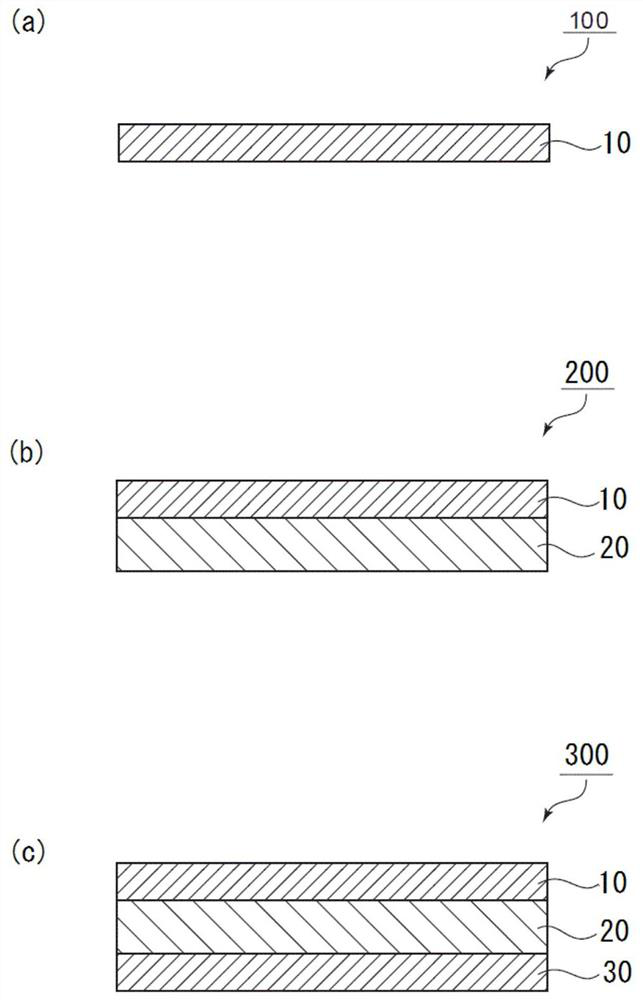

Adhesive sheet

An adhesive sheet, adhesive surface technology, applied in the direction of adhesive types, hydrocarbon copolymer adhesives, adhesives, etc. Deformation of the agent layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

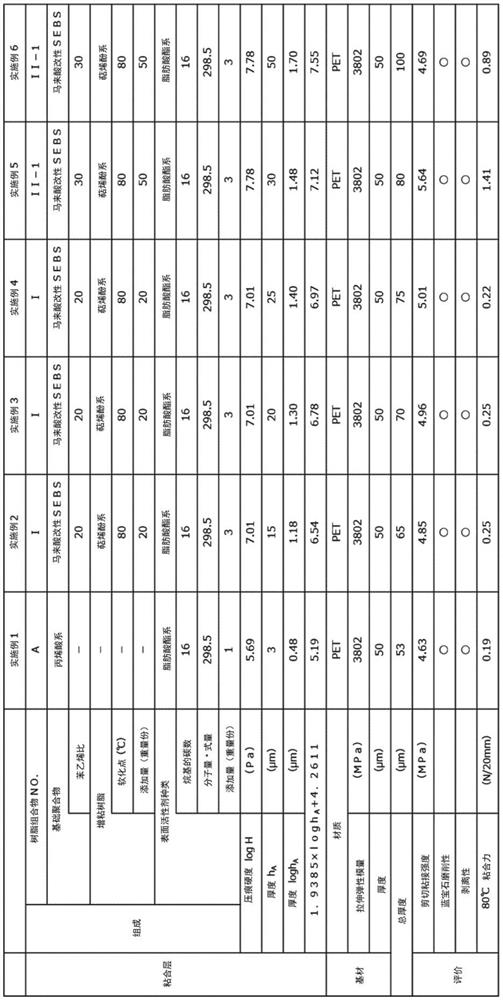

[0113]The present invention will be specifically described with reference to the embodiments, but the present invention is not limited by the examples. The evaluation methods in the examples are as follows. It should be noted that in the following evaluation, the adhesive sheet after the isolation body is removed. Further, in the embodiment, "parts" and "%" are the weight reference as long as it is not particularly explained.

