Preparation method of hydroxyapatite/drug-loaded hydrogel composite coating on surface of micro-arc titanium oxide

A technology of hydroxyapatite and composite coating, which is applied in the direction of surface reaction electrolytic coating, coating, superimposed layer plating, etc. The problems of regionalized loading and poor bioactivity of the implant surface can achieve the effects of good apatite induction ability, good plasticity and toughness, and controllable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

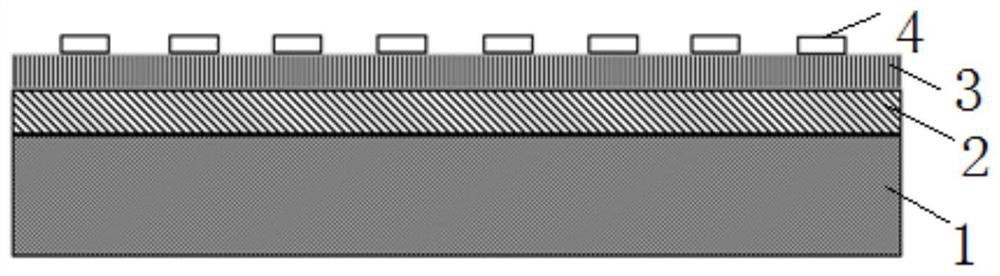

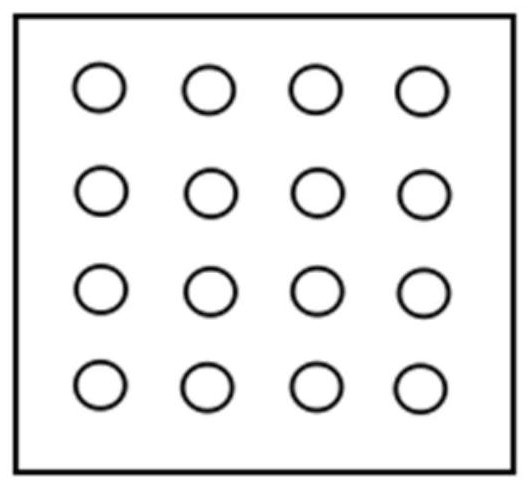

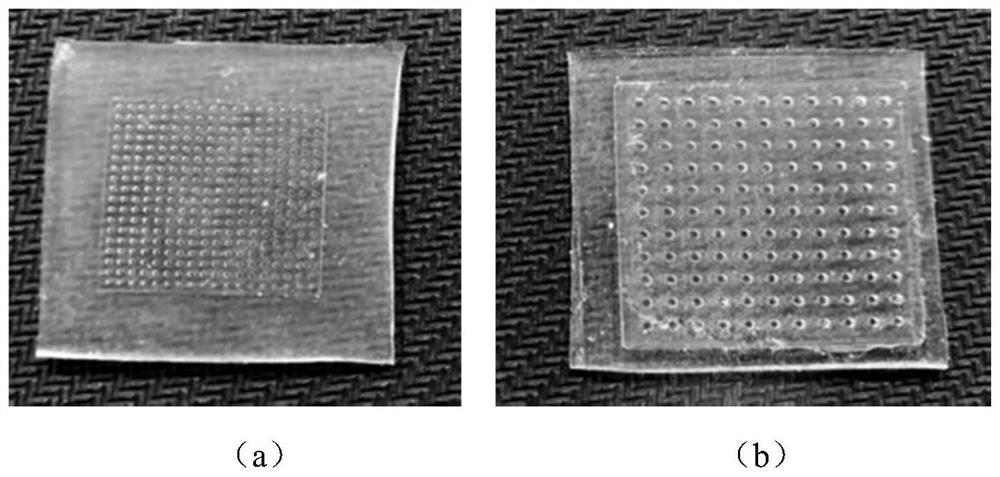

[0032] The preparation method of a kind of micro-arc oxidation titanium surface hydroxyapatite / medicine-loaded hydrogel composite coating of the present invention comprises the following steps:

[0033] 1) Dissolve one or more of lithium salts, calcium salts, tin salts, magnesium salts, potassium salts and sodium salts in water to form an electrolyte, use the titanium sample as the anode, and use the stainless steel tank as the cathode. The sample is immersed in the electrolyte for micro-arc oxidation, and a micro-arc oxidation coating is formed on the surface of the titanium sample; among them, the lithium salt is lithium phosphate, lithium silicate or lithium sulfate, and the calcium salt is calcium phosphate, calcium dihydrogen phosphate, Calcium silicate or calcium sulfate, tin salt as tin silicate, stannous sulfate or stannous pyrophosphate, magnesium salt as magnesium silicate, magnesium sulfate or magnesium phosphate, potassium salt as potassium silicate, potassium dihyd...

Embodiment 1

[0052] 1) Micro-arc oxidation treatment: Disodium EDTA, Ca(H 2 PO 4 ) 2 and NaOH are dissolved in water to form an electrolyte, the concentration of disodium EDTA in the electrolyte is 15g / L, Ca(H 2 PO 4 ) 2 The concentration of NaOH is 12g / L, and the concentration of NaOH is 5g / L. The titanium sample is used as the anode, the stainless steel tank is used as the cathode, and the electrolyte is added to the stainless steel tank, and the titanium sample is immersed in the electrolyte at 30°C for micro-arc oxidation. The parameters of the micro-arc oxidation are as follows: pulse voltage is used for oxidation, The positive pressure is 250V, the negative pressure is 80V, the micro-arc oxidation pulse frequency is 400Hz, the duty cycle is 10%, and the micro-arc oxidation time is 5mim. A micro-arc oxidation coating on the titanium surface was obtained. Among them, the titanium sample is TA2 industrial pure titanium.

[0053] 2) Hydrothermal treatment: adding NaOH to water to ...

Embodiment 2

[0062] 1) Micro-arc oxidation treatment: dissolve lithium phosphate, calcium sulfate and NaOH in water to form an electrolyte, the concentration of lithium phosphate in the electrolyte is 10g / L, the concentration of calcium sulfate is 15g / L, and the concentration of NaOH is 5g / L . The titanium sample is used as the anode, the stainless steel tank is used as the cathode, and the electrolyte is added to the stainless steel tank, and the titanium sample is immersed in the electrolyte at 20°C for micro-arc oxidation. The parameters of the micro-arc oxidation are as follows: pulse voltage is used for oxidation, The positive pressure is 500V, the negative pressure is 80V, the micro-arc oxidation pulse frequency is 500Hz, the duty cycle is 20%, and the micro-arc oxidation time is 7min. A micro-arc oxidation coating on the titanium surface was obtained. Among them, the titanium sample is TA3 industrial pure titanium.

[0063] 2) Hydrothermal treatment: adding NaOH to water to form a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com