Porous moisture-permeable warm-keeping antistatic polyester fiber and preparation method thereof

A polyester fiber and antistatic technology, applied in the field of porous moisture-permeable thermal insulation antistatic polyester fiber and its preparation, can solve the problems of affecting hollowness, uneven cooling of strands, and difficulty in maintaining antistatic, and achieve stable operation. , Good uniformity and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

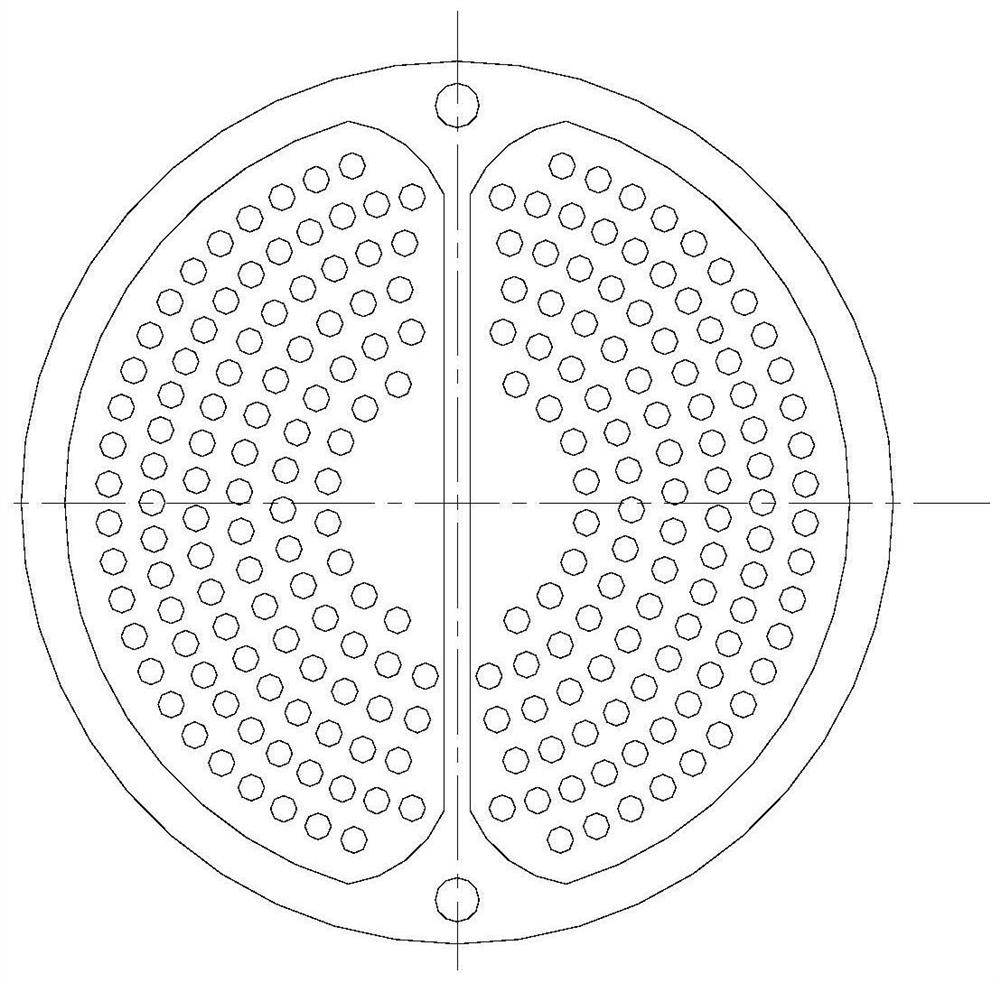

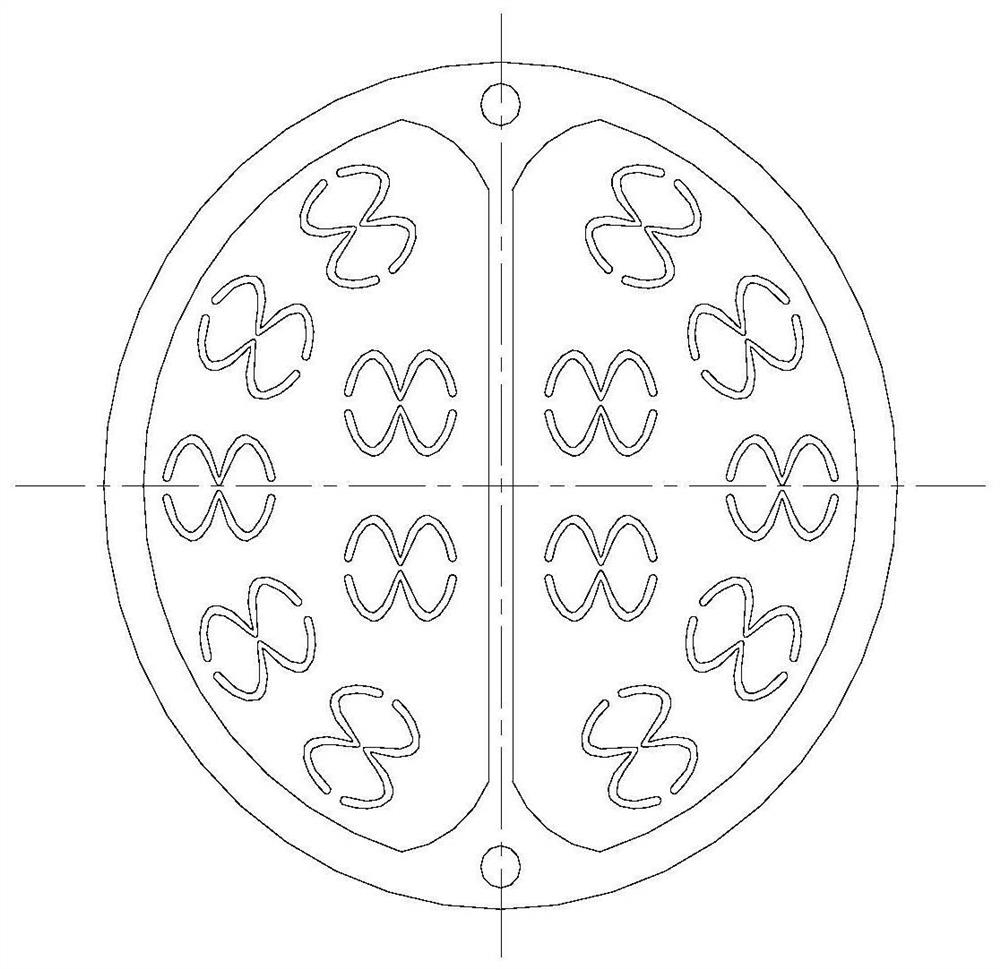

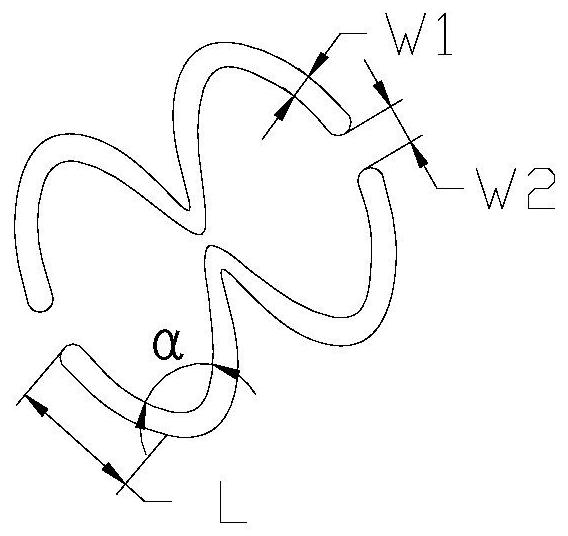

Method used

Image

Examples

Embodiment 1

[0066] A preparation method of porous moisture-permeable warm antistatic polyester fiber, the specific process is: antistatic modified polyester melt is transported to the spinning box → melt metering pump metering → spinning DIO component filtration → spinning Hole extrusion→cooling→oiling guide wire→winding and forming; the preparation steps of antistatic modified polyester are as follows:

[0067] (1) prepare antistatic slurry;

[0068] After mixing the antistatic agent (nano-scale zinc oxide powder) and ethylene glycol at a mass ratio of 1:20, first grind for 30 minutes, and then stir for 8 hours to obtain an antistatic slurry;

[0069] (2) preparing ethylene terephthalate slurry;

[0070] After mixing purified terephthalic acid and ethylene glycol at a molar ratio of 1:1.2, stir and mix at 85°C for 2 hours to prepare ethylene terephthalate slurry;

[0071] The addition of antistatic agent in the step (1) is 0.25wt% of the addition of purified terephthalic acid in the st...

Embodiment 2

