Sample preparation method for in-situ observation of dislocation slip traces by transmission electron microscope

A transmission electron microscope and sample preparation technology, which is applied in the preparation of test samples, material analysis and sampling using wave/particle radiation, etc. It can solve the inconvenience of analysis, difficulty in finding suitable samples, uncertain loading force of polycrystalline materials, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

