Preparation method of baking-free inorganic composite membrane

A technology of inorganic composite membrane and mixed slurry, applied in cement production and other directions, can solve the problems of high production cost and energy consumption, undiscovered, unfavorable promotion and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

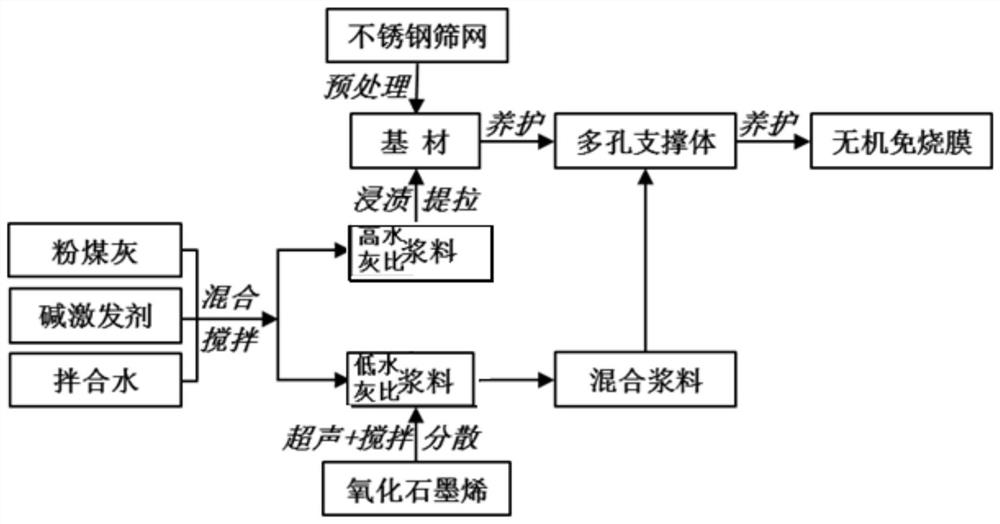

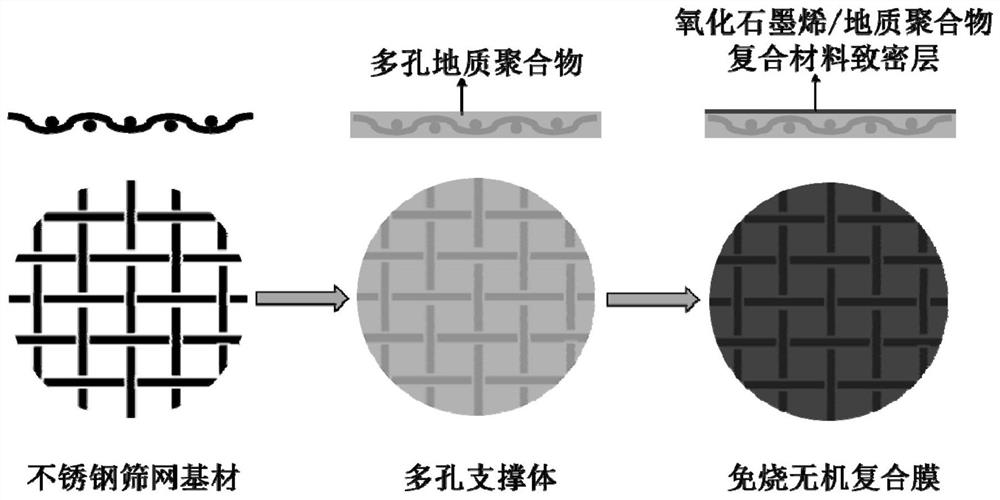

Method used

Image

Examples

Embodiment 1

[0042] (1) take by weighing 10g fly ash;

[0043] (2) Take by weighing 3.2g sodium hydroxide, put in the beaker;

[0044] (3) Weigh 8g and 4g of deionized water and put them into beakers respectively;

[0045] (4) Dissolve the sodium hydroxide taken by step (2) in the deionized water taken by step (3), stir and cool to room temperature to obtain two parts of alkali activator solutions respectively; the first part of deionized water consumption 8g, the second deionized water consumption is 4g;

[0046] (5) two parts of alkali activator solutions of step (4) are placed in a blender, the fly ash weighed in step (1) is placed in a blender, stirred, and two parts of uniform geopolymer slurry are respectively obtained; Among them, the amount of deionized water 8g is called high gray-water ratio, and the amount of deionized water 4g is called low gray-water ratio;

[0047] (6) Cut the 40-mesh square-hole stainless steel screen into a circle with a diameter of 50mm, place it in a b...

Embodiment 2

[0053] (1) take by weighing 10g fly ash;

[0054] (2) Take by weighing 2.8g sodium hydroxide, put in the beaker;

[0055] (3) Weigh 7g of deionized water and 5g of deionized water and put them into beakers respectively;

[0056] (4) Dissolve the sodium hydroxide weighed in step (2) in the deionized water weighed in step (3), stir and cool to room temperature to obtain two parts of alkali activator solutions respectively, the first part of deionized water consumption 7g, the second deionized water consumption is 5g;

[0057] (5) two parts of alkali activator solutions of step (4) are placed in a blender, the fly ash weighed in step (1) is placed in a blender, stirred, and two parts of uniform geopolymer slurry are respectively obtained; Among them, the amount of deionized water 7g is called high gray-water ratio, and the amount of deionized water 5g is called low gray-water ratio.

[0058] (6) Cut the 40-mesh square-hole stainless steel screen into a circle with a diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com