Doped cobaltosic oxide and preparation method thereof

A doped cobalt tetroxide technology, which is applied in the field of doped cobalt tetroxide and its preparation, can solve the problems of inapplicability to the preparation of doped single crystal cobalt tetroxide, low compaction density of positive electrode materials, uneven distribution of doping elements, etc., to achieve The effect of dense particles, fine crystal nuclei, and accelerated growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

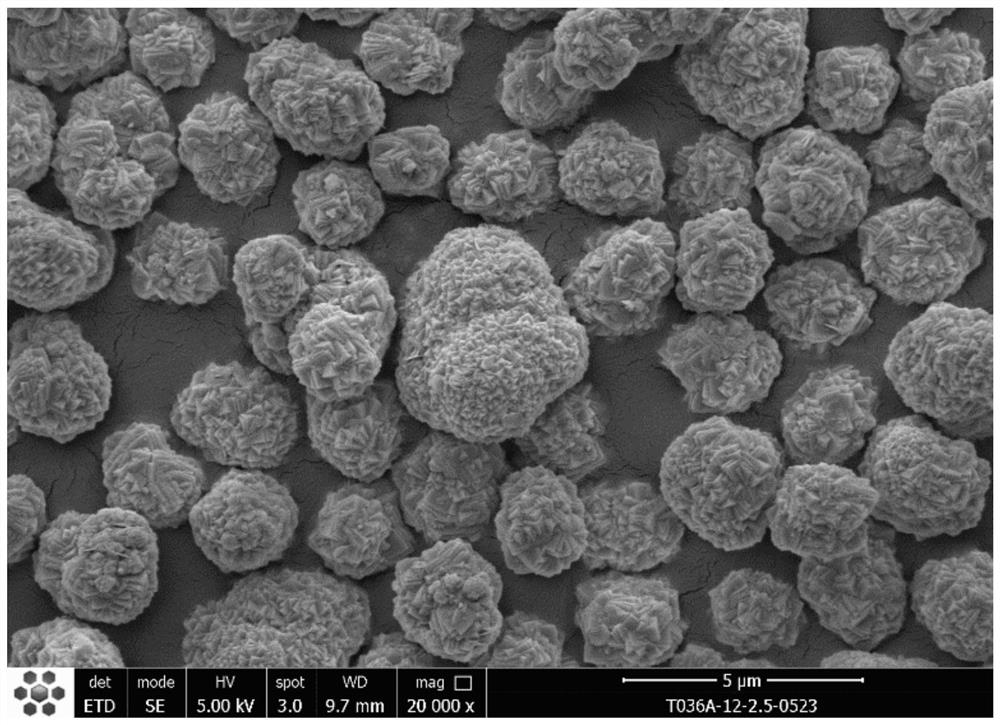

[0057] A kind of doping type tricobalt tetroxide precursor of the present invention, molecular formula is Co 2.97 Al 0.027 o 4 , the morphology is single crystal particles, the primary grain size is 400nm, the half-maximum width of the 311 crystal plane is 0.25, and the particle size of doped cobalt tetroxide is D 10 = 2.72 μm, D 50 = 4.52 μm, D 90 =6.73μm; particle size distribution (D 90 -D 10 ) / D 50 =0.88, tap density TD=1.77g / cm 3 , bulk density = 1.25g / cm 3 , (BET-2.5) / (TD-1.5)=0.91.

[0058] The preparation method of the doped tricobalt tetroxide precursor of this embodiment comprises the following steps:

[0059] (1) According to Co 2.97 Al 0.027 o 4 The stoichiometric ratio preparation metal ion total concentration (aluminum ion and cobalt ion) is the soluble mixed salt solution of 110g / l;

[0060] (2) Add 10L of pure water in the 50L reactor as the bottom liquid of the reactor, pump a certain amount of ammonium bicarbonate solution into the bottom liquid ...

