Multi-metal in-situ doped desulfurizing agent based on low-coalification-degree inferior coal and preparation method thereof

A low coalification degree, in-situ doping technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problem of expensive raw materials, achieve rich raw material reserves, reduce preparation costs, and improve adsorption performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) According to the industrial analysis and elemental analysis of coal, low coalification degree coals containing polymetallic elements are screened out, wherein carbon content: 60wt%, ash content: 10wt%, iron content: 0.6wt%, calcium content: 0.9wt% , magnesium content: 0.2wt%;

[0025] (2) drying, crushing and sieving the screened low-coalification degree coal to obtain pulverized coal, the particle size of which is 0.1-1.0mm;

[0026] (3) Under a nitrogen atmosphere, carbonize the coal powder in a fluidized bed carbonization furnace, wherein the nitrogen flow rate is 200mL / min, the heating rate: 30°C / min, the carbonization temperature: 900°C, and the carbonization time: 30min. Desulfurization agent doped in situ with iron, calcium and magnesium.

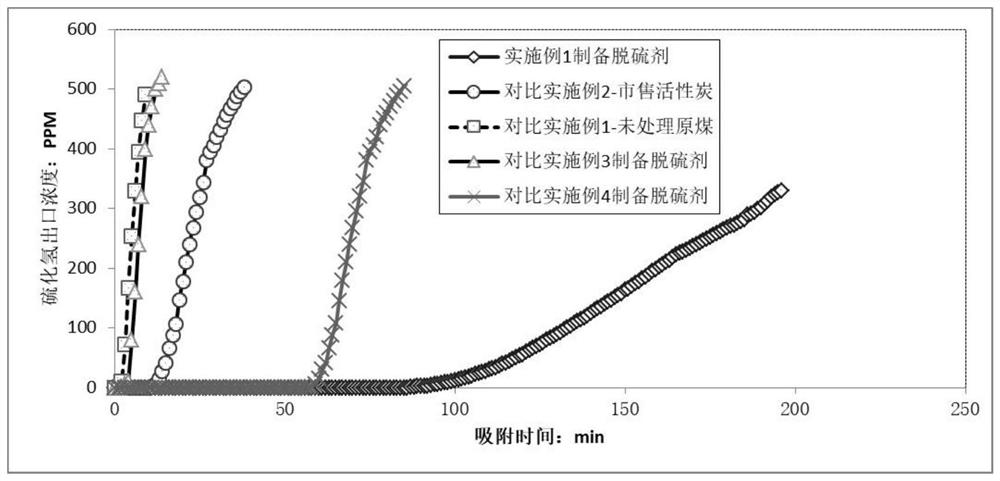

[0027] The hydrogen sulfide adsorption performance test of the desulfurizer in this example was carried out at room temperature. The adsorption performance test was carried out in a flow-through quartz fixed-bed reactor w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com