Preparation and application of SnO2@PPy/carbon cloth composite electrode material

A composite electrode and composite material technology, which is applied in the direction of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, tin oxide, etc., can solve the problems of poor PPy capacitor performance, high energy consumption, and long time, so as to improve capacitor performance, Simplify the operation steps and enhance the effect of binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

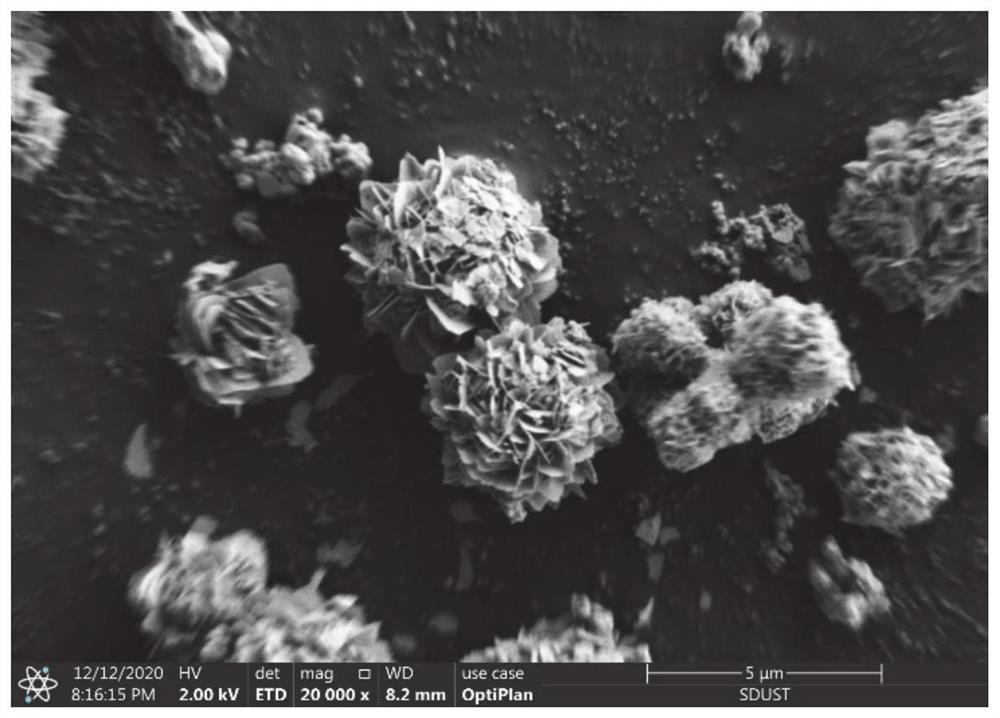

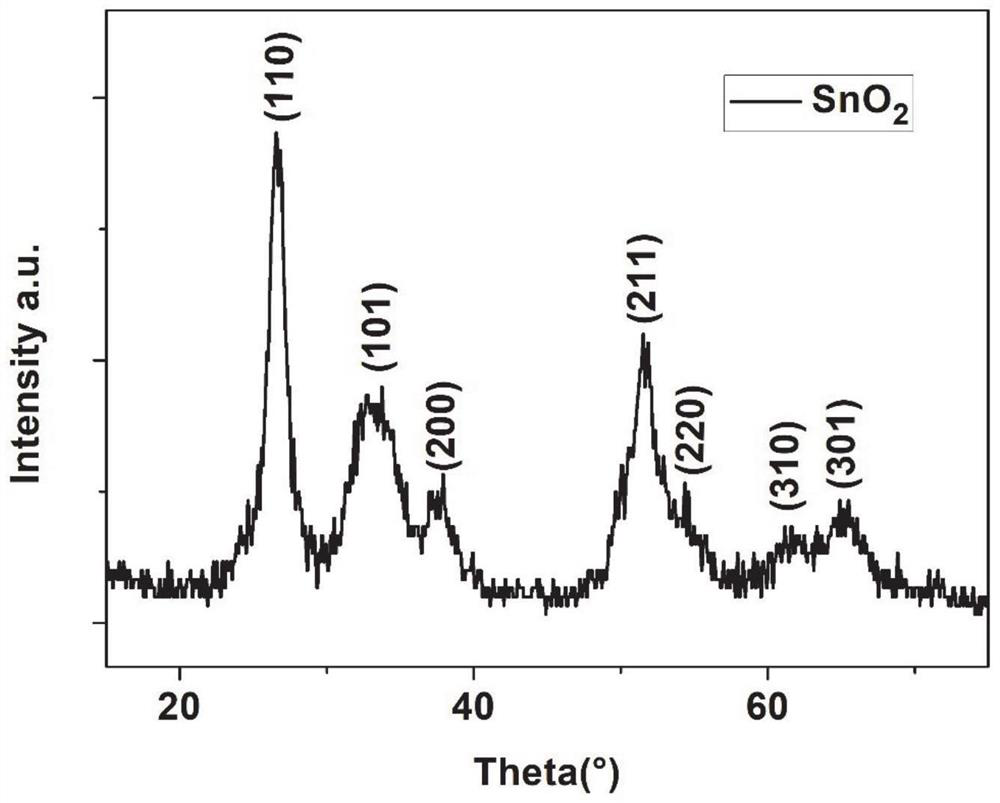

[0028] The first aspect of the present invention provides a three-dimensional flower-like structure of SnO 2 The preparation method of the material includes: mixing the tin salt solution and the alkaline ligand solution, and reacting to obtain a three-dimensional flower-like structure of SnO 2 Material.

