Insulating fluororubber material as well as preparation method and application thereof

A technology of fluororubber and raw materials, which is applied in the field of insulating fluororubber materials and its preparation, can solve the problems of fluororubber materials such as increased volume swelling and decreased electrical insulation, and achieve the reduction of volume resistivity, reduction of adsorption capacity, and strengthening of bonding The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

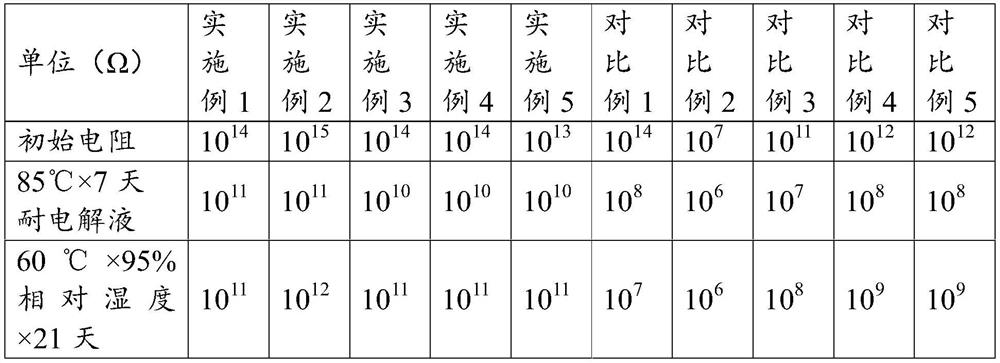

Examples

Embodiment 1

[0037] An embodiment of an insulating fluororubber material and a preparation method of the present invention, the insulating fluororubber material includes the following preparation raw materials in parts by weight:

[0038] 100 parts of fluororubber, 5 parts of talc, 0.3 parts of di-n-butoxy bis(ethyl acetoacetate) titanate, 20 parts of N990 carbon black, 1 part of 2,5-dimethyl-2,5-di (tert-butylperoxy)hexane, 3 parts of triallyl isocyanurate, 2 parts of processing aids;

[0039] The fluororubber model is GF200S; the average particle size of the talcum powder is 1250 mesh, and the acid-soluble iron content is <0.3%.

[0040] The preparation method of the insulating fluororubber material, the specific steps are as follows:

[0041] (1) Dry the talc powder in an oven at 300°C for 1 hour; dissolve di-n-butoxy bis(ethyl acetoacetate) titanate in triallyl isocyanuric acid at a temperature of 30°C to 40°C In the ester liquid, use hydrochloric acid to adjust the pH value to 5.5-7.0...

Embodiment 2

[0045] The raw materials for the preparation of the insulating fluororubber material are the same as those in Example 1, except that the carbon black N990 in Example 1 is reduced to 15 parts, and the talcum powder is increased to 10 parts.

Embodiment 3

[0047] In addition to replacing the di-n-butoxy bis(ethyl acetoacetate) titanate in Example 1 with an equivalent amount of bis-triethanolamine diisopropyl titanate, the raw materials for the preparation of the insulating fluororubber material were Composition and preparation method are completely identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com