Construction method for partition pouring of special-shaped integral bearing platform through non-dismantling formwork alternative bay method

A technology without dismantling formwork and construction method, which is applied in construction, infrastructure engineering and other directions, can solve the problems of unguaranteed construction quality and affect the safety of bridges, and achieve the effect of improving construction efficiency, saving construction costs and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

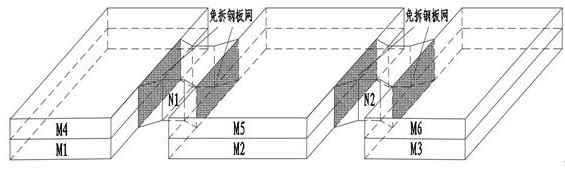

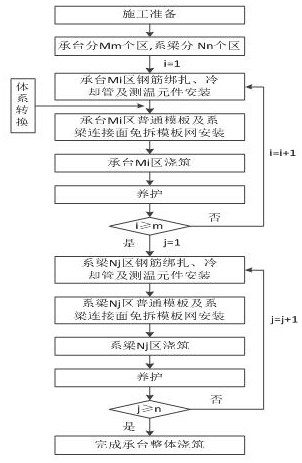

[0085] see Figure 1-6 , the present invention provides a technical solution: a construction method of dismantling-free formwork jump warehouse method for sub-area casting of special-shaped integral caps, which is characterized in that it includes the following aspects:

[0086] 1. Process principle

[0087] mainly includes:

[0088] (1) Construction by jumping warehouse method: In this construction method, the entire cap is divided into different areas before construction, and the cap area is constructed first, and then the connecting tie beams are constructed. This method turns two construction joints into one construction joint, and the adjacent concrete pouring joints are tight and integrated, canceling the secondary pouring, shortening the construction time, and improving the construction efficiency; at the same time, the internal stress of the early concrete can be released as much as possible, Relieve and reduce the restraint effect, and use the tensile capacity of co...

Embodiment 2

[0157] Yafu Road (Chaohu South Road ~ Ganggang Avenue) project in Chaohu City

[0158] 1. Project overview

[0159] The Yafu Road (Chaohu South Road-Ganggang Avenue) project in Chaohu City is located in the southeast area of Chaohu City. The starting point of the project is Chaohu South Road (stake number: 0+54.921), and the end point is Ganggang Avenue (stake number: 26+30). Going east-west, it intersects with Chaohu South Road, Wangzhi Road, Wangye Road, Shugang Avenue, and Ganggang Avenue along the way (the Ganggang Avenue is the current road, Chaohu South Road is the road under construction, and the rest are planned roads), with a total length of about 2.585 kilometers , the standard section width of the road is 52m, and it is an urban trunk road.

[0160] Yafu Road Crossing Yuxi River Bridge is a super-large bridge with a total length of 974m. There are five bridges in total, the fourth bridge is the main bridge and crosses the Yuxi River, and the second bridge spans Sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com