MgFe hydrotalcite-based catalyst and application thereof in production of biodiesel by hydrodeoxygenation in suspended bed

A biodiesel, talc-based technology, used in catalyst activation/preparation, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low freezing point and high cetane number of biodiesel , complex production process and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

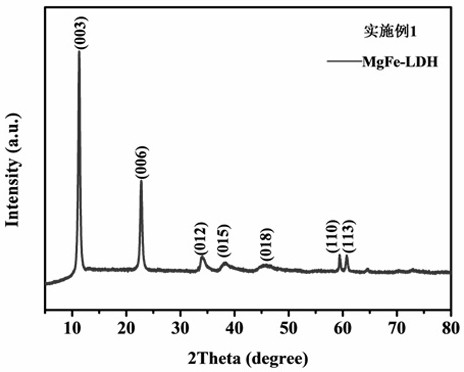

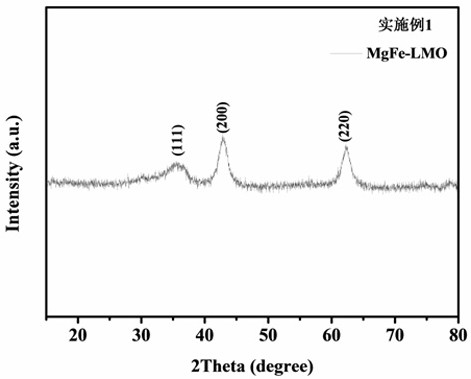

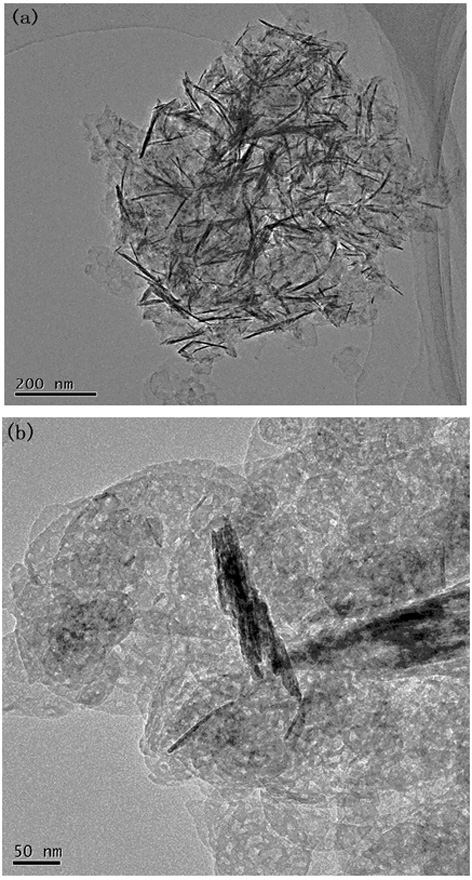

Embodiment 1

[0032] 0.03 mol MgCl 2 •6H 2 O and 0.01 mol FeCl 3 •6H 2 O was dissolved in 100 ml deionized water to form a 0.4mol / L A solution, and 0.08 mol NaOH, 0.005 mol NaOH 2 CO 3 Add to 80 ml of deionized water to obtain a 1.0mol / L clear B solution, under the condition of vigorous stirring (800 rpm), slowly add the obtained B solution to the A solution drop by drop to form a uniform suspension, and then Stir vigorously at room temperature for 1 h, then transfer the aged suspension to a stainless steel reactor with a polytetrafluoroethylene liner, statically crystallize at 140 °C for 12 h, take it out and cool to room temperature, the obtained The precipitate was filtered and washed, and then dried in an oven at 120 °C to constant weight to obtain the precursor of binary magnesium-iron hydrotalcite, and finally the obtained binary magnesium-iron hydrotalcite precursor was placed in a muffle furnace and calcined at 500 °C for 6 h to obtain a layered porous magnesium-iron hydrotalci...

Embodiment 2

[0035] 0.027 mol MgCl 2 •6H 2 O and 0.013 mol FeCl 3 •6H 2 O was dissolved in 100 ml deionized water to form a 0.4mol / L A solution, and 0.08 mol NaOH, 0.0067 mol Na 2 CO 3 Add to 80 ml of deionized water to obtain a 1.0mol / L clear B solution, under the condition of vigorous stirring (800 rpm), slowly add the obtained B solution to the A solution drop by drop to form a uniform suspension, and then Stir vigorously at room temperature for 1 h, then transfer the aged suspension to a stainless steel reactor with a polytetrafluoroethylene liner, statically crystallize at 140 °C for 12 h, take it out and cool to room temperature, The resulting precipitate was filtered and washed, and dried in an oven at 120 °C to constant weight to obtain a binary magnesium-iron hydrotalcite precursor. Finally, the obtained binary magnesium-iron hydrotalcite precursor was placed in a muffle furnace and calcined at 500 °C After 6 h, the layered porous magnesium-iron hydrotalcite-based catalyst wa...

Embodiment 3

[0038] 0.02 mol MgCl 2 •6H 2 O and 0.02 mol FeCl 3 •6H 2 O was dissolved in 100 ml deionized water to form a 0.4mol / L A solution, and 0.08 mol NaOH, 0.01 mol NaOH 2 CO 3 Add to 80 ml of deionized water to obtain a 1.0mol / L clear B solution, under the condition of vigorous stirring (800 rpm), slowly add the obtained B solution to the A solution drop by drop to form a uniform suspension, and then Stir vigorously at room temperature for 1 h, then transfer the aged suspension to a stainless steel reactor with a polytetrafluoroethylene liner, statically crystallize at 140 °C for 12 h, take it out and cool to room temperature, the obtained The precipitate was filtered and washed, and then dried in an oven at 120 °C to constant weight to obtain the precursor of binary magnesium-iron hydrotalcite, and finally the obtained binary magnesium-iron hydrotalcite precursor was placed in a muffle furnace and calcined at 500 °C for 6 h to obtain a layered porous magnesium-iron hydrotalcit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com