Binder for lithium ion battery and preparation method of binder

A lithium-ion battery and binder technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of different components, reduce the compatibility of electrode materials and SEI films, etc., achieve small expansion rate, excellent stability, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method for a binder for lithium ion batteries, specifically comprising the following steps:

[0029] The binder includes 45 parts of polyvinyl fluoride, 20 parts of carboxymethyl cellulose gel, and 16 parts of modified sodium polyacrylate.

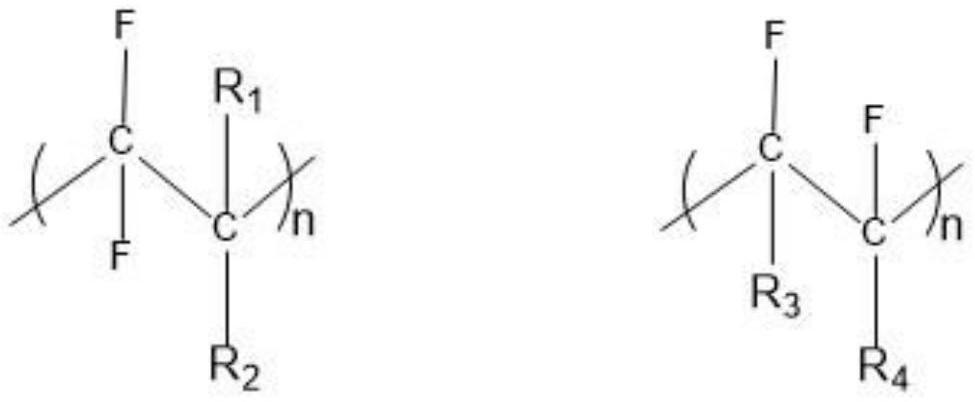

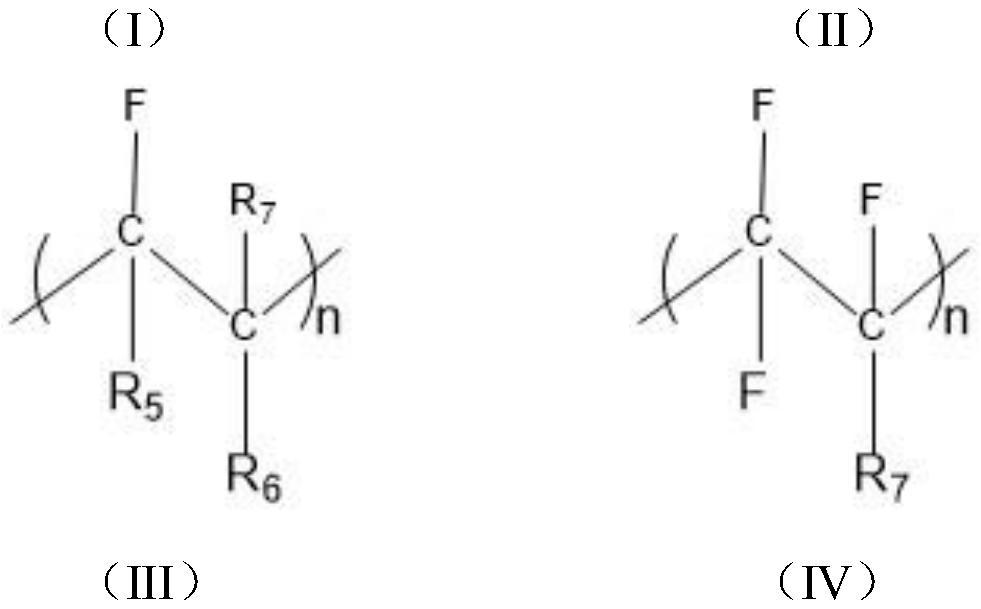

[0030] The structural unit represented by formula I of polyfluoroethylene accounts for 30% of the mass percentage of polyfluoroethylene, the structural unit represented by formula II accounts for 30% of polyfluoroethylene, and the structural unit represented by formula III accounts for 30% of polyfluoroethylene. The structural units account for 10% by mass of polyvinyl fluoride, and the structural units represented by formula IV account for 30% by mass of polyvinyl fluoride.

[0031] Among them, R in polyfluoroethylene 1 is C that is not substituted by a substituent 1 straight chain alkyl; R 2 is C that is not substituted by a substituent 2 The carboxylic acid group; R 3 is C that is not substituted by a substitue...

Embodiment 2

[0042] A preparation method for a binder for lithium ion batteries, specifically comprising the following steps:

[0043] The binder includes 60 parts of polyvinyl fluoride, 35 parts of carboxymethyl cellulose gel, and 22 parts of modified sodium polyacrylate.

[0044] The structural unit represented by the polyfluoroethylene formula I accounts for 45% of the polyfluoroethylene mass percentage, the structural unit represented by the formula II accounts for 20% of the polyfluoroethylene mass percentage, and the polyfluoroethylene represented by the formula III The structural units account for 15% by mass of polyvinyl fluoride, and the structural units represented by formula IV account for 20% by mass of polyvinyl fluoride.

[0045] Among them, R in polyfluoroethylene 1 is C that is not substituted by a substituent 4 straight chain alkyl; R 2 is C that is not substituted by a substituent 6 The carboxylic acid group; R 3 is C that is not substituted by a substituent 8 strai...

Embodiment 3

[0056] A preparation method for a binder for lithium ion batteries, specifically comprising the following steps:

[0057] The binder includes 50 parts of polyvinyl fluoride, 25 parts of carboxymethyl cellulose gel, and 18 parts of modified sodium polyacrylate.

[0058] The structural unit represented by the polyfluoroethylene formula I accounts for 35% of the polyfluoroethylene mass percentage, the structural unit represented by the formula II accounts for 25% of the polyfluoroethylene mass percentage, and the polyfluoroethylene represented by the formula III The structural units account for 10% by mass of polyvinyl fluoride, and the structural units represented by formula IV account for 30% by mass of polyvinyl fluoride.

[0059] Among them, R in polyfluoroethylene 1 is C that is not substituted by a substituent 3 straight chain alkyl; R 2 is C that is not substituted by a substituent 3 The carboxylic acid group; R 3 is C that is not substituted by a substituent 5 strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com