A rapid composite casting method of aerospace high-strength aluminum alloy

A composite casting, high-strength technology, applied in the field of aluminum alloy casting, can solve the problems of high-strength aluminum alloy castings prone to body cracks, and achieve the effect of meeting the requirements of rapid production, reducing the tendency of cracking, and shortening the casting cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

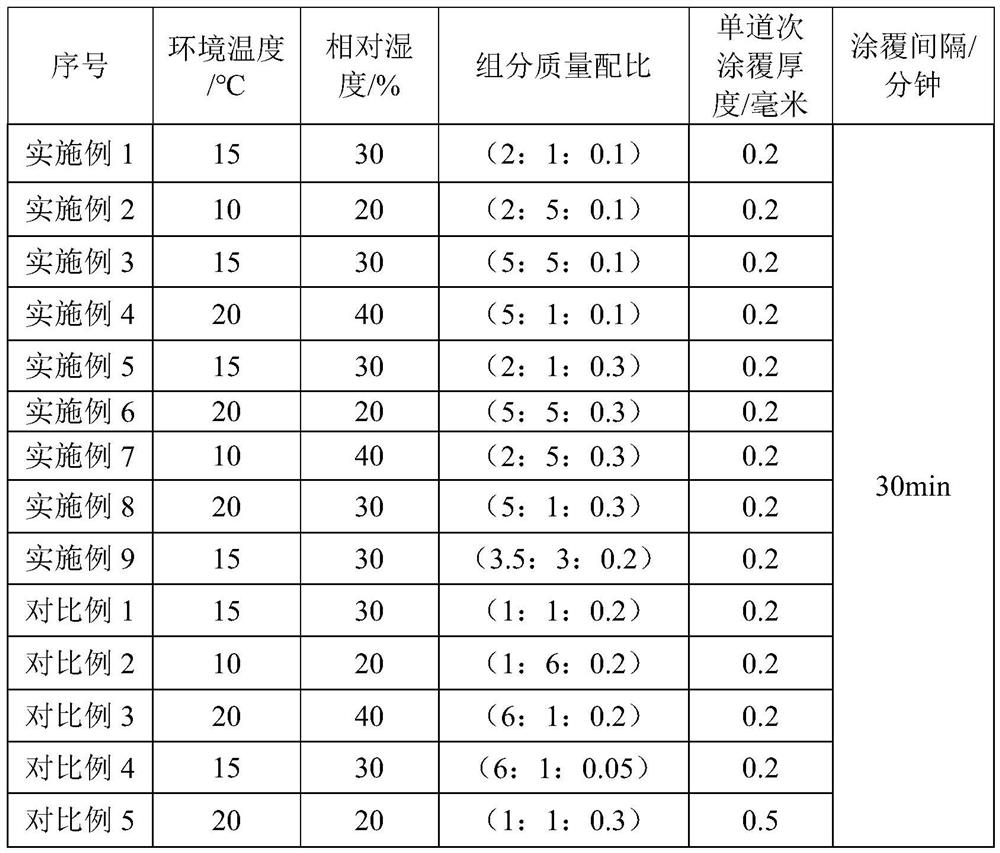

Embodiment 1

[0058] The present embodiment provides a rapid composite casting method for aerospace high-strength aluminum alloy, the steps comprising:

[0059]Step 1: Use 3D printing technology to quickly prepare two sets of sand molds inside and outside according to the shape of the workpiece and the casting process design plan; Step 2: Select appropriate materials to prepare the transition layer; Step 3: Use automatic coating equipment to coat the 3D printed sand mold Step 4: Assemble the sand mold and perform high-strength aluminum alloy casting to complete the casting of the high-strength aluminum alloy casting.

[0060] For the preparation of the transition layer in step 2, the transition layer includes refractory A component, adhesive B component and defoamer component C, the refractory is quartz sand, the adhesive is silica sol, and the defoamer is n-Octanol. Among them, the mass ratio of A component, B component and defoamer is 2:1:0.1.

[0061] The preparation method of the tran...

Embodiment 2

[0068] This embodiment provides another method for rapid composite casting of aerospace high-strength aluminum alloys. The other steps are the same as those in Embodiment 1, and will not be repeated here. , the transition layer includes refractory A component, adhesive B component and defoamer component C, the refractory is quartz sand, the adhesive is silica sol, and the defoaming agent is n-octanol. Among them, the mass ratio of A component, B component and defoamer is 2:5:0.1.

[0069] In step 3, use automatic coating equipment to coat the surface of the test piece with the coating material for many times to obtain the desired transition layer.

[0070] Step 301 : using an automatic coating process to coat the surface of the test piece with a transition layer coating material to obtain a first coating; the ambient temperature during coating is 10° C. and the relative humidity is 20%.

[0071] In this embodiment, the strength of the transition layer obtained by the above co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com