Modified full-bio-based PBAT biodegradable plastic and preparation method thereof

A technology for biodegradable plastics and degradable plastics, applied in the field of modified full bio-based PBAT biodegradable plastics and their preparation, can solve the problems of poor flame retardant performance, poor heat resistance, and high cost, and achieve improved mechanical properties, Improved compatibility and improved longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

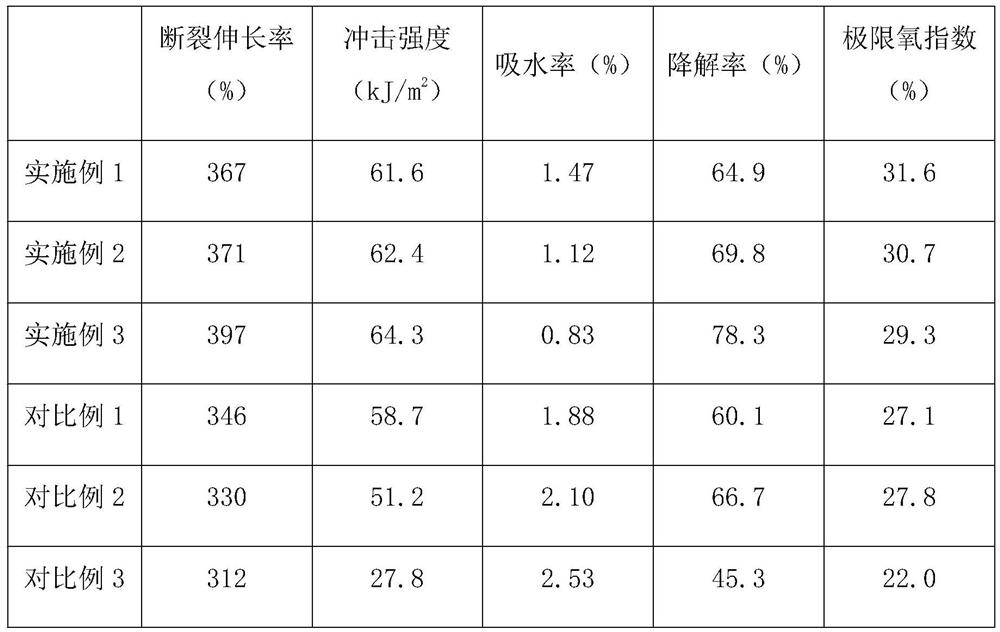

Examples

Embodiment 1

[0040] (1) Preparation of bio-based flame retardant:

[0041] Add phytic acid and itaconic acid to acetone, stir and mix, add ammonium persulfate, react at 60°C for 4 hours, wash and dry to obtain product A; the mass of each component in product A is: 3.0 parts of phytic acid, 1.0 part of itaconic acid Acid, 0.006 parts of ammonium persulfate;

[0042] Take product A, add epichlorohydrin and tetramethylammonium chloride, react at 80°C for 1h, cool down to 30°C, add sodium hydroxide solution, react for 1h, wash and dry to obtain product B; product B is composed of the following weight Separately obtained: 10 parts of product A, 5 parts of product B, 90 parts of epichlorohydrin, 3.0 parts of tetramethylammonium chloride, 8 parts of sodium hydroxide;

[0043]Take feather powder, add urea solution, soak at 50°C for 24 hours, add sodium sulfide solution and sodium lauryl sulfate, stir for 30 minutes, filter, dialyze to obtain protein solution; add glycerin and product B, stir at 7...

Embodiment 2

[0052] (1) Preparation of bio-based flame retardant:

[0053] Take phytic acid and itaconic acid, add acetone, stir and mix, add ammonium persulfate, react at 80°C for 7 hours, wash and dry to obtain product A; the quality of each component in product A is: 3.1 parts of phytic acid, 1.1 parts of itaconic acid Acid, 0.008 parts of ammonium persulfate;

[0054] Take product A, add epichlorohydrin and tetramethylammonium chloride, react at 105°C for 3h, cool down to 45°C, add sodium hydroxide solution, react for 4h, wash and dry to obtain product B; product B is composed of the following weight Separately obtained: 10 parts of product A, 5.5 parts of product B, 95 parts of epichlorohydrin, 3.1 parts of tetramethylammonium chloride, 9 parts of sodium hydroxide;

[0055] Take feather powder, add urea solution, soak at 62°C for 25 hours, add sodium sulfide solution and sodium lauryl sulfate, stir for 45 minutes, filter, dialyze to obtain protein solution; add glycerin and product B...

Embodiment 3

[0064] (1) Preparation of bio-based flame retardant:

[0065] Take phytic acid and itaconic acid, add acetone, stir and mix, add ammonium persulfate, react at 100°C for 10 hours, wash and dry to obtain product A; the quality of each component in product A is: 3.3 parts of phytic acid, 1.3 parts of itaconic acid Acid, 0.010 parts of ammonium persulfate;

[0066] Take product A, add epichlorohydrin and tetramethylammonium chloride, react at 130°C for 5h, cool down to 60°C, add sodium hydroxide solution, react for 7h, wash and dry to obtain product B; product B is composed of the following weight Separately obtained: 10 parts of product A, 6 parts of product B, 100 parts of epichlorohydrin, 3.3 parts of tetramethylammonium chloride, 10 parts of sodium hydroxide;

[0067] Take feather powder, add urea solution, soak at 75°C for 27 hours, add sodium sulfide solution and sodium lauryl sulfate, stir for 60 minutes, filter, dialyze to obtain protein solution; add glycerin and product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com