Synthesis and application of rare earth layered thermocatalytic material

A technology of thermal catalysis and rare earth hydrate, which is applied in the preparation/treatment of rare earth metal compounds, rare earth metal sulfate, catalyst activation/preparation, etc., and can solve the problems of large demand for aromatic compounds and large consumption of fossil energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

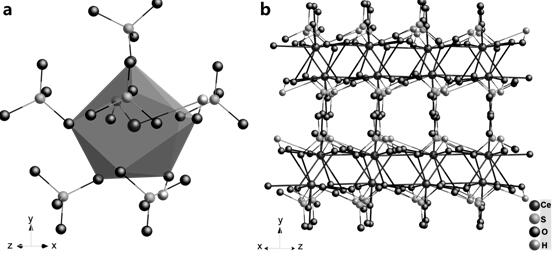

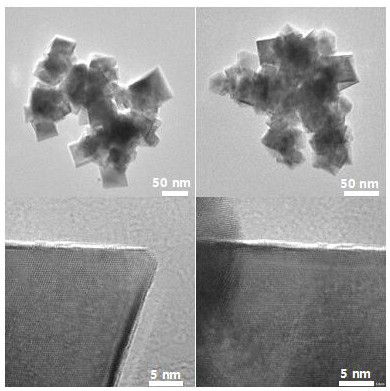

[0040] 1) the CeCl 3 ·7H 2 O and (NH 4 ) 2 SO 4 Dissolve equimolar amounts in deionized water (the ratio of rare earth hydrate to water is 0.08-0.17 mmol·mL -1 ), then transfer the resulting solution to a polytetrafluoroethylene liner, add triethylamine dropwise to the solution with a pipette gun to adjust the pH of the solution, and stir at room temperature to obtain a uniform mixture, control the solution pH=7-11, preferably pH=7.

[0041] 2) Put the reaction kettle with the above mixed solution in an oven, react at a constant temperature at 80 °C for 3 h, cool to room temperature naturally, and filter to obtain a solid product;

[0042] 3) Wash the above solid product with water and ethanol several times, put the obtained solid in an oven, keep it at 40 ℃ for several hours (5-9 hours), and dry the sample to obtain a white solid powder.

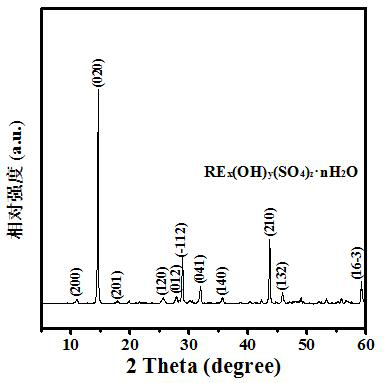

[0043] Product marked as RE x (OH) y (SO 4 ) z ·nH 2 O, preferably, x=1, y=1, z=1, n=0-3, ie RE(OH)SO 4 ·nH 2 O, x=1, y=1, z=...

Embodiment 2

[0053] Carry out according to the mode of embodiment 1, difference is, in step 1), will add triethylamine and add ammonia water instead.

Embodiment 3

[0055] Proceed in the same manner as in Example 1, except that the reaction temperature in step 2) is 85°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com