Preparation method of powder containing nano-antibacterial elements

A powder and element technology is applied in the field of preparation of nanometer antibacterial element powder, which can solve the problems of difficult process and high cost, and achieve the effects of simple process, low cost and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

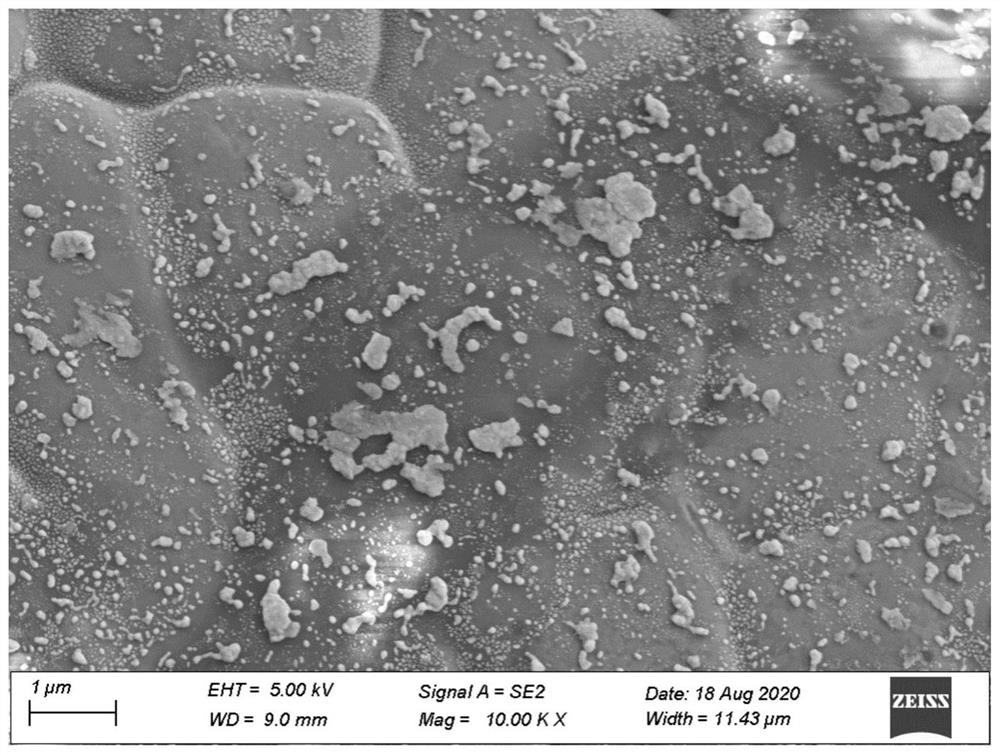

[0071] Nano-silver particles were deposited on stainless steel powder by magnetron sputtering to prepare nano-silver antibacterial stainless steel powder

[0072] 1) Target selection: choose a columnar silver magnetron sputtering target, and use intermediate frequency magnetron sputtering;

