Preparation method of silicon-carbon composite negative electrode material, and prepared negative electrode material

A negative electrode material, silicon carbon composite technology, applied in the field of lithium ion batteries, can solve the problems of uneven coating, incomplete coating, poor cycle stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing a silicon-carbon composite negative electrode material and the prepared negative electrode material, comprising the following steps:

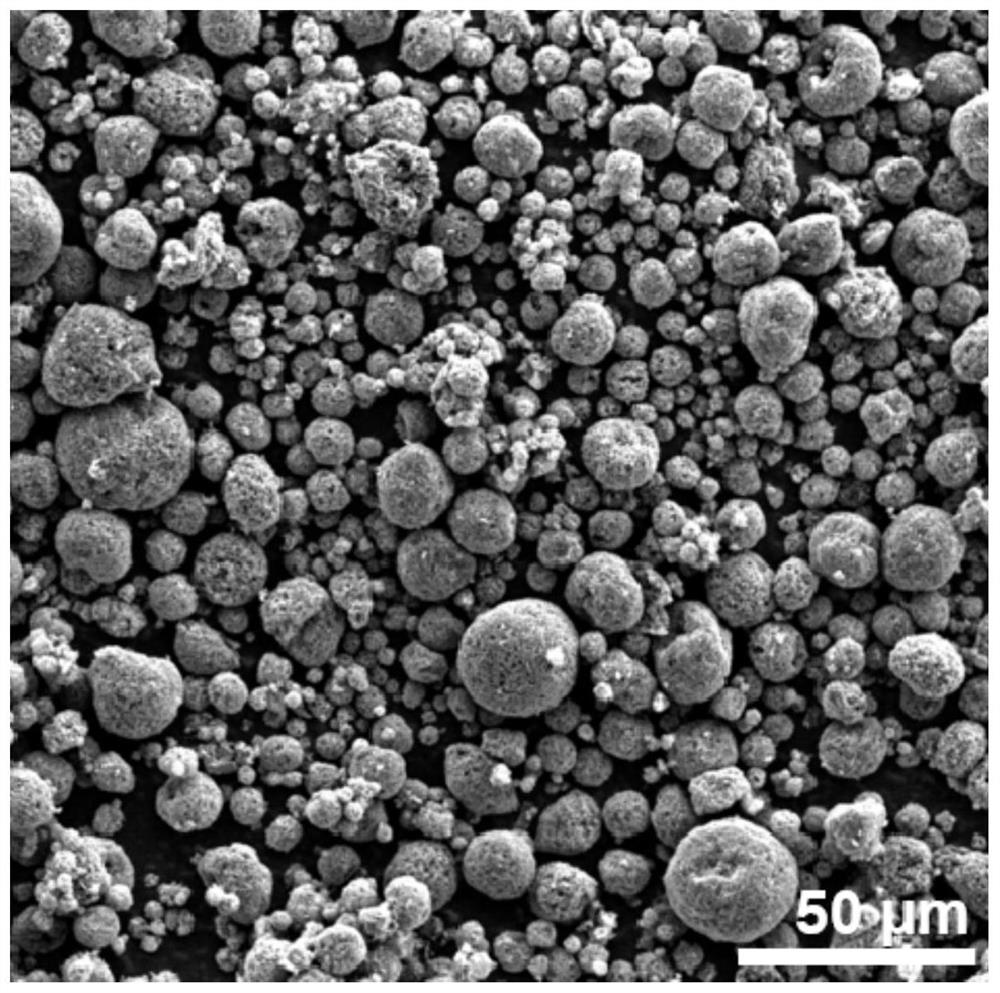

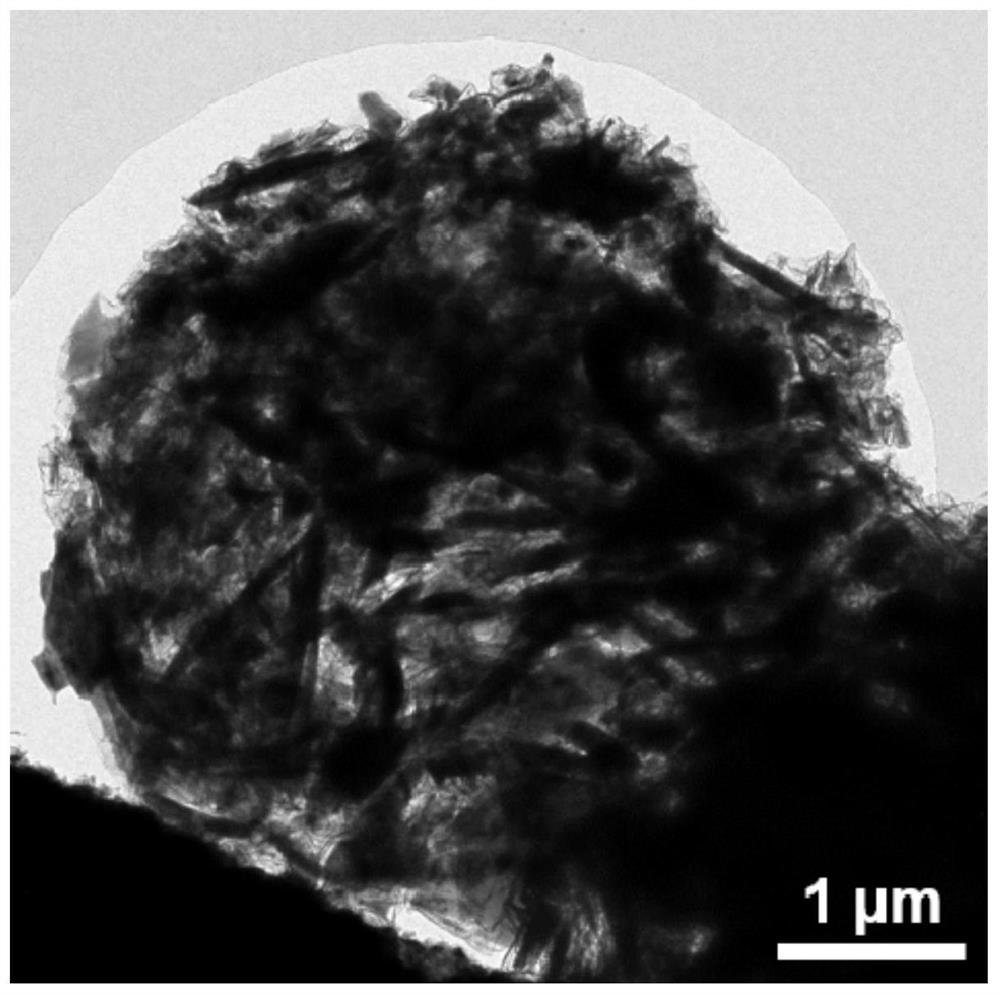

[0044] 1) Micron-sized industrial silicon powder is washed with deionized water, dispersed and dried with sodium carboxymethylcellulose dispersant, crushed by a crusher, and classified on a jet mill equipped with an air cyclone to obtain 0.5-3µm particles Precursor silicon powder;

[0045]2) Put step 1) precursor silicon powder in a rotary furnace, raise the temperature to 800°C, feed a mixed gas containing water vapor and argon, the content of water vapor is 10%, the content of argon is 90%, and the calcination process is 6.5 h, prepared Si / SiO 2 composite powder;

[0046] 3) At room temperature, add polyvinyl alcohol to a certain amount of deionized water (solid content 0.01g / mL), stir and heat up to 95°C, and obtain a transparent glue after constant temperature for 0.5h;

[0047] 4) Combine step 2) Si / SiO 2 ...

Embodiment 2

[0076] A method for preparing a silicon-carbon composite negative electrode material and the prepared negative electrode material, comprising the following steps:

[0077] 1) Micron-sized industrial silicon powder is washed with deionized water, dispersed and dried with sodium dodecylbenzenesulfonate dispersant, crushed by a crusher, and classified on a jet mill equipped with an air cyclone to obtain 0.5- 3µm precursor silicon powder;

