A kind of liquid polishing wax for stainless steel and its preparation method and application

A technology of stainless steel and polishing wax, which is applied in the direction of grinding/polishing equipment, polishing compositions containing abrasives, manufacturing tools, etc. It can solve problems such as system instability, poor compatibility of critical surface tension with human body, and harmful alkaline substances , to achieve good fluidity, excellent spreading and adhesion performance, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

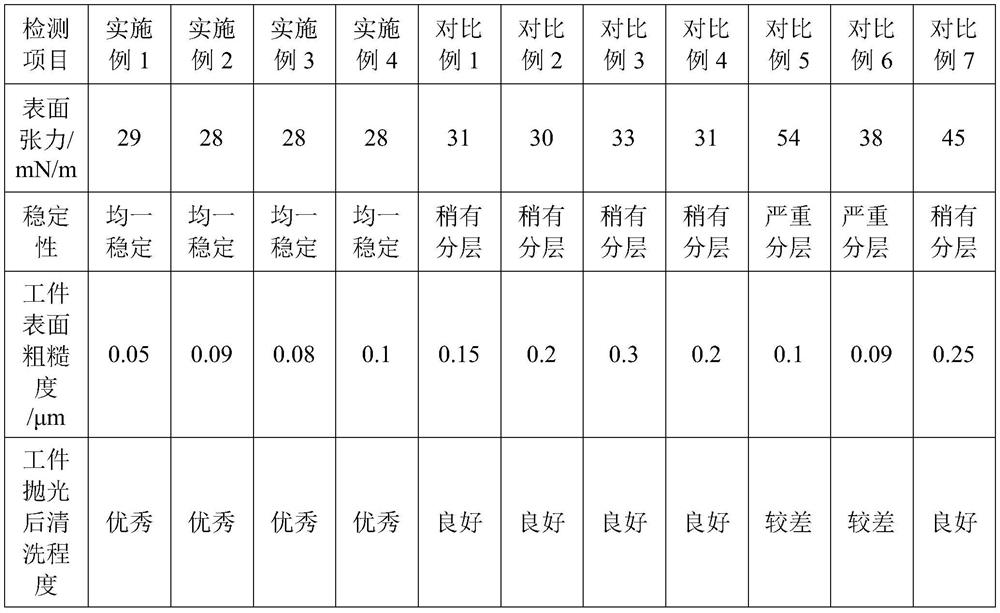

Examples

Embodiment 1

[0057] This example provides a liquid polishing wax for stainless steel, which consists of the following components in terms of mass percentage:

[0058] (1) Abrasive 20%

[0059] (2) Lubricant 23%

[0060] (3) Auxiliary 17%

[0061] (4) Water 40%.

[0062] Wherein, in terms of mass percentage, the abrasive includes 6% of α-alumina with a particle size of 200-210nm, 5% of zirconia with a particle size of 0.6-0.8μm, and 9% of cerium oxide with a particle size of 20-30nm.

[0063] In terms of mass percentage, the lubricant comprises 5% of stearic acid, 7% of oleic acid, 1% of palm wax and 10% of liquid paraffin.

[0064] In terms of mass percentage, the additives include 11% of phenylethylphenol polyoxyethylene ether, 1% of sorbitan fatty acid ester, 3% of sodium lignosulfonate, 1.5% of bentonite, and 0.5% of xanthan gum .

[0065] Above-mentioned a kind of liquid polishing wax for stainless steel, preparation method is carried out by the following steps:

[0066] (1) Add ...

Embodiment 2

[0070] This example provides a liquid polishing wax for stainless steel, which consists of the following components in terms of mass percentage:

[0071] (1) Abrasive 17%

[0072] (2) Lubricant 22%

[0073] (3) Auxiliary 15%

[0074] (4) Water 46%.

[0075] Wherein, in terms of mass percentage, the abrasive includes 4% of α-alumina with a particle size of 200-210nm, 3% of zirconia with a particle size of 0.6-0.8μm, and 10% of cerium oxide with a particle size of 20-30nm.

[0076] In terms of mass percentage, the lubricant includes 2% castor oil, 5% sulfurized fatty acid ester, 3% palm wax, 11% liquid paraffin, and 1% microcrystalline wax.

[0077] In terms of mass percentage, the auxiliary agent includes 1% sorbitan fatty acid ester, 7% fatty acid polyoxyethylene ester, 1% glyceryl monostearate, 2% polycarboxylate, alkyl naphthalene sulfonate Sodium phosphate 1%, magnesium aluminum silicate 2%, tallow amine polyoxyethylene ether 1%.

[0078] A kind of liquid polishing wax...

Embodiment 3

[0080] This example provides a liquid polishing wax for stainless steel, which consists of the following components in terms of mass percentage:

[0081] (1) Abrasive 17%

[0082] (2) Lubricant 23%

[0083] (3) Auxiliary 17%

[0084] (4) Water 43%.

[0085] Wherein, in terms of mass percentage, the abrasive includes 4% of α-alumina with a particle size of 200-210nm, 3% of zirconia with a particle size of 0.6-0.8μm, and 10% of cerium oxide with a particle size of 20-30nm.

[0086] In terms of mass percentage, the lubricant includes 2% of oleic acid, 4% of sulfurized fatty acid ester, 7% of rice bran wax and 10% of liquid paraffin.

[0087] In terms of mass percentage, the auxiliary agent includes 9% of fatty alcohol block polyether, 1% of sorbitan fatty acid ester, 1% of glyceryl monostearate, 2% of polycarboxylate, alkyl naphthalene Sodium sulfonate 1%, starch 2%, xanthan gum 1%.

[0088] A kind of liquid polishing wax for stainless steel described above, the preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com