Preparation method of low-thermal-resistance gallium nitride high-electron-mobility transistor epitaxial material

A technology of high electron mobility and epitaxial materials, which is applied in the field of epitaxial material preparation of GaN high electron mobility transistors with low thermal resistance, can solve the performance deterioration of device output power density and efficiency, lattice mismatch, increase aluminum nitride Thermal resistance and other issues, to achieve stable and controllable high-temperature etching technology, avoid material performance differences, and reduce the effect of interface thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

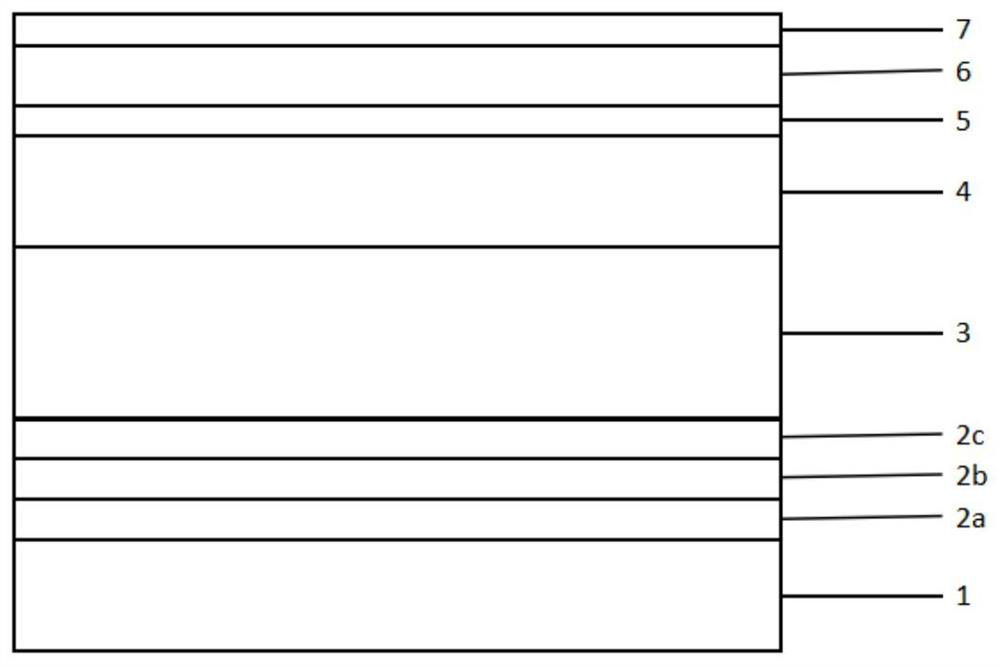

[0030] Step 1: Select a silicon carbide single crystal substrate and place it on the base in the reaction chamber of the high temperature chemical vapor deposition equipment;

[0031] Step 2: Set the pressure of the reaction chamber to 100~200 mbar, and inject H 2 , the temperature of the reaction chamber is raised to 1000~1100°C, under H 2 Bake the substrate under atmosphere for 5-15 minutes to remove surface contamination;

