PVDC high-barrier co-extrusion self-adhesive film for military protection and preparation method thereof

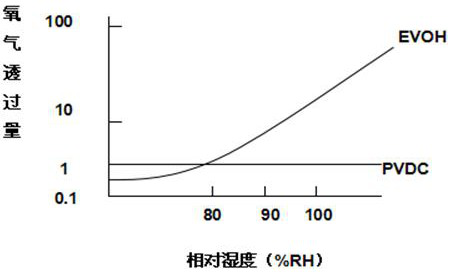

A high-barrier, self-adhesive film technology, applied in the direction of protective equipment, protective clothing, chemical instruments and methods, etc., can solve the problems of antistatic agent failure, antistatic effect instability, breakdown, etc., to improve flame retardancy and antistatic Electrostatic properties, improved electromagnetic shielding effect, and excellent moisture-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

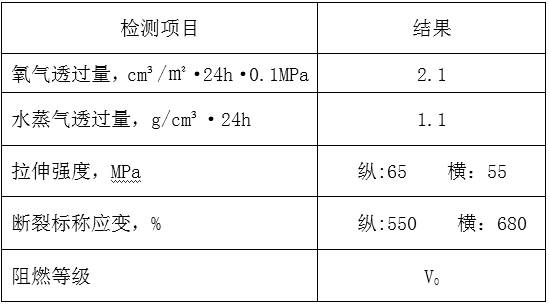

[0023] A PVDC high-barrier co-extruded self-adhesive film for military protection, consisting of an outer layer, a first adhesive layer, a PVDC layer, a second adhesive layer, a sub-inner layer and an inner layer arranged in sequence, and the outer layer includes 70% Linear low-density polyethylene, 30% low-density polyethylene, modified graphene is linear low-density polyethylene, 5% of the total mass of low-density polyethylene, and the quality of plasticizer is linear low-density polyethylene, low-density polyethylene 1% of the total mass, and the mass of the flame retardant masterbatch is 30% of the total mass of linear low density polyethylene and low density polyethylene. The second inner layer includes 70% linear low-density polyethylene, 20% low-density polyethylene, and 10% metallocene polyethylene, and the mass of plasticizer is 1% of the total mass of linear low-density polyethylene, low-density polyethylene, and metallocene polyethylene. %, the mass of boron nitrid...

Embodiment 2

[0039] A PVDC high-barrier co-extruded self-adhesive film for military protection, consisting of an outer layer, a first adhesive layer, a PVDC layer, a second adhesive layer, a sub-inner layer and an inner layer arranged in sequence,

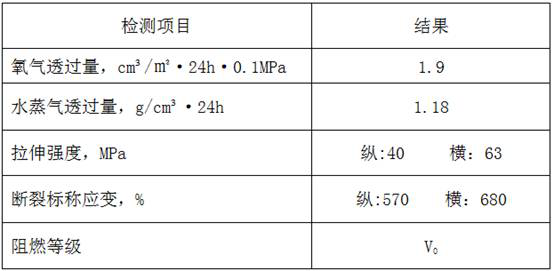

[0040] The outer layer is made of 75% linear low density polyethylene, 25% low density polyethylene, 7% modified graphene, 20% flame retardant masterbatch, 1% plasticizer, 1.5% boron nitride, 4% diatomaceous earth, Composition of 4% hydrophobic silica. The sub-inner layer is composed of 55% linear low density polyethylene, 22% low density polyethylene, 23% metallocene polyethylene, 1.5% antistatic masterbatch, 2.0% boron nitride, 22% flame retardant masterbatch and 1% plasticizer agent composition. The inner layer is composed of 50% linear low density polyethylene, 25% low density polyethylene, 25% metallocene polyethylene, 1.5% opening slip agent, 3% boron nitride, 2% aluminum oxide, 18% antistatic masterbatch and 1% plasticizer composition....

Embodiment 3

[0046] A PVDC high-barrier co-extrusion self-adhesive film used for military protection consists of an outer layer, a first adhesive layer, a PVDC layer, a second adhesive layer, a secondary inner layer and an inner layer arranged in sequence. The outer layer includes 73% linear low-density polyethylene, 22% low-density polyethylene, the flame-retardant masterbatch is 17% of the total mass of linear low-density polyethylene, low-density polyethylene, and modified graphene, and the antistatic masterbatch is linear 13% of the total mass of low-density polyethylene, low-density polyethylene, and modified graphene, and the plasticizer is 1% of the total mass of linear low-density polyethylene, low-density polyethylene, and modified graphene, and the modified graphene is 7% of the total mass of linear low-density polyethylene, low-density polyethylene, and modified graphene. The sub-inner layer is composed of 52% linear low density polyethylene, 24% low density polyethylene, 24% me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com