[0029] Select basic ligand to react with tin salt, the principle is:

[0030] Sodium citrate plays the role of stabilizer, complexing agent in this step, can form alkaline environment, promote Sn(OH) 4 Precipitation Formation, Sn(OH) 4 Precipitation will remove two molecules of water under appropriate hydrothermal conditions to generate SnO 2 .

[0031] The purpose of using strong base in the prior art is to form an alkaline environment and promote the formation of precipitation, which is similar to sodium citrate, but stronger in alkalinity and difficult to control. Moreover, the prior art often adopts a calcination step, and the purpose of calcination is to make the Sn...

Embodiment 1

[0091] Three-dimensional flower-like structure of SnO 2 material preparation

[0092] 1. Preparation of metal salt solution: accurately weigh 0.564g tin protochloride dihydrate (SnCl 2 2H 2 O) Place in a 100mL small beaker, add 10mL ethanol and 10mL deionized water in turn, stir for 10min to mix evenly, and then sonicate for about 30min until the white crystals are completely dissolved.

[0093] 2. Preparation of precipitant: accurately weigh 1.473g trisodium citrate (C 6 h 5 Na 3 o 7 ), placed in a 100mL small beaker, sequentially added 10mL ethanol and 10mL deionized water, and stirred in a 40°C water bath for 30min until the white crystals at the bottom of the beaker completely disappeared. Trisodium citrate is a strong base and weak acid salt, which will generate hydroxide ions after dissolving in water, forming an alkaline environment. Hydroxide ions are further combined with metal ions to be precipitated.

[0094] 3. SnO 2 Preparation: Nanomaterials were prepare...

Embodiment 2

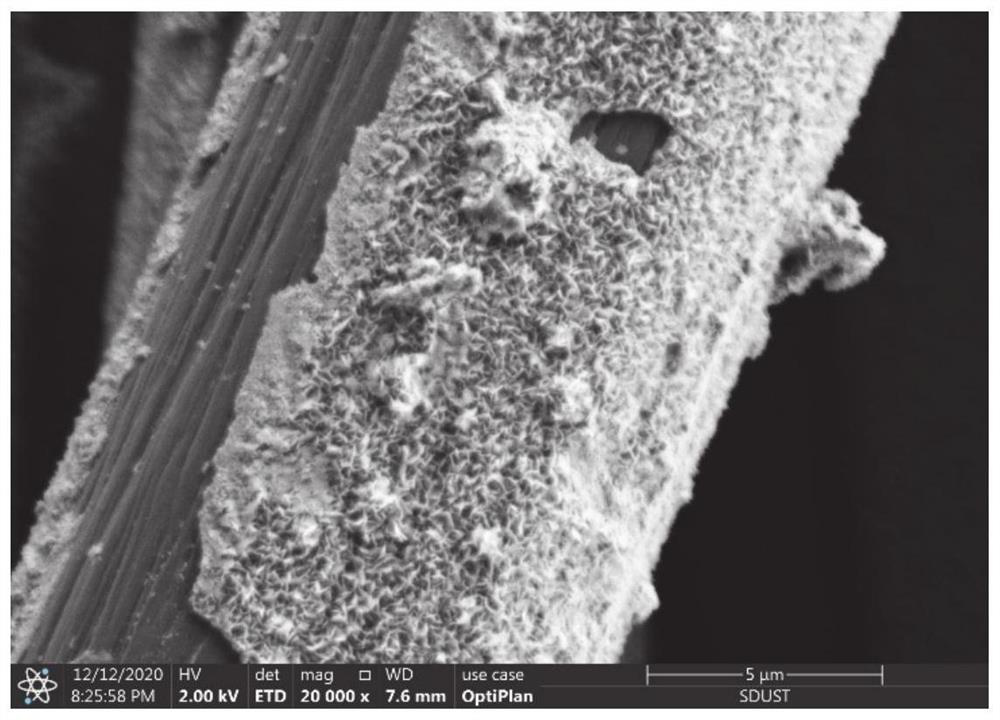

[0096] SnO 2 Preparation of @PPy / carbon cloth composite electrode material

[0097] 1. Pretreatment of carbon cloth: Cut the carbon cloth into small pieces of 1*2cm, rinse with acetone, ethanol and deionized water in sequence. Place the cleaned carbon cloth in an oven at 60°C to dry overnight. Prepare a mixed solution of concentrated hydrochloric acid: concentrated nitric acid = 1:1 (volume ratio), place the carbon cloth in it, soak it for 6 hours, then wash it with distilled water several times until neutral, and finally dry it in an oven at 60°C overnight, collect stand-by.

[0098] 2. Preparation of metal salt solution: use an electronic balance to accurately weigh 0.564g of stannous chloride dihydrate (SnCl 2 2H 2 O) Place in a 100mL small beaker, add 10mL of ethanol and 10mL of deionized water in turn, stir for 10min to mix evenly, and then sonicate for 30min until the white crystals are completely dissolved.

[0099] 3. Preparation of precipitant: accurately weigh 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com