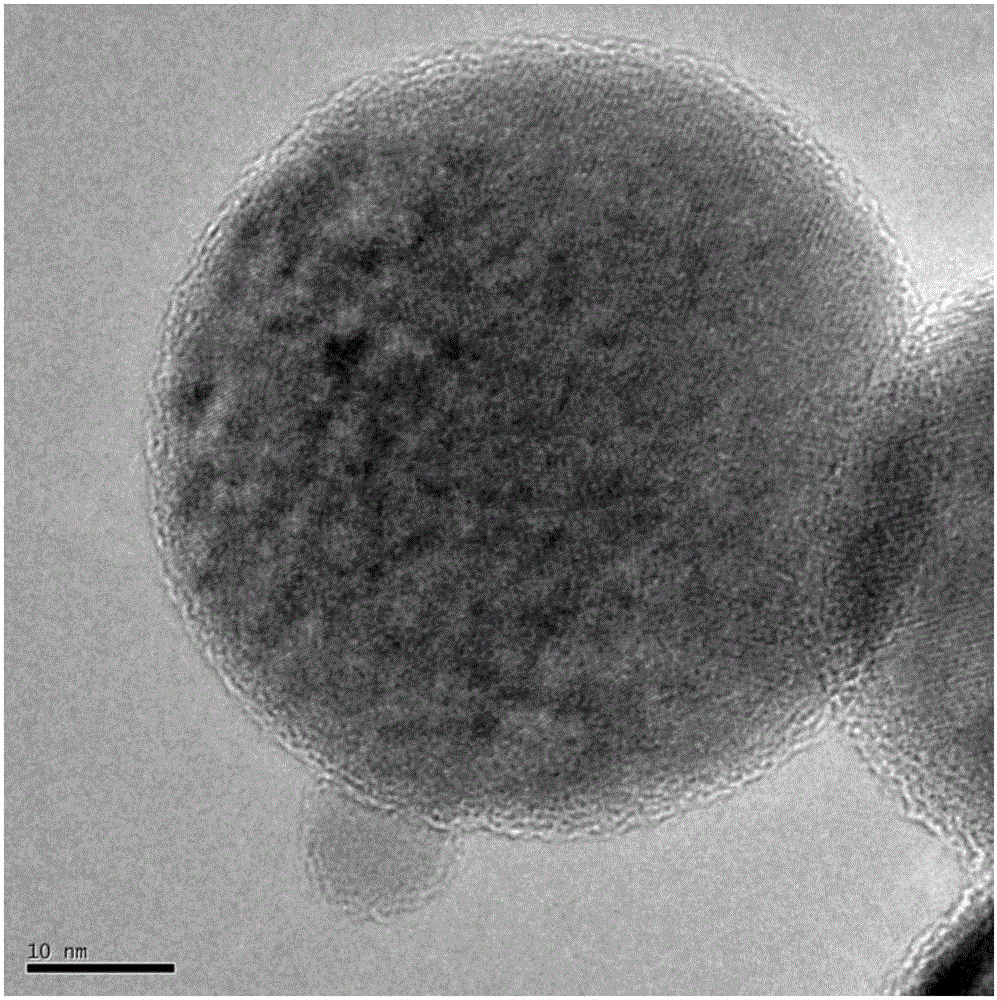

Graphene film-in-situ-coated lithium iron phosphate positive electrode material and preparation method therefor

A technology of lithium iron phosphate and cathode materials, which is applied in the field of composite materials, can solve the problems of uneven coating, agglomeration, and poor performance of coating materials, and achieve the effects of low cost, increased energy density, and inhibited growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1): Weigh ferrous sulfate heptahydrate (molecular formula FeSO 4 ·7H 2 (O) 41.7g, hexamethylenediamine tetramethylene phosphonic acid (molecular formula C 10 h 28 N 2 o 12 P 4 ) 18.5g, lithium hydroxide monohydrate (molecular formula LiOH·H 2 (0) 18.8g, dissolved in 500ml deionized water successively, magnetically stirred until a transparent solution A was formed, and set aside.

[0050] 2): Weigh 1.2 g of graphene oxide (1-2 layers) powder, and ultrasonically disperse it in 100 ml of deionized water at 20-45° C. to obtain dispersion solution B (pH 6-8).

[0051] 3): Mix solution A and dispersion solution B, and under the protection of argon, stir and disperse at high speed to obtain solution C.

[0052] 4): Quickly transfer solution C to a 1000ml stainless steel reactor, react at 185°C for 8 hours, wash with absolute ethanol and deionized water after cooling until no SO 4 2- , suction filtration, and vacuum drying at 70°C to obtain precursor powder.

[0053] ...

Embodiment 2

[0057] 1): Weigh respectively ferrous sulfate heptahydrate (molecular formula FeSO 4 ·7H 2 (O) 125.1g, two 1,6-hexamethylenetriaminepentamethylene phosphonic acid (molecular formula C 17 h 44 o 15 N 3 P 5 )61.7g, lithium hydroxide monohydrate (molecular formula LiOH·H 2 (0) 56.4g, dissolved in 1000ml deionized water successively, magnetically stirred until a transparent solution A was formed, and set aside.

[0058] 2): Weigh 2.84g of graphene oxide (3-5 layers) powder and ultrasonically disperse it in 300ml of deionized water at 20-45°C to obtain dispersion solution B (pH6-8).

[0059] 3): Mix the solution A and the dispersion solution B, under the protection of argon, mix evenly to obtain the solution C.

[0060] 4): Quickly transfer solution C to a 2000ml stainless steel reactor, react at 200°C for 6h, wash with absolute ethanol and deionized water after cooling until there is no SO 4 2- , suction filtration, and vacuum drying at 70°C to obtain precursor powder.

...

Embodiment 3

[0064] 1): Weigh respectively ferrous sulfate heptahydrate (molecular formula FeSO 4 ·7H 2 O) 83.4g, aminomethylphosphonic acid (molecular formula CH 6 NO 3 P) 33.3g, lithium hydroxide monohydrate (molecular formula LiOH·H 2 O) 37.6g, and dissolved in 700ml deionized water successively, magnetically stirred until forming transparent solution A, for subsequent use.

[0065] 2): Weigh 1.58g of graphene oxide (6-9 layers) powder and ultrasonically disperse it in 200ml of deionized water at 20-45°C to obtain dispersion solution B (pH6-8).

[0066] 3): Mix solution A and dispersion solution B, and under the protection of argon, uniformly disperse to obtain solution C.

[0067] 4): Quickly transfer solution C to a 1500ml stainless steel reaction kettle, react at 220°C for 5h, wash with absolute ethanol and deionized water after cooling until there is no SO 4 2- , suction filtration, and vacuum drying at 70°C to obtain precursor powder.

[0068] 5): Put the precursor powder in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Grain | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com