A kind of high workability cement dispersion polymer and preparation method thereof

A polymer and cement technology, used in solid waste management, climate sustainability, sustainable waste treatment, etc., can solve problems such as poor workability of water reducing agents, achieve high water reduction rate, improve cohesion and water retention , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

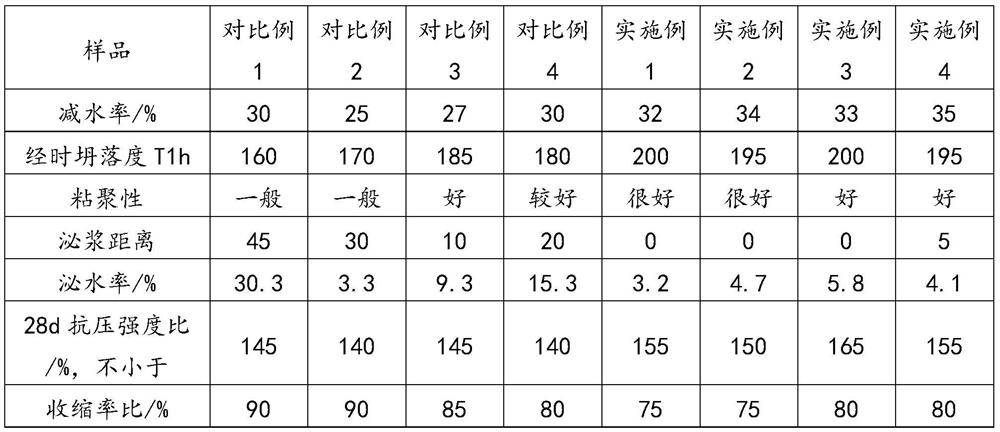

Examples

preparation example Construction

[0041] The invention provides a preparation method of high workability cement dispersion polymer, which specifically comprises the following steps:

[0042]The ester group-containing polymer and polyethylene glycol monomethyl ether were added to the reactor, the temperature was raised to 95°C, and nitrogen was continuously introduced. After all the water was distilled, carboxymethyl starch and a catalyst were added, and the reaction temperature was raised to 120 ~ 160 ℃, while vacuuming to make it react for 2 ~ 4 hours under the vacuum degree of 40 ~ 80 mbar, the polymer in the molten state can be sliced, or cooled to below 70 ℃, add a certain amount of water and mass concentration It is neutralized with 30% sodium hydroxide, so that pH=6~7, that is, a cement dispersing polymer with a mass concentration of 50% is prepared, and the molecular weight is 60000~100000.

[0043] Wherein, the preparation method of the described ester group-containing polymer comprises the following s...

Embodiment 1

[0049] 1) the deionized water of 50g is joined in the reactor, when temperature rises to 30 ℃, drip 25g mass concentration respectively and be 10% hydrogen peroxide solution A, 35g mass concentration is 5% L-ascorbic acid aqueous solution B, 10min After that, the mixed solution C of 35g methyl acrylate, 40g 4-vinyl benzoic acid, 25g sodium methallyl sulfonate and 30g deionized water was added dropwise and dripped in 100min,

[0050] 2) After the dropwise addition, add 5g of solution A and finish dropping within 10min, and ripen for 0.5 hour to obtain a copolymer solution with a solid content of 45.5%, a viscosity of 660cps and a weight average molecular weight of 6700.

[0051] 3) 200g of copolymer and 50g of polyethylene glycol monomethyl ether were added to the reactor, the temperature was raised to 95°C, and nitrogen was continued to be introduced. After all the water was distilled, 20g of carboxymethyl starch and 1g of rare earth solid superacid SO were added. 4 2- / TiO ...

Embodiment 2

[0053] 1) the deionized water of 50g is joined in the reactor, when temperature rises to 30 ℃, drip 25g mass concentration respectively and be 10% ammonium persulfate aqueous solution A, 35g mass concentration is 5% sodium hypophosphite aqueous solution B , after 10min, add dropwise the mixed solution C of 40g of ethyl acrylate, 45g of 4-vinylphenylacetic acid, 15g of sodium styrene sulfonate and 30g of deionized water and drip it in 100min,

[0054] 2) After the dropwise addition, add 5g of solution A with a mass concentration of 10% and drip it in 10min, and ripen for 0.5 hour to obtain a copolymer solution with a solid content of 45.7%, a viscosity of 760cps and a weight-average molecular weight of 7800. .

[0055] 3) 200g of copolymer and 60g of polyethylene glycol monomethyl ether were added to the reactor, the temperature was raised to 95° C., and nitrogen was continued to be introduced. After all the water was distilled, 10g of carboxymethyl starch and 1g of rare earth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com