Preparation method of super-hydrophobic magnesium alloy

A magnesium alloy and super-hydrophobic technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems such as restricted applications, poor stability, and harsh equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

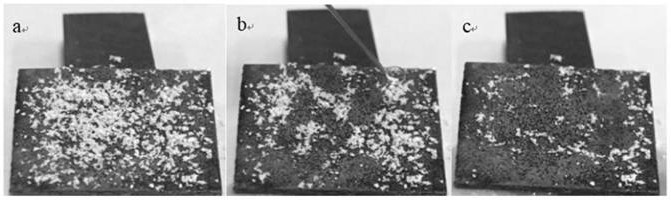

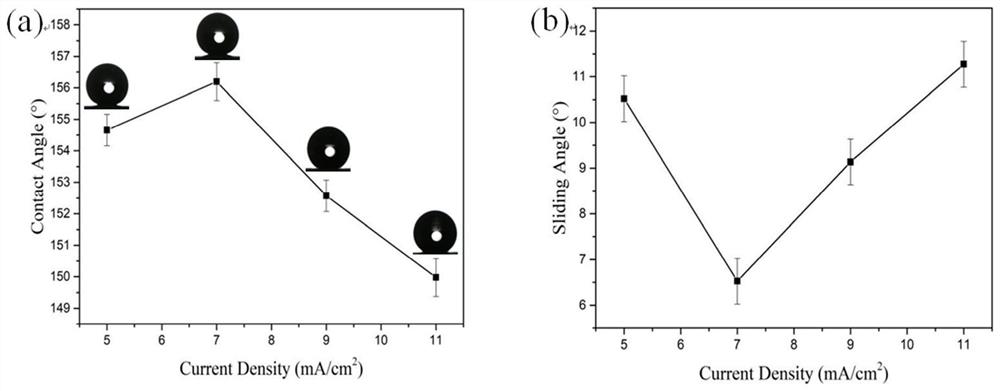

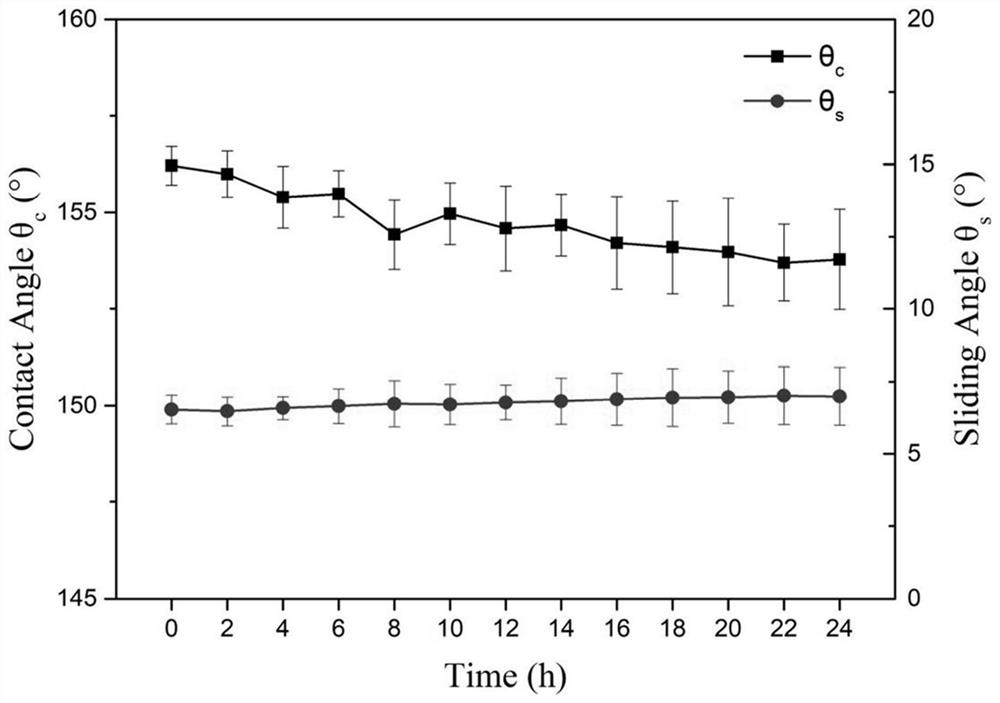

Image

Examples

Embodiment 1

[0037] A method for preparing a superhydrophobic magnesium alloy, comprising the steps of:

[0038] Step 1. Use a laser marking machine named Shanghai Bangyi Byes-30W to perform laser marking on the magnesium alloy substrate AZ31 that has undergone surface pretreatment to obtain a marked magnesium alloy substrate. The laser marking adopts a grid-type laser scanning method. The rated output power of laser scanning is 5W, the laser frequency is 20KHz, the laser wavelength is 1064nm, the spot diameter is 0.05mm, the scanning speed is 100mm / s, the distance between two adjacent scanning lines is 0.05mm, and the magnesium alloy substrate is marked AZ31 Has a convex-hull microstructure.

[0039] Specifically, the pretreatment method of the magnesium alloy original substrate AZ31 includes the following steps:

[0040] Step 1. Grinding the magnesium alloy substrate AZ31. Specifically, use 800# sandpaper, 1000# sandpaper, 1500# sandpaper and 2000# sandpaper to polish the surface of the...

Embodiment 2

[0049] A method for preparing a superhydrophobic magnesium alloy, comprising the steps of:

[0050] Step 1. Use a laser marking machine of Shanghai Bangyi Byes-30W to perform laser marking on the magnesium alloy substrate AZ31 that has undergone surface pretreatment to obtain a marked magnesium alloy substrate, so that the marked magnesium alloy substrate AZ31 has a convex hull shape micron Structure, laser marking adopts grid-type laser scanning method, the rated output power of laser scanning is 5W, the laser frequency is 20KHz, the laser wavelength is 1064nm, the spot diameter is 0.05mm, the scanning speed is 100mm / s, two adjacent scanning lines The spacing between them is 0.05mm.

[0051] Specifically, the pretreatment method of the magnesium alloy original substrate AZ31 includes the following steps:

[0052] Step 1. Grinding the magnesium alloy substrate AZ31. Specifically, use 800# sandpaper, 1000# sandpaper, 1500# sandpaper and 2000# sandpaper to polish the surface of...

Embodiment 3

[0061] A method for preparing a superhydrophobic magnesium alloy, comprising the steps of:

[0062] Step 1. Use a laser marking machine named Shanghai Bangyi Byes-30W to perform laser marking on the magnesium alloy substrate AZ31 that has undergone surface pretreatment to obtain a marked magnesium alloy substrate. The laser marking adopts a grid-type laser scanning method. The rated output power of laser scanning is 5W, the laser frequency is 20KHz, the laser wavelength is 1064nm, the spot diameter is 0.05mm, the scanning speed is 100mm / s, the distance between two adjacent scanning lines is 0.05mm, and the magnesium alloy substrate is marked AZ31 Has a convex-hull microstructure.

[0063] Specifically, the pretreatment method of the magnesium alloy original substrate AZ31 includes the following steps:

[0064] Step 1. Grinding the magnesium alloy substrate AZ31, specifically, use 800# sandpaper, 1000# sandpaper, 1500# sandpaper and 2000# sandpaper to polish the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com