Large-particle desorption agent for treating cadmium-contaminated soil as well as preparation and application methods

A technology for cadmium-contaminated soil and a desorbent, which is applied in the field of cadmium pollution and can solve problems such as secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

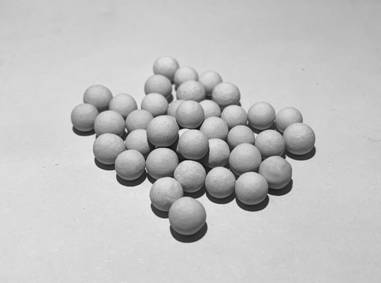

Image

Examples

Embodiment 1

[0038] (1). 2.5Kg organic sulfide sodium dimethyl dithiocarbamate and 4Kg lime, 2.5Kg zeolite powder, and 8Kg straw powder are added to the agglomerator, and the polyacrylamide glue aggregate is sprayed. The mass concentration of the polyacrylamide glue 18% to obtain spherical particles with a diameter of 5-10mm;

[0039] (2). Pass 2000g of Portland cement, 100g of silica powder, and 500g of waste glass powder through a vortex airflow pulverizer, refine and compound them under the impact of airflow, and obtain a coating agent;

[0040] (3). The coating agent obtained in step (2) and water are prepared into a slurry at a mass ratio of 1:3, and the surface of the spherical particles obtained in step (1) is sprayed and coated, and the spraying amount is 15% of the mass of the spherical particles. %, vibrated and dried on a vibrating sieve at 75°C to obtain a large particle desorbent for treating cadmium-contaminated soil.

Embodiment 2

[0042] (1). 2.5Kg organic sulfide sodium dimethyl dithiocarbamate and 3Kg lime, 2.5Kg zeolite powder, and 8Kg straw powder are added to the agglomerator, and the polyacrylamide glue aggregate is sprayed. The mass concentration of the polyacrylamide glue 18% to obtain spherical particles with a diameter of 5-10mm;

[0043] (2). Pass 2000g of Portland cement, 100g of silica powder, and 500g of waste glass powder through a vortex airflow pulverizer, refine and compound them under the impact of airflow, and obtain a coating agent;

[0044] (3). The coating agent obtained in step (2) and water are prepared into a slurry at a mass ratio of 1:3, and the surface of the spherical particles obtained in step (1) is sprayed and coated. The amount of spray coating is 12% of the mass of the spherical particles. %, vibrated and dried on a vibrating sieve at 75°C to obtain a large particle desorbent for treating cadmium-contaminated soil.

Embodiment 3

[0046] (1). 2Kg organic sulfide sodium dimethyl dithiocarbamate and 4Kg lime, 2Kg zeolite powder, and 8Kg straw powder are added to the agglomerator, and the polyacrylamide glue aggregate is sprayed. The mass concentration of the polyacrylamide glue is 18 %, to obtain spherical particles with a diameter of 5-10 mm;

[0047] (2). Pass 2000g of Portland cement, 160g of silica powder, and 500g of waste glass powder through a vortex airflow pulverizer, refine and compound them under the impact of airflow, and obtain a coating agent;

[0048] (3). The coating agent obtained in step (2) and water are prepared into a slurry at a mass ratio of 1:3, and the surface of the spherical particles obtained in step (1) is sprayed and coated, and the spraying amount is 10% of the mass of the spherical particles. %, vibrated and dried on a vibrating sieve at 75°C to obtain a large particle desorbent for treating cadmium-contaminated soil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com