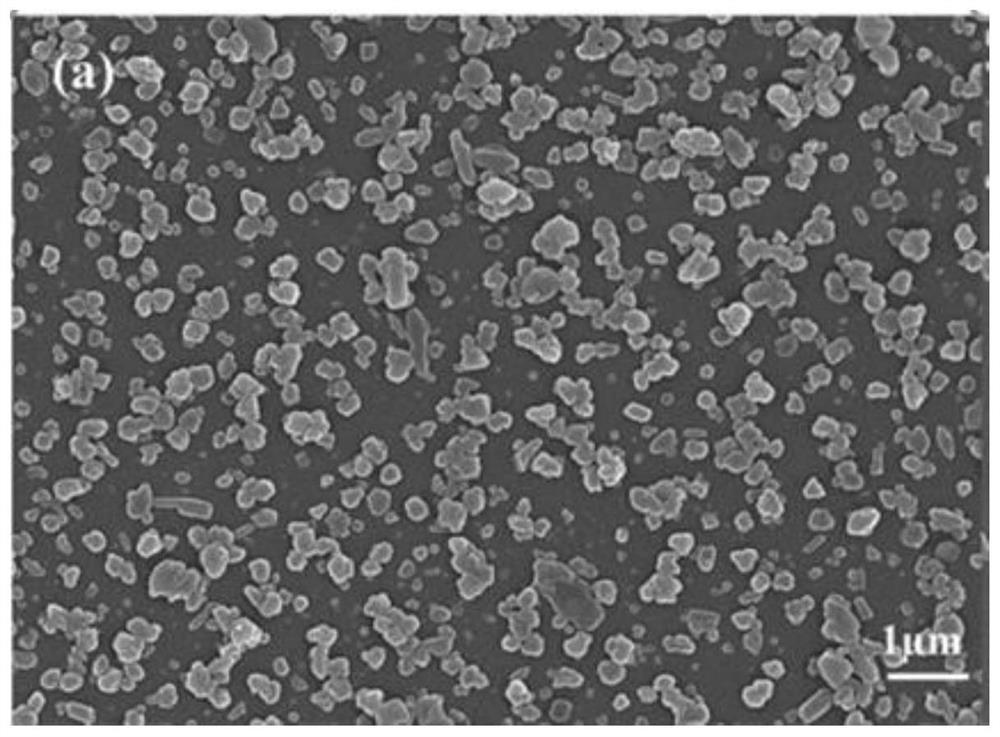

[0036] (1) Controllable preparation of nano-lignin

[0037] Measure 20ml of deionized water into the ball mill jar, add 3g of native lignin, and use ultrasonic dispersion for 30min to obtain a uniformly dispersed composite solution. Finally, put the ball mill into the ball mill and continue to react at 480rpm for 72 hours, filter and wash with a Buchner funnel to obtain filter residue, and freeze-dry for 48 hours with a freeze dryer to obtain nano-lignin.

[0038] (2) Preparation of zinc oxide / silver composite

[0039] 1g of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 12 mL of deionized water, then 6 mL of triethanolamine (TEA) was added to the solution, and stirred at room temperature to completely dissolve; at the same time, 5.4 mg of FeCl3·6H2O was added to 200 mL of ethylene glycol ( E...

Embodiment 2

[0043] A high-strength polylactic acid functional composite material with antibacterial and electromagnetic shielding properties, the preparation method of which comprises the following steps:

[0044] (1) Controllable preparation of nano-lignin

[0045] Carry out the controllable preparation of nano-lignin according to example 1

[0046] (2) Preparation of zinc oxide / silver composite

[0047] Zinc oxide / silver composite preparation was carried out according to Example 1.

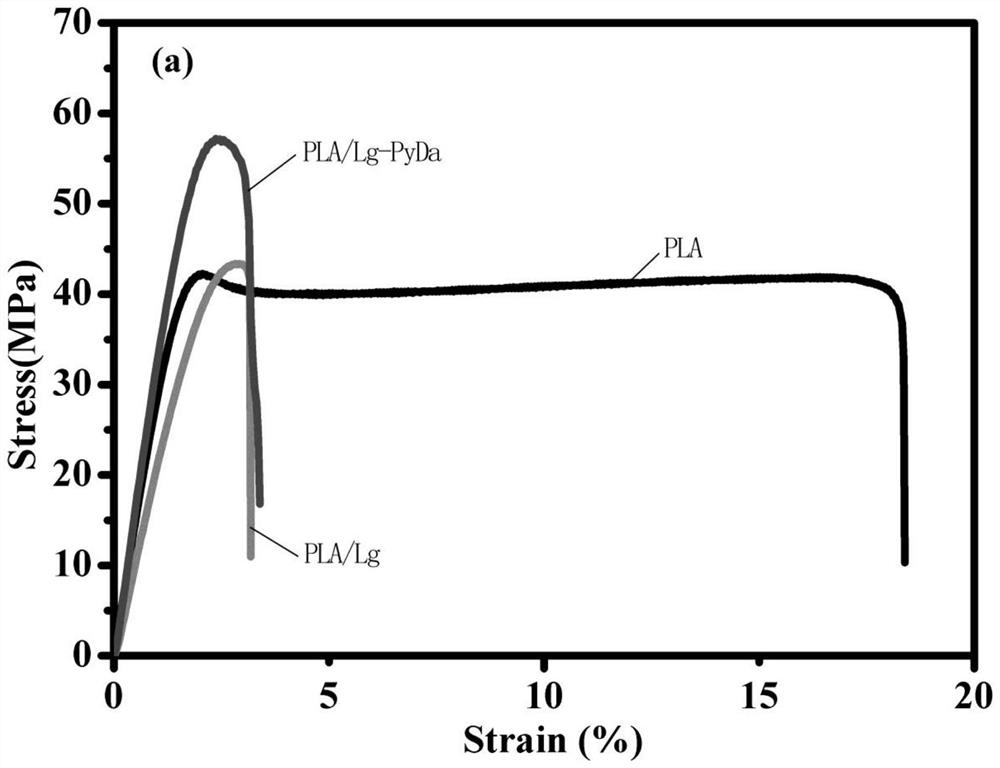

[0048] (3) Preparation of multifunctional polylactic acid composite materials

[0049] Dissolve 1.5g PLA particles in 20mL of dichloromethane (PLA concentration 75-100mg / mL) at room temperature and stir for 8h to completely dissolve, add (2-6wt%) nano lignin and continue stirring for 12h, add 10wt % of the zinc oxide / silver complex was ultrasonicated for 1 hour, stirred for 12 hours, solvent-spectrum filmed, and volatilized in a fume hood for 2 days to form a film to obtain a polylactic acid functional f...

Embodiment 3

[0051] A high-strength polylactic acid functional composite material with antibacterial and electromagnetic shielding properties, the preparation method of which comprises the following steps:

[0052] (1) Controllable preparation of nano-lignin

[0053] Carry out the controllable preparation of nano-lignin according to example 1

[0054] (2) Preparation of zinc oxide / silver composite

[0055] Carry out zinc oxide / silver composite preparation according to example 1

[0056] (3) Preparation of multifunctional polylactic acid composite materials

[0057] Dissolve 1.5g PLA particles in 20mL of dichloromethane (PLA concentration 75-100mg / mL) at room temperature and stir for 8h to completely dissolve, add (2-6wt%) nano lignin and continue stirring for 12h, add 15wt % of the zinc oxide / silver complex, ultrasonicated for 1 hour, stirred for 12 hours, then solvent-coated, and volatilized in a fume hood for 2 days to form a film to obtain a polylactic acid functional film material. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com