Embodiment 2

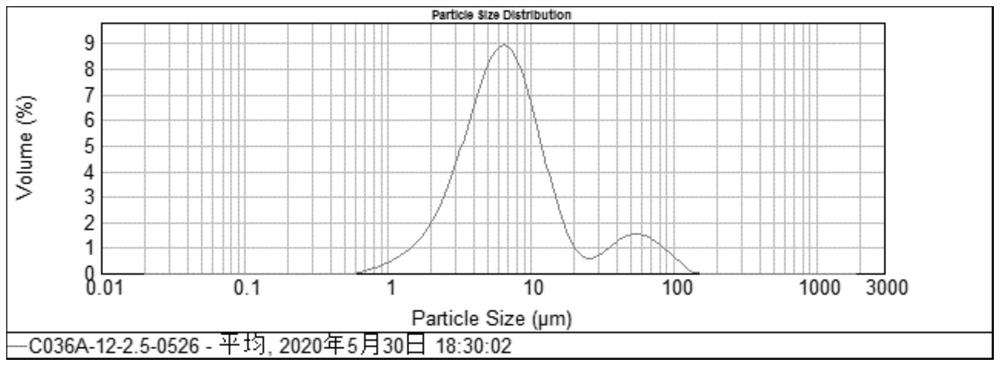

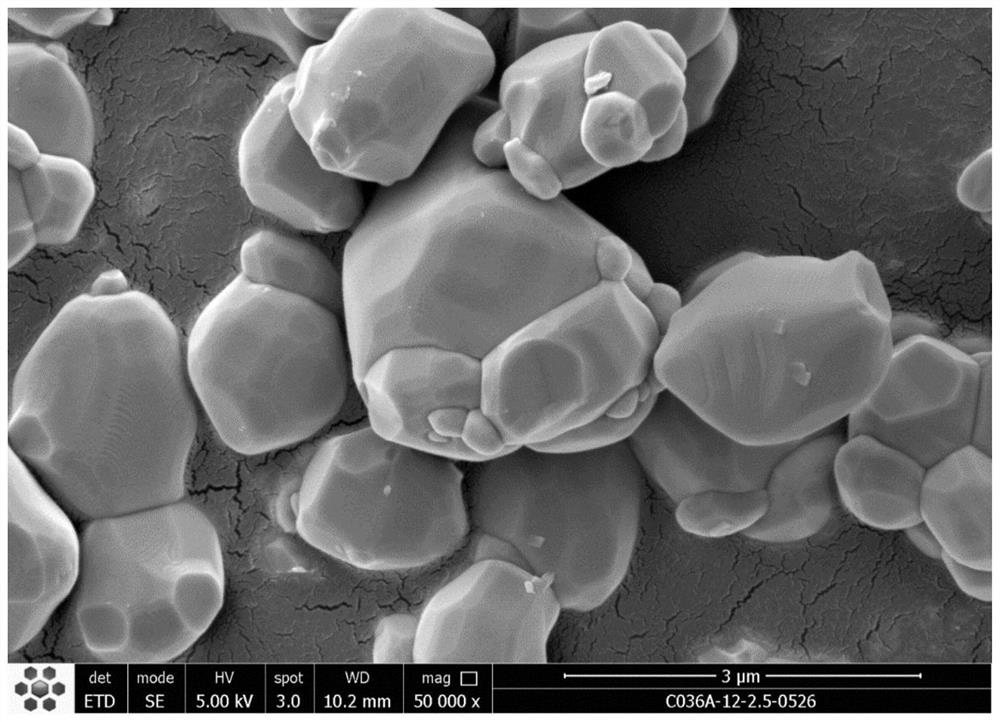

[0069] A kind of doping type cobalt tetroxide of the present invention, molecular formula is Co 2.97 Al 0.02 Mg 0.01 o 4 , its morphology is similar to single crystal aggregates, the primary grain size is 300nm, the half-maximum width of the 311 crystal plane is 0.3, and the particle size of doped tricobalt tetroxide is D 10 = 2.22 μm, D 50 = 4.3 μm, D 90 =6.42μm; particle size distribution (D 90 -D 10 ) / D 50 =0.97, tap density TD=2.05g / cm 3 , bulk density = 1.25g / cm 3 , (BET-2.5) / (TD-1.5)=0.73.

[0070] The preparation method of the doped tricobalt tetroxide of the present embodiment comprises the following steps:

[0071] (1) According to Co 2.97 Al 0.02 Mg 0.01 o 4 The stoichiometric ratio, preparation metal ion total concentration (cobalt ion and doping metal ion) is the soluble mixed salt solution of 110g / l;

[0072] (2) Add 10L of pure water in the 50L reactor as the bottom liquid of the reactor, pump a certain amount of ammonium bicarbonate solution into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com