Hard carbon negative electrode material, lithium ion battery as well as preparation method and application of hard carbon negative electrode material

A negative electrode material, hard carbon technology, applied in the direction of carbon preparation/purification, negative electrode, battery electrode, etc., can solve the problems of low reversible capacity and low initial Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

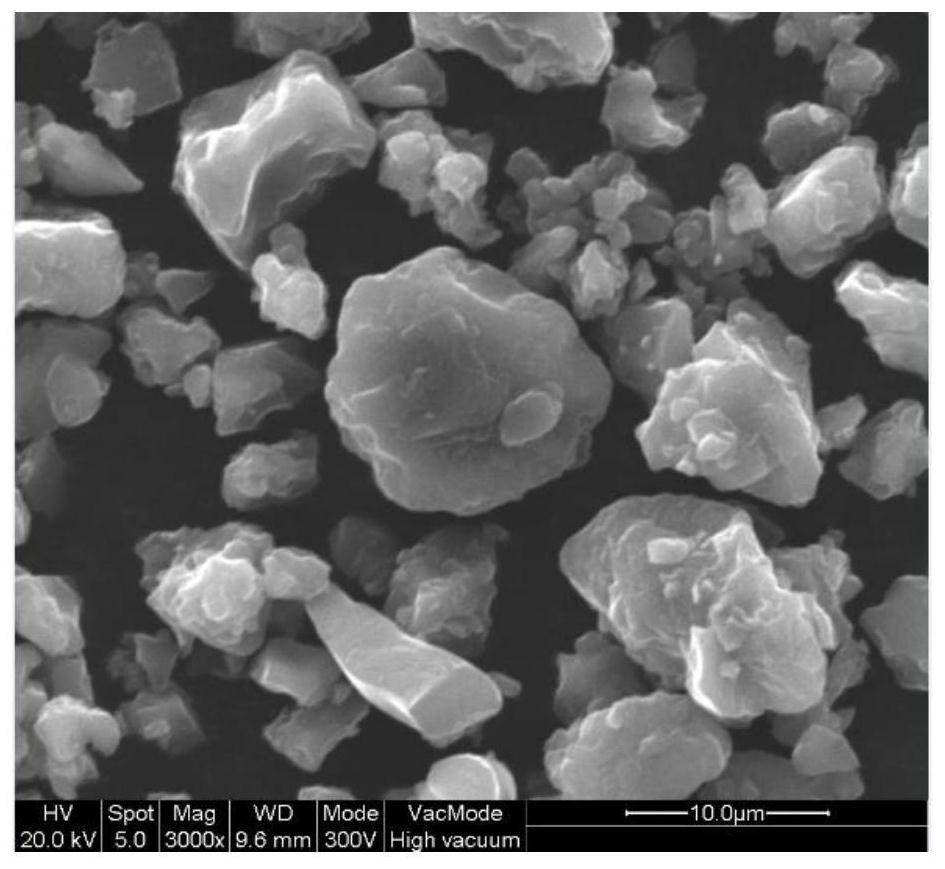

Image

Examples

Embodiment 1

[0087] In step (1), the petroleum asphalt with a softening point of 250° C. is made into a median particle size D by using a jet mill classifier. 50 It is a carbon source precursor powder of 5 μm; under the condition of stirring, the prepared carbon source precursor powder is dispersed in deionized water, and the mass ratio of the carbon source precursor powder to deionized water is 45:100, And mix according to the mass ratio of the carbon source precursor powder to 30% hydrogen peroxide, 20% nitric acid, boric acid, melamine, and Tween 20 in a ratio of 100:35:50:10:10:2 ; and then carry out the cross-linking reaction at 150° C. for 8 hours to obtain the modified carbon source precursor.

[0088] In step (2), the modified carbon source precursor is heat-treated under nitrogen protection, and the temperature is raised to 550°C at a heating rate of 3°C / min, and kept for 2h, and then lowered to room temperature after the heat treatment; the heat-treated material volatilizes The ...

Embodiment 2

[0091] In step (1), the petroleum asphalt with a softening point of 280° C. is made into a median particle size D by using a jet mill classifier. 50 It is a carbon source precursor powder of 5 μm; under the condition of stirring, the prepared carbon source precursor powder is dispersed in water, the mass ratio of carbon source precursor powder to water is 45:100, and according to the carbon source Mix the precursor powder with ammonium persulfate, 80% phosphoric acid, and cetyltrimethylammonium bromide in a mass ratio of 100:20:38:2; then carry out crosslinking reaction at 180°C for 4h , to prepare a modified carbon source precursor.

[0092] In step (2), the modified carbon source precursor is heat-treated under nitrogen protection, and the temperature is raised to 600°C at a heating rate of 3°C / min, and kept for 1h, and then lowered to room temperature after the heat treatment; the heat-treated material volatilizes The content of the component is 6%. Under the condition of...

Embodiment 3

[0095] In step (1), the coal tar pitch with a softening point of 250° C. is made into a median particle size D by using a jet mill classifier. 50 It is a carbon source precursor powder of 5 μm; under the condition of stirring, the prepared carbon source precursor powder is dispersed in water, the mass ratio of carbon source precursor powder to water is 45:100, and according to the carbon source The precursor powder is mixed with 30% hydrogen peroxide, performic acid, 80% phosphoric acid, urea, and Tween 20 in a mass ratio of 100:35:20:15:10:2; After 4 hours of joint reaction, the modified carbon source precursor was prepared.

[0096]In step (2), the modified carbon source precursor is heat-treated under nitrogen protection, and the temperature is raised to 600°C at a heating rate of 3°C / min, and kept for 1h, and then lowered to room temperature after the heat treatment; the heat-treated material volatilizes The content of the component is 6%. Under the condition of stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com