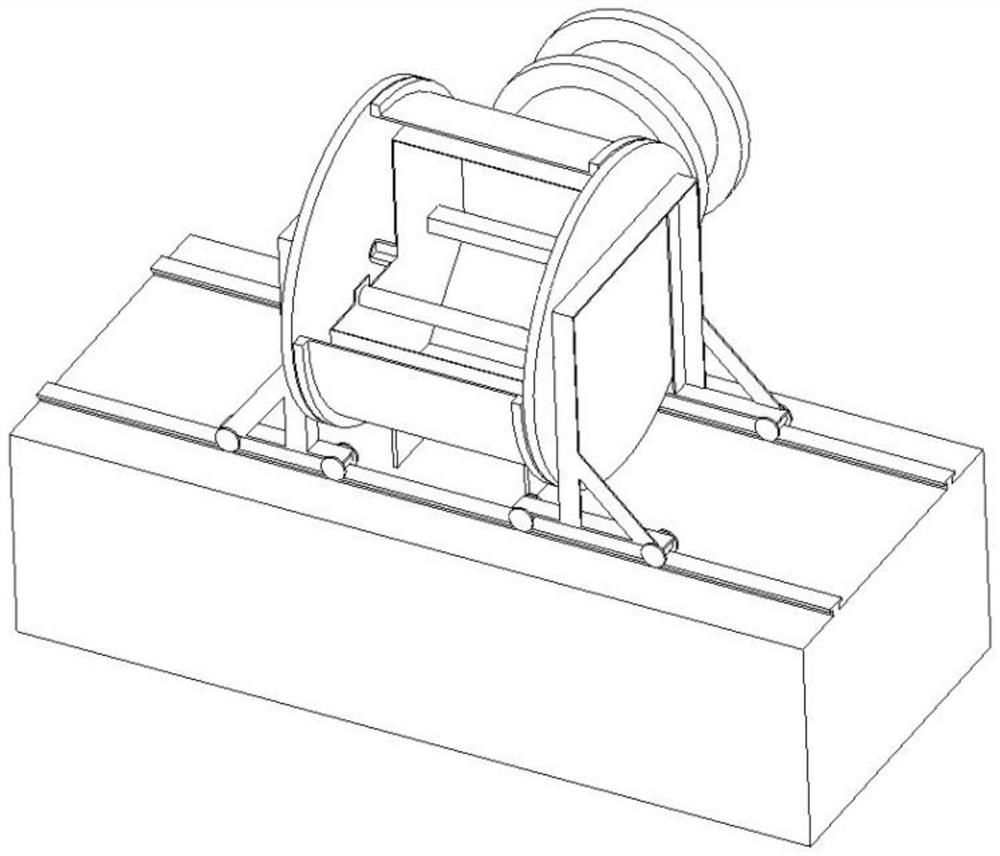

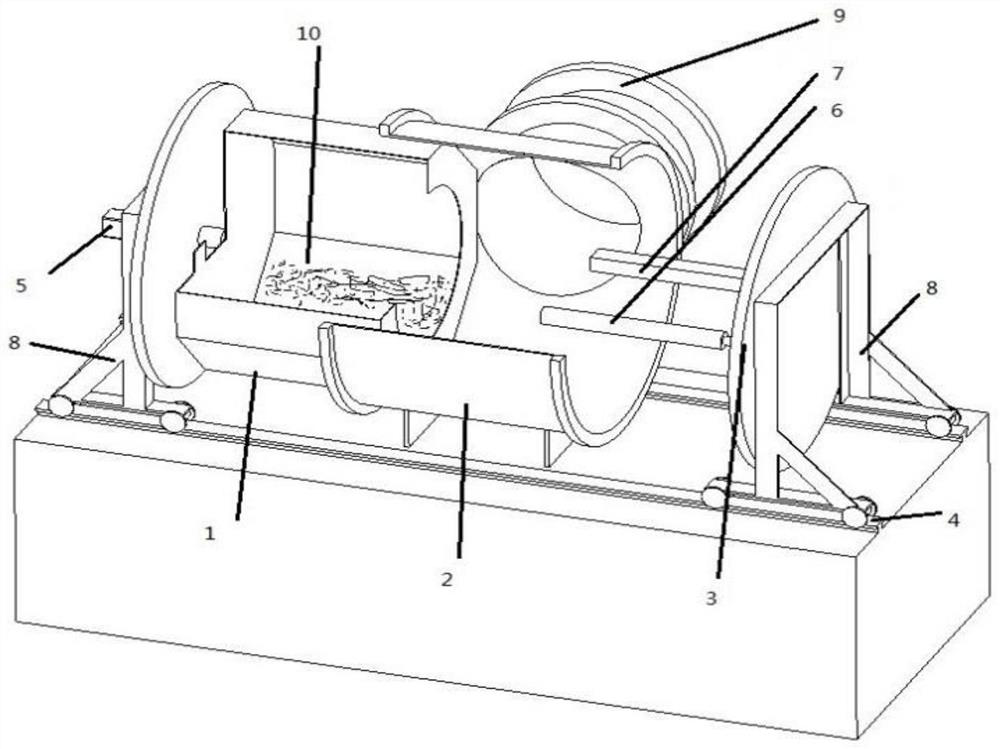

[0073] 2) Powder loading: Put 20 kg of stainless steel powder into the drum connected to the bias negative electrode, rotate the drum, and check the movement of the powder: no spillage, no sticking to the wall of the cylinder;

[0074] 3) Vacuuming and heating: close the furnace door, vacuuming is better than 6.6x10 -3 Pa, while vacuuming and heating, until 200 degrees Celsius, let the powder moisture desorb, improve fluidity, and not easy to agglomerate;

[0075] 4) Glow ion bombardment cleaning: vacuuming is better than 6.6x10 -3 Pa, fill with argon gas, up to 6Pa, apply bias voltage -600V, generate glow discharge, bias current 4A, ion bombardment for 15 minutes, purify the powder;

...

Embodiment 2

[0079] Nano silver particles were deposited on zirconium phosphate powder by magnetron sputtering to prepare nano silver antibacterial zirconium phosphate powder

[0080] 1) Target selection: choose a columnar silver magnetron sputtering target, and use intermediate frequency magnetron sputtering.

[0081] 2) Powder loading: Put 10 kg of zirconium phosphate powder into the drum connected to the bias negative electrode, rotate the drum, and check the movement of the powder: no spillage, no sticking to the wall of the drum.

[0082] 3) Vacuuming and heating: close the furnace door, vacuuming is better than 6.6x10 -3 Pa, while vacuuming and heating, up to 150 degrees Celsius, to desorb the moisture of the powder, improve the fluidity and prevent agglomeration.

[0083] 4) Glow ion bombardment cleaning: vacuuming is better than 6.6x10 -3 Pa, fill with argon gas, up to 6Pa, apply bias voltage -600V, generate glow discharge, bias current 2A, ion bombardment for 10 minutes, purify ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com