[0112] A preparation method of porous moisture-permeable warm antistatic polyester fiber, the specific process is: antistatic modified polyester melt is transported to the spinning box → melt metering pump metering → spinning DIO component filtration → spinning Hole extrusion→cooling→oiling guide wire→winding and forming; the preparation steps of antistatic modified polyester are as follows:

[0113] (1) prepare antistatic slurry;

[0114] After mixing the antistatic agent (nano-scale zinc oxide powder) and ethylene glycol at a mass ratio of 1:25, first grind for 50 minutes, and then stir for 9 hours to obtain an antistatic slurry;

[0115] (2) preparing ethylene terephthalate slurry;

[0116] After mixing purified terephthalic acid and ethylene glycol at a molar ratio of 1:1.5, stir and mix at 95°C for 2 hours to prepare ethylene terephthalate slurry;

[0117] The addition of antistatic agent in step (1) is 0.35wt% of the addition of purified terephthalic acid in step (2); ...

Embodiment 3

[0128] A method for preparing porous, moisture-permeable, warm-keeping and antistatic polyester fiber. The specific process is as follows: the antistatic modified polyester melt is transported to the spinning box → the melt is metered by a metering pump → the spinning DIO component is filtered → spinning Hole extrusion→cooling→oiling guide wire→winding and forming; the preparation steps of antistatic modified polyester are as follows:

[0129] (1) prepare antistatic slurry;

[0130] After mixing the antistatic agent (nano-scale zinc oxide powder) and ethylene glycol at a mass ratio of 1:30, first grind for 60 minutes, and then stir for 10 hours to obtain an antistatic slurry;

[0131] (2) preparing ethylene terephthalate slurry;

[0132]After mixing purified terephthalic acid and ethylene glycol at a molar ratio of 1:2, stir and mix at 110°C for 2 hours to prepare ethylene terephthalate slurry;

[0133] The addition of antistatic agent in step (1) is 0.45wt% of the addition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com