[0114]

[0115]In the following evaluation method, the bonding of the adhesive layer (and other adhesive layers) is carried out after pertocking of the isolation of the fitting surface.

[0116](1) Shear bonding strength

[0117]For the adhesive sheet (size: 20 mm × 20 mm) obtained in the examples and comparative examples, the face sticker is attached to the predetermined base (e.g., 20 mm × 20 mm silicon chip) and fixed, The surface of the adhesive layer of the adhesive sheet was formed of a 5 mm × 5 mm silicon chip, and the silicon chip was thermally pressed for 1 minu...

manufacture example 1

[0138][Production Example 1] Preparation of Resin Composition (I)

[0139]Malenic acid modified styrene block copolymer (a) (SEBS: styrene) (SEBS: styrene) = 20 / 80, acid value: 10 (mg) -CH3ONA / G), Made of Chemical Co., Ltd. 80 ° C) 20 parts by weight, epoxy crosslinking agent (Mitsubishi Gas Chemical Co., Ltd., trade name "tetrad-c") 3 parts by weight, fatty acid ester surfactant (manufactured by Huang Co., Ltd. "ExeParl IPP ", molecular weight: 298.5, alkyl number: 16) 3 parts by weight, and a resin composition (I) (mixture) is prepared as a solvent.

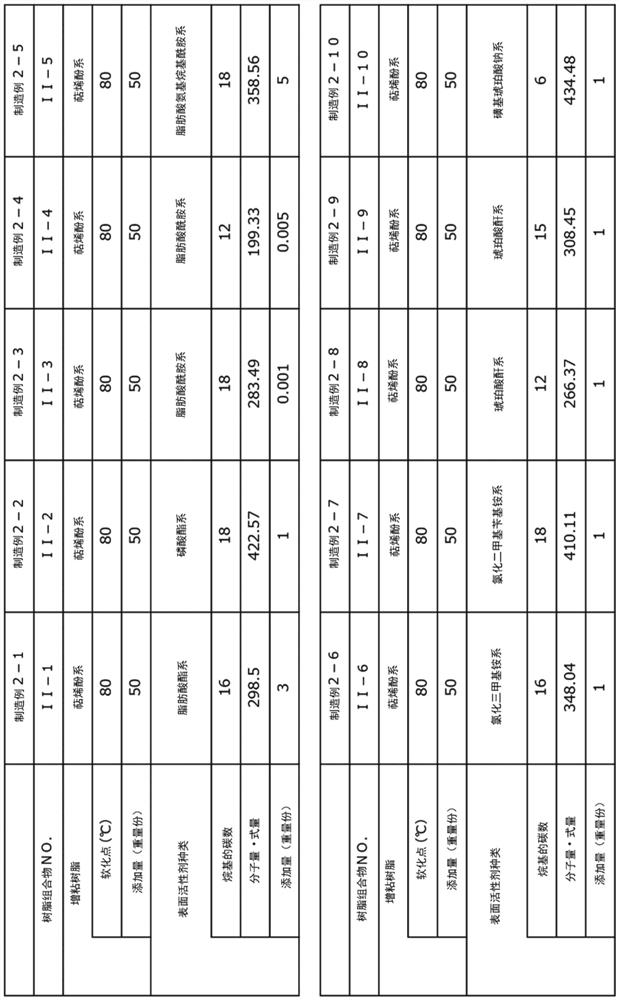

manufacture example 2-1

[0140][Production Example 2-1] Preparation of Resin Composition (II-1)

[0141]Malenic acid modified styrene block copolymer (B) (SEBS) (SEBS: styrene) = 30 / 70, acid value: 10 (mg) = 30 / 70, acid value: 10 (mg) -CH3ONA / G), Asahi Chemical Co., Ltd., manufactured, trade name "Tuftec M1913") 100 parts by weight, terpene phenolic tackifier (Yasuhara Chemical Co., LTD. Manufacturing, trade name "ys polystar T80") 50 parts by weight , Epoxy Crosslinking Agent (Mitsubishi Gas Chemical Co., Ltd., trade name "tetrad-c") 3 parts by weight, fatty acid ester surfactant (manufactured by Huang Co., Ltd., trade name "ExeParl IPP", molecular weight: 298.5 , The number of carbon of the alkyl group: 16) 3 parts by weight, and a resin composition (II-1) (mixture) was prepared as a solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com