[0078] 2) Put step 1) precursor silicon powder in a rotary furnace, raise the temperature to 800°C, feed a mixed gas containing water vapor, oxygen and argon, the water vapor content is 8%, the oxygen content is 2%, and calcined 9.75h, prepared Si / SiO 2 composite powder;

[0079] 3) At room temperature, add starch to deionized water (solid content 0.01g / mL), stir and heat up to 95°C, and keep the temperature for 0.5h to obtain a transparent glue;

[0080] 4) Combine step 2) Si / SiO 2 The composite powder is added to the transparent glue solu...

Embodiment 3

[0087] A high-performance silicon-carbon composite negative electrode material and a preparation method thereof, comprising the following steps:

[0088] 1) Micron-sized industrial silicon powder is washed with deionized water, dispersed and dried with oleylamine dispersant, crushed by a crusher, and classified on a jet mill equipped with an air cyclone to obtain a precursor silicon powder of 0.5-3 µm ;

[0089] 2) Put step 1) precursor silicon powder in a rotary furnace, raise the temperature to 800°C, feed a mixed gas containing water vapor, oxygen and argon, the water vapor content is 8%, the oxygen content is 2%, and calcined 9.75h, prepared Si / SiO 2 composite powder;

[0090] 3) At room temperature, add polyacrylic acid to deionized water (solid content 0.01g / mL), stir and heat up to 95°C, and obtain a transparent glue after constant temperature for 0.5h;

[0091] 4) Combine step 2) Si / SiO 2 The composite powder is added to the transparent glue solution in step 3), wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com