Testing device and automatic testing method thereof

A technology of automatic testing and testing equipment, applied in the direction of electronic circuit testing, etc., can solve problems such as cumbersome operation steps, long operation time, and impact on production capacity, and achieve the effect of convenient switching and debugging, and simplified operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

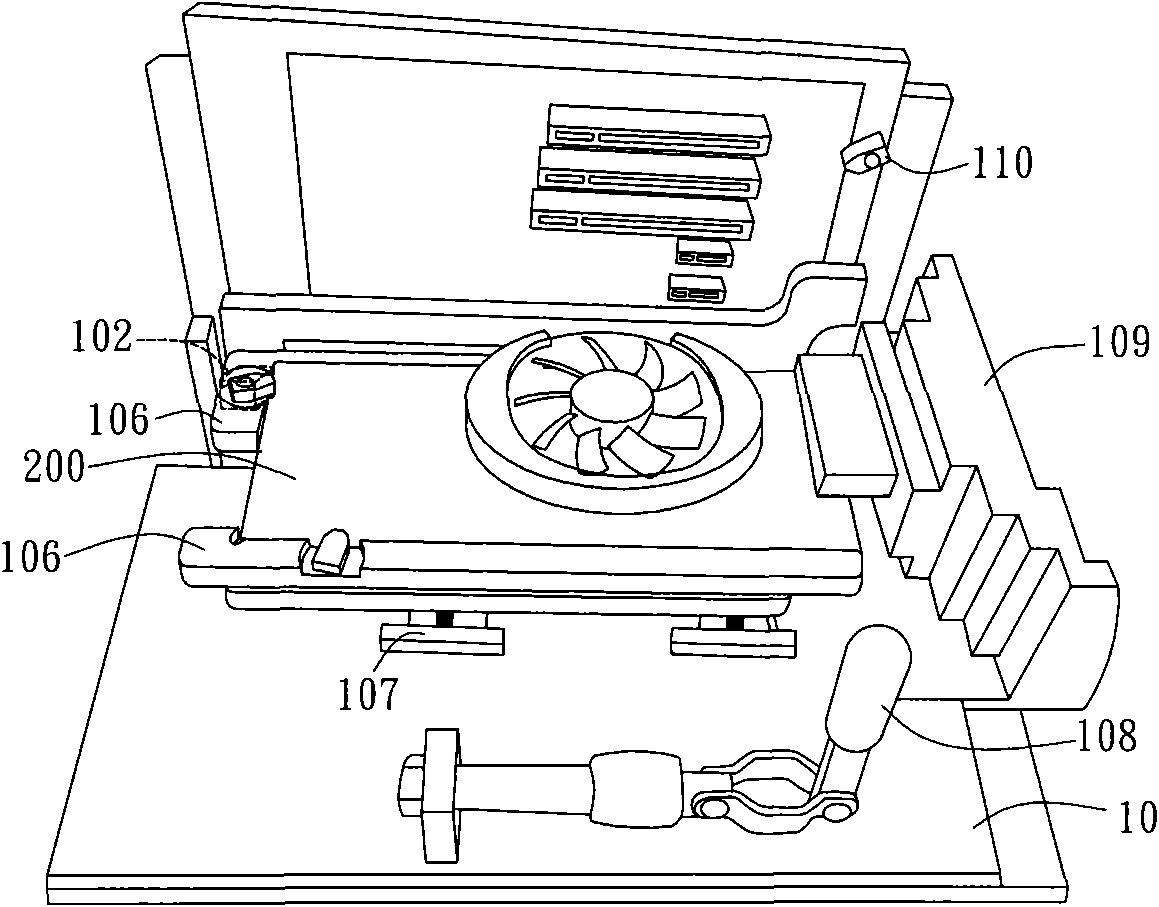

[0018] figure 1 It is a functional block diagram of a testing device in a preferred embodiment of the present invention.

[0019] The testing device 100 provided in this embodiment is used for testing a circuit board 200 to be tested. In this embodiment, the circuit board 200 to be tested is, for example, a display card, but the invention is not limited thereto. The circuit board under test 200 includes a first connection portion 201 . The test device 100 includes a mainboard 101 , a detection unit 102 , a control circuit 103 and a mode switching switch 105 , wherein the mainboard 101 includes a plurality of second connection parts 104 .

[0020] The circuit board under test 200 is coupled to the motherboard 101 . For example, the circuit board 200 to be tested can be coupled to one of the second connecting parts 104 of the motherboard 101 through the first connecting part 201 . Corresponding to circuit boards 200 to be tested with different specifications, the circuit boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com