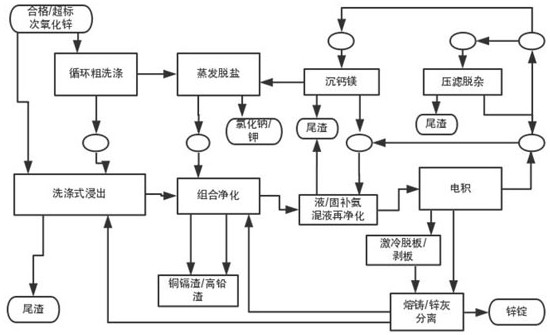

Combined long-term stable operation ammonium chloride method zinc electrolysis process flow

A technology with a process flow and stable operation, applied in the electrolysis process, photography process, electrolysis components, etc., can solve the problems of incomplete system, unsuitable equipment, large consumption of zinc powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Example 1. Direct leaching of raw materials

[0023] The raw material is secondary zinc oxide, containing 41% zinc, 4% lead, and 4% fluorine and chlorine. The raw material is sent to the leaching tank after a screw feeder or pulping at a speed of 4.5 tons / hour, and is subjected to countercurrent washing and leaching. The leaching liquid-solid ratio is 8-12:1, the leaching liquid contains ammonium chloride 4.5-5.5mol / l, the temperature is 30-90 degrees, stirred, the leaching time is 2 hours, the leaching liquid contains more than 37g / l of zinc, 3.6g / l of lead, and others Copper 0.05g / l, cadmium 0.3g / l, iron trace;

example 2

[0024] Example 2, leaching after rough washing of ultra-impurity raw materials

[0025] Small ash: 61% zinc, 5% iron, 15.5% fluorine and chlorine, sent to coarse cycle washing and pressure filtration, 62.2% zinc, 5.4% iron, less than 6% fluorine and chlorine, sent to leaching;

example 3

[0026] Example 3. Combined purification of leaching solution

[0027] Leaching solution: zinc 37g / l, lead 5g / l, trace iron, other copper 0.05, cadmium 0.3, two-stage coarse purification of zinc scum, one-stage deep purification of zinc powder, one-stage mixed liquid supplementation of ammonia and then purified liquid, Zinc 38g / l, lead 0.008, copper 0.003, cadmium 0.006, other trace amounts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com