Lithium silicon oxide particle, preparation method thereof, negative electrode material, pole piece and battery

A technology of lithium particles and silicon oxygen, applied in the fields of silicon oxide lithium particles and their preparation, anode materials, pole pieces and batteries, can solve the problems of limiting the improvement of battery energy density, low first coulomb efficiency, etc., to reduce battery polarization , Improve the rate performance, the effect of good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

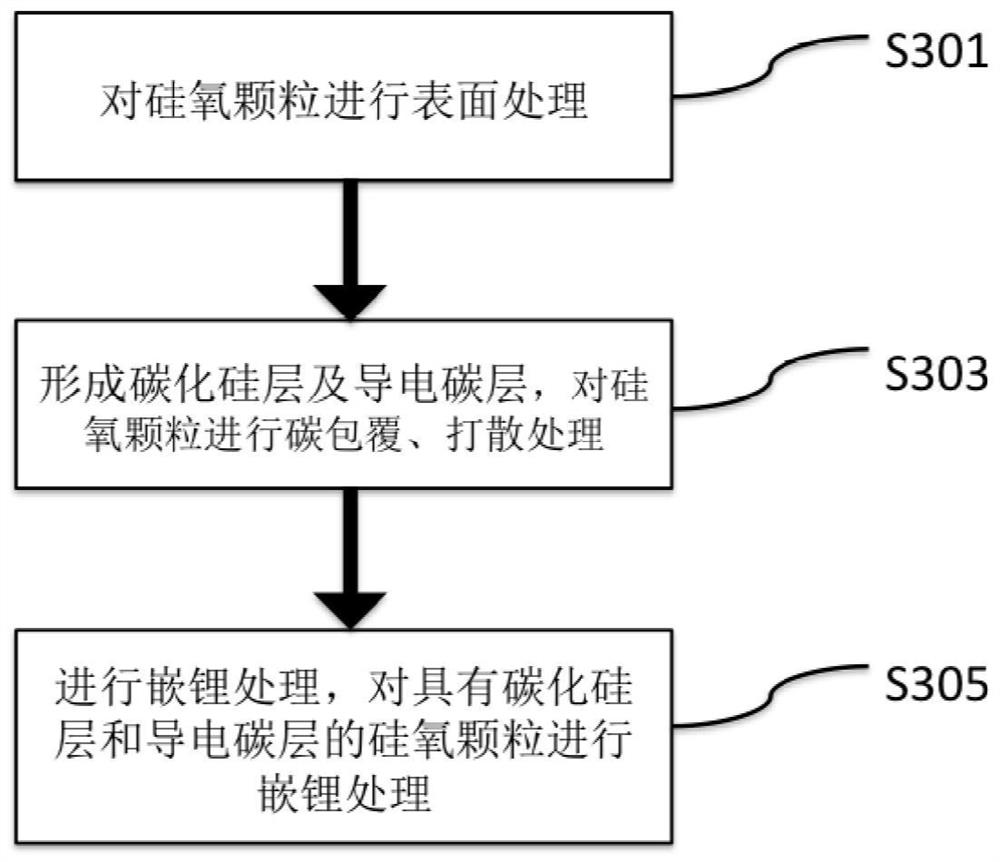

[0050] [Preparation method of silicon oxide lithium particles]

[0051] image 3 It is a flowchart of a method for preparing silicon oxide lithium particles according to an exemplary embodiment of the present application.

[0052] The specific process of preparing silicon oxide particles can be carried out by the following steps. First, the mixture of metal silicon powder and silicon dioxide powder is heated in the temperature range of 900° C. to 1600° C. in an inert gas atmosphere or under reduced pressure to generate silicon oxide gas. The gas will be deposited on the adsorption plate. When the temperature in the reaction furnace is lowered to below 100°C, the sediment is taken out, crushed and pulverized by equipment such as a ball mill, jet mill, etc., to obtain silicon oxide compound particles for future use.

[0053] see image 3 , in S301, performing surface treatment on the silicon oxide particles. According to an exemplary embodiment, the surface treatment includ...

Embodiment 1

[0079] Take silicon oxide particle powder (D50=5μm, SPAN=1.3, y=1 in the general formula of SiOy) and place it in the air (25°C) with a relative humidity of about 100%, heat it to 600°C and keep it for 60 minutes for surface treatment, Silica particles with an oxygen-enriched shell are obtained.

[0080] Add 2 kg of the above-mentioned surface-treated silicon-oxygen particle powder and 120 g of petroleum pitch powder into the VC mixer, and mix for 30 minutes at a speed of 8 m / s at the maximum diameter of the stirring part, so that the two raw materials are mixed evenly.

[0081] The above mixture was put into a graphite crucible, placed in a box furnace, fed with nitrogen protective gas, heated to 1000°C at a rate of 3°C / min, kept for 4h, and then naturally cooled to room temperature to complete the heat treatment. In this step, the pitch is carbonized under high-temperature treatment in an oxygen-free atmosphere to obtain a conductive carbon layer, and at the same time, it wi...

Embodiment 2

[0089] Take silicon oxide particle powder (D50=5μm, SPAN=1.3, y=1 in SiOy general formula) and put it in 20wt% hydrogen peroxide at a temperature of 50°C, keep stirring for 4 hours, then cool to room temperature, filter and dry.

[0090] The same is true for the mixing and heat treatment of the surface-treated silicon-oxygen particle powder and the carbon precursor in the above-mentioned embodiments, and the composite material obtained after the heat treatment is dispersed into a fine powder.

[0091] In the same manner as in Example 1, the silicon-oxygen particle powder was subjected to liquid-phase lithium intercalation treatment. Finally, after sieving and demagnetization treatment, the final product that can be used as negative electrode material is obtained.

[0092] In the same way as the test method of the above example, the measured particle size D50 of lithium silicon oxide particles in Example 2 is 6.3 μm, SPAN=1.40, and the specific surface area is 3.1 m 2 / g, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com