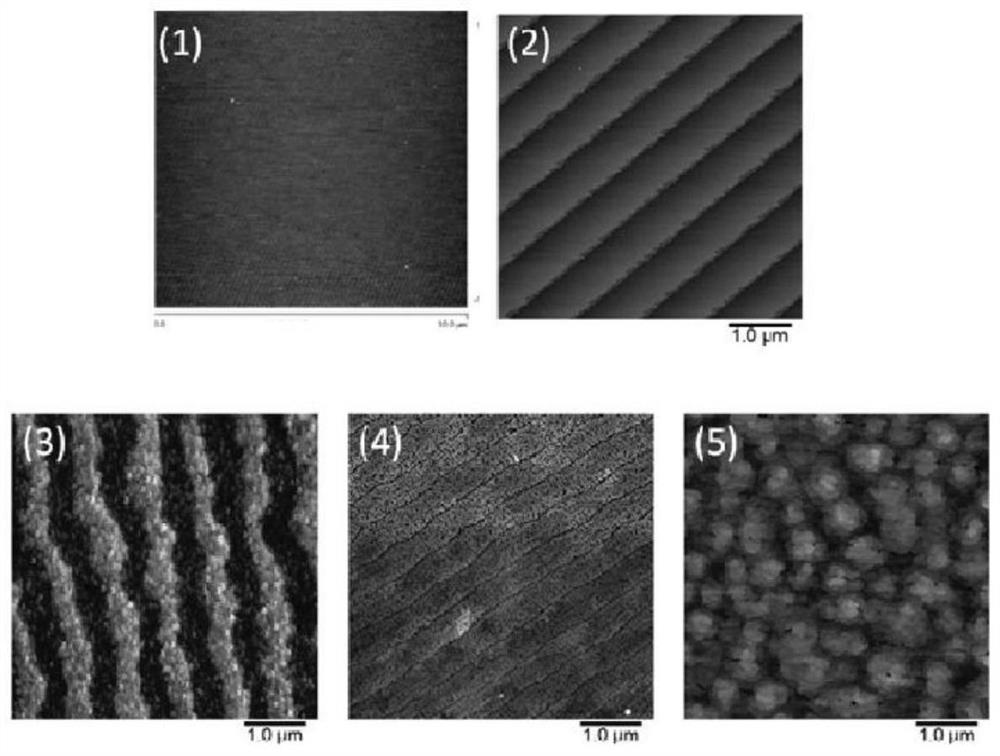

[0032] Step 3: Maintain H 2 The flow rate and the pressure of the reaction chamber remain unchanged, and the temperature of the reaction chamber is raised to 1300~1600°C. 2 Etch the substrate for 5-15 minutes under the atmosphere, so that the surface of the substrate presents an atomic step morphology;

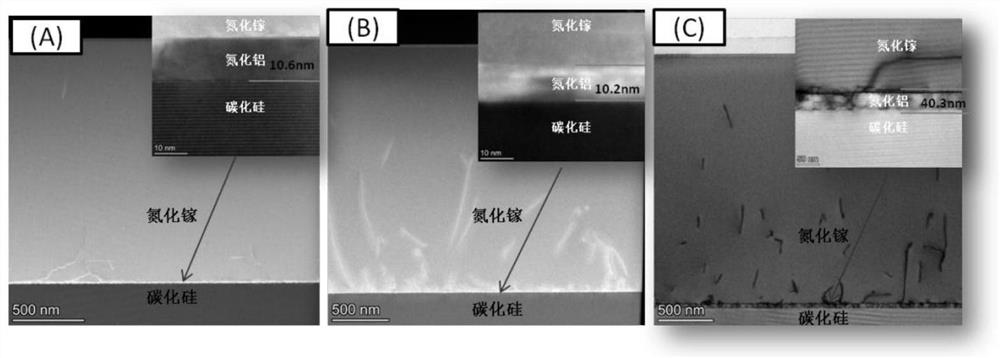

[0033] Step 4: Maintain H 2 The flow rate is constant, the pressure of the reaction chamber is set at 50~150 mbar, the temperature of the reaction chamber is set at 1100~1150°C, and NH 3 and an aluminum source to grow an aluminum nitride atomic depo...

Embodiment

[0046] Provided in a CVD (Chemical Vapor Deposition) system and an MOCVD (Metal Organic Compound Vapor Deposition) system is an epitaxial method for reducing the interface thermal resistance of GaN high electron mobility transistors, including the following steps:

[0047] Step 1: Select a 4-inch silicon carbide single crystal substrate and place it on the base in the CVD equipment.

[0048] Step 2: Set the reaction chamber pressure to 100mbar, H 2 With a flow rate of 100 slm, the temperature of the system was raised to 1080°C and held for 5 minutes to perform high-temperature cleaning on the substrate surface.

[0049] Step 3: Maintain the reaction chamber pressure and H 2 The flow rate remains unchanged, and the temperature continues to rise to 1500°C. 2 The substrate was etched for 10 minutes under the atmosphere, so that the surface of the substrate showed atomic step morphology.

[0050] Step 4: After the etching is completed, in the H 2 The temperature is lowered in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com