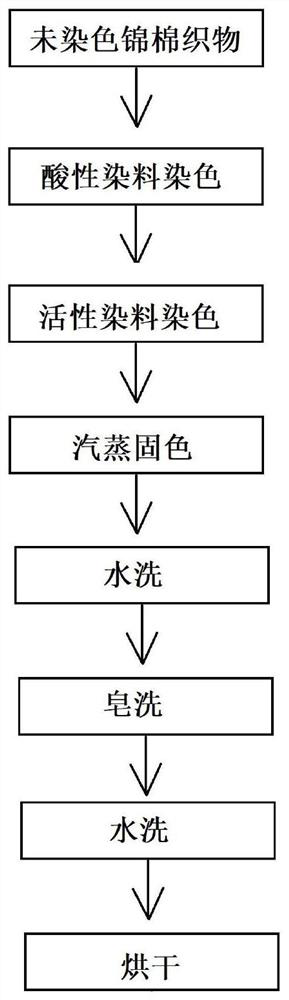

Dyeing process for nylon-cotton fabric

A nylon-cotton fabric and fabric dyeing technology is applied in the field of nylon-cotton fabric dyeing technology to achieve the effects of reducing usage, improving binding effect, and improving dyeing and color-fixing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

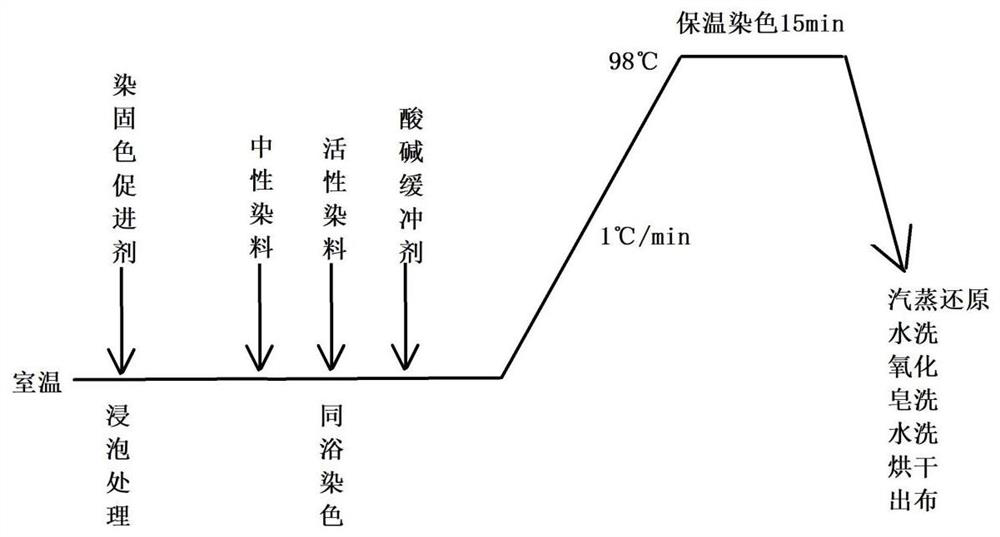

[0030] This embodiment provides a kind of polyamide-cotton fabric dyeing process, adopts one-bath one-step method dyeing to undyed polyamide-cotton fabric, comprises the following steps, as figure 2 Shown:

[0031] S1. Soaking treatment: put the nylon cotton fabric after desizing treatment into the dyeing vat, the liquor ratio is 1:6, add a dyeing and fixing accelerator to the dyeing vat at room temperature for soaking treatment for 1-2 hours, wherein the dyeing and fixing accelerator The dosage is 2g / L; Wherein, dyeing and fixation accelerator comprises the following components by weight: 28 parts of sodium sulfate, 18 parts of sodium acetate and 6 parts of dispersant; Oleic acid;

[0032] S2, dyeing in the same bath: add neutral dye 0.8% owf, reactive dye 1.2% owf to the dye vat, and add acid-base buffer to adjust the pH value to 10, then raise the temperature to 98°C at a rate of 1°C / min, and keep warm After dyeing for 15 minutes, drain the liquid by cooling down; among ...

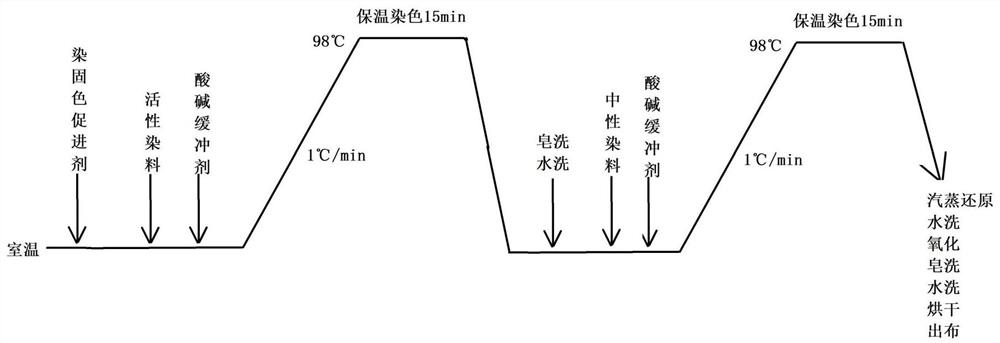

Embodiment 2

[0040] The present embodiment provides a kind of polyamide-cotton fabric dyeing process, adopts one-bath one-step method dyeing to undyed polyamide-cotton fabric, comprises the following steps:

[0041] S1. Soaking treatment: put the nylon cotton fabric after desizing treatment into the dyeing vat, the liquor ratio is 1:5, add a dyeing and fixing accelerator to the dyeing vat at room temperature for soaking treatment for 1-2 hours, wherein the dyeing and fixing accelerator The consumption is 4g / L; Wherein, dyeing and fixation accelerator comprises the following components by weight: 20 parts of sodium sulfate, 20 parts of sodium acetate and 8 parts of dispersing agent; Oleic acid;

[0042] S2. Dyeing in the same bath: add neutral dye 0.5% owf and reactive dye 2.5% owf to the dye vat, and add acid-base buffer to adjust the pH value to 9.5, then raise the temperature to 96°C at a rate of 1°C / min, and keep warm After dyeing for 15 minutes, drain the liquid by cooling down; among...

Embodiment 3

[0045] The present embodiment provides a kind of polyamide-cotton fabric dyeing process, adopts one-bath one-step method dyeing to undyed polyamide-cotton fabric, comprises the following steps:

[0046] S1. Soaking treatment: put the nylon cotton fabric after desizing treatment into the dyeing vat, the liquor ratio is 1:8, add a dyeing and fixing accelerator to the dyeing vat at room temperature for soaking treatment for 1-2 hours, wherein the dyeing and fixing accelerator The consumption is 5g / L; Wherein, dyeing and fixation accelerator comprises following components by weight: 34 parts of sodium sulfate, 16 parts of sodium acetate and 10 parts of dispersing agent; Oleic acid;

[0047] S2. Dyeing in the same bath: add neutral dye 3% owf and reactive dye 3% owf to the dye vat, and add acid-base buffer to adjust the pH value to 10.5, then raise the temperature to 100°C at a rate of 1.5°C / min, and keep warm After dyeing for 20 minutes, drain the liquid by cooling down; among th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com