A kind of high pigment carbon black-polyamide color masterbatch and preparation method thereof

A technology of high-pigment carbon black and polyamide, which is applied in the field of polymer materials, can solve the problems of product gloss and color fastness, and reduce the dispersion effect of carbon black, achieve high compatibility, reduce alkalinity, and enhance black effect of gloss and gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] 1.2 Preparation of dispersant

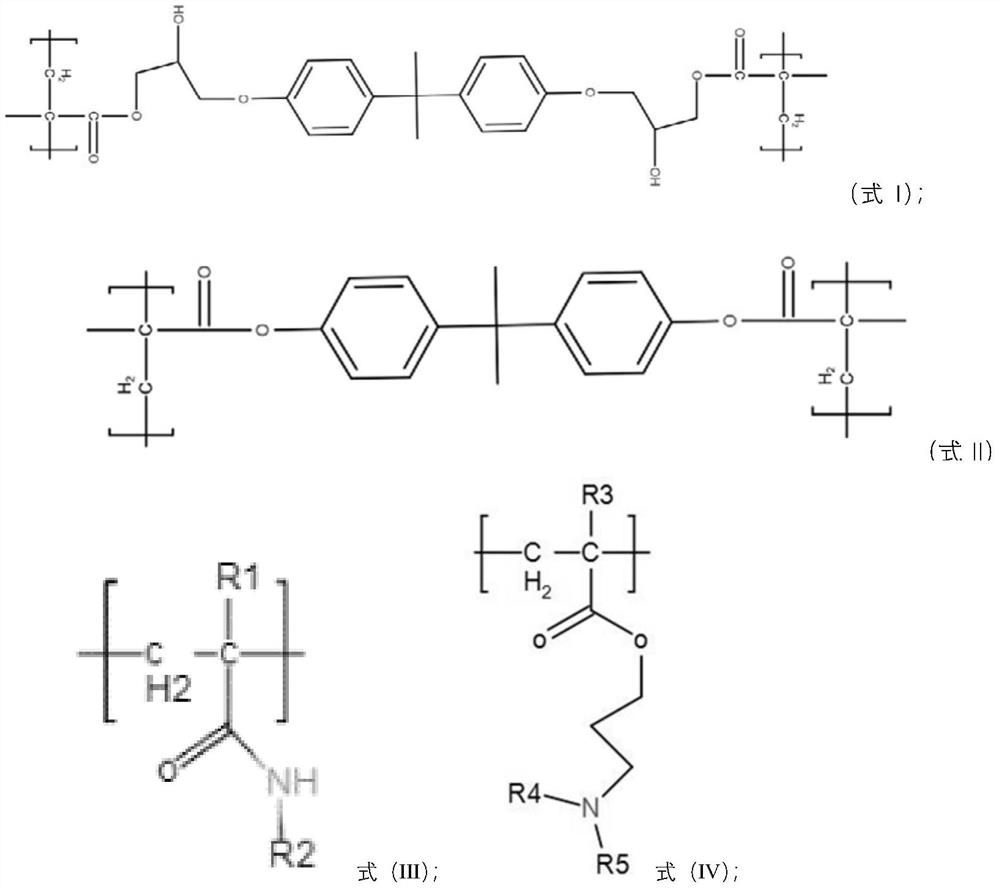

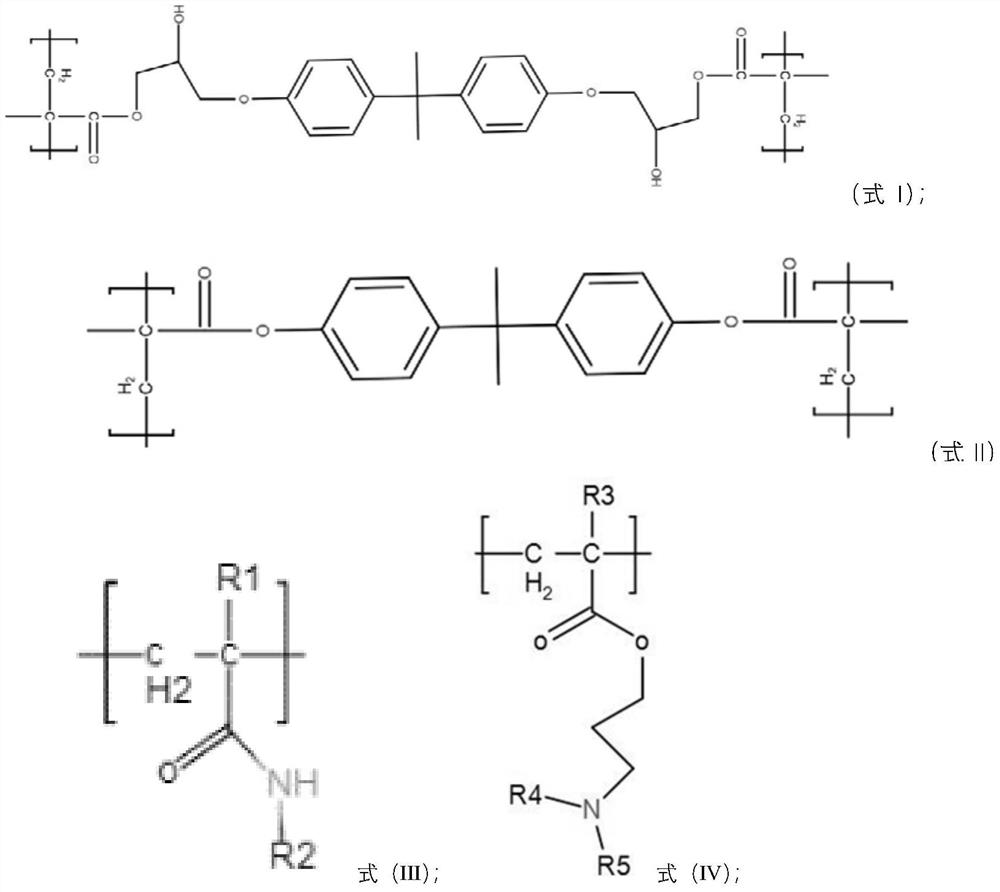

[0047] Bisphenol A dimethacrylate or bisphenol A glycidyl dimethacrylate monomer, acrylamide monomer, and acrylate monomer are in molar ratio (1-3): (2-5): (6-8) Put it into the reactor, feed N2, heat to 130-140°C for bulk polymerization, and the reaction time is 30-120min to prepare the dispersant.

[0048] The specific method is as follows:

[0049] 1.2.1 Add bisphenol A dimethacrylate, N-hydroxyhexylmethacrylamide, and diethylaminopropyl acrylate into the reactor according to the molar ratio of 2:5:6, feed N2, and heat to 130°C Carry out bulk polymerization, the reaction time is 60min, can prepare dispersant I, weight-average molecular weight 6340.

[0050] 1.2.2 Bisphenol A dimethacrylate glycidyl ester monomer, N-heptylacrylamide, and acrylate monomer (R3 is methyl, R4 and R5 are phenyl) according to the molar ratio of 1:3: 6. Put it into the reactor, feed N2, heat to 140°C for bulk polymerization, and the reaction time is 70 minu...

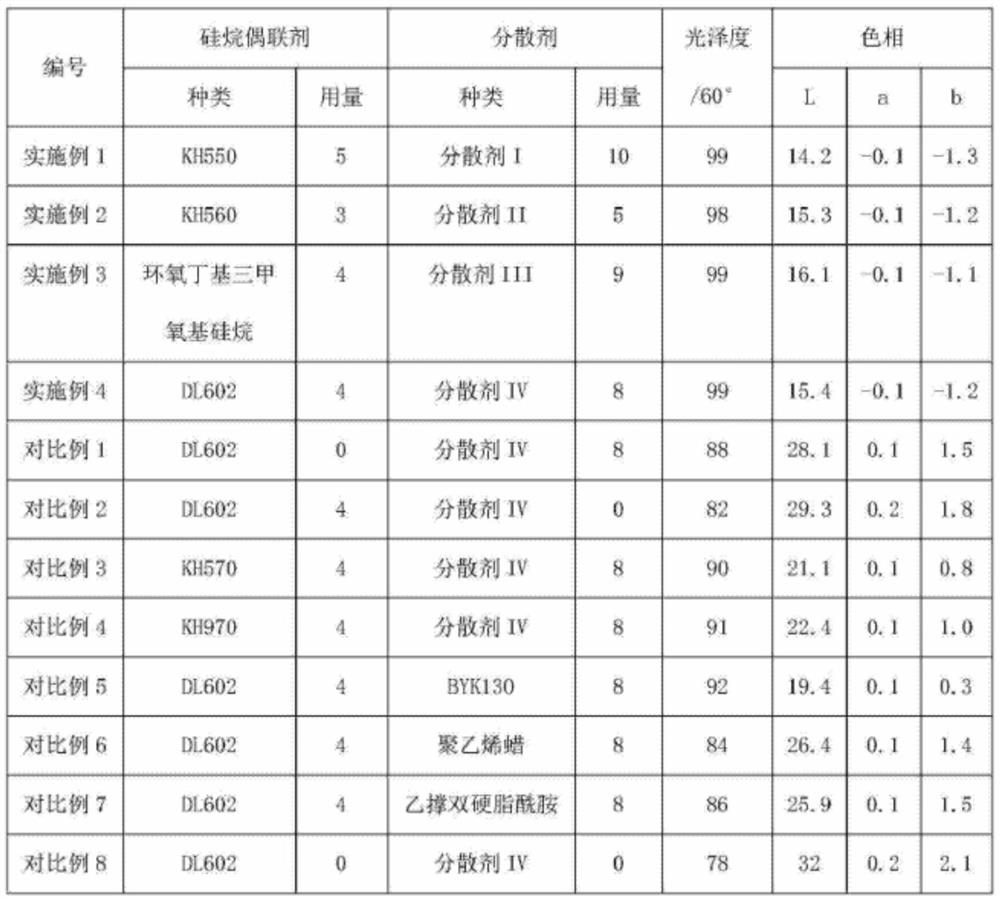

Embodiment 1

[0054] The present embodiment prepares a kind of high-pigment carbon black-polyamide color masterbatch, comprises the raw material of following weight portion: 80 parts of high-pigment carbon black; 80 parts of polyamide resins; 10 parts of dispersants; 5 parts of silane coupling agents; 0.8 parts of oxygen agent; the polyamide resin is PA66, the dispersant is dispersant I, and the silane coupling agent is γ-aminopropyltriethoxysilane (KH550).

[0055] The preparation method comprises the following steps:

[0056] (1) material preparation

[0057] Take each raw material according to the following parts by weight, 80 parts of high pigment carbon black; 80 parts of polyamide resin; 10 parts of dispersant; 5 parts of silane coupling agent; 0.8 part of antioxidant;

[0058] (2) High pigment carbon black modification

[0059] Mix high-pigment carbon black and silane coupling agent evenly, and ball mill at 0-10°C for 40 minutes to prepare high-pigment carbon black modified by sila...

Embodiment 2

[0065] The present embodiment prepares a kind of high-pigment carbon black-polyamide color masterbatch, comprises the raw material of following weight portion: 40 parts of high-pigment carbon black; 100 parts of polyamide resins; 5 parts of dispersants; 3 parts of silane coupling agents; 0.6 parts of oxygen agent; the polyamide resin is PA46, the dispersant is dispersant II, and the silane coupling agent is γ-glycidyl etheroxypropyl trimethoxysilane (KH560).

[0066] The preparation method comprises the following steps:

[0067] (1) material preparation

[0068] Take each raw material according to the following parts by weight, 40 parts of high pigment carbon black; 100 parts of polyamide resin; 5 parts of dispersant; 3 parts of silane coupling agent; 0.6 part of antioxidant;

[0069] (2) High pigment carbon black modification

[0070] Mix high-pigment carbon black and silane coupling agent evenly, and ball mill at 0-10°C for 20 minutes to prepare high-pigment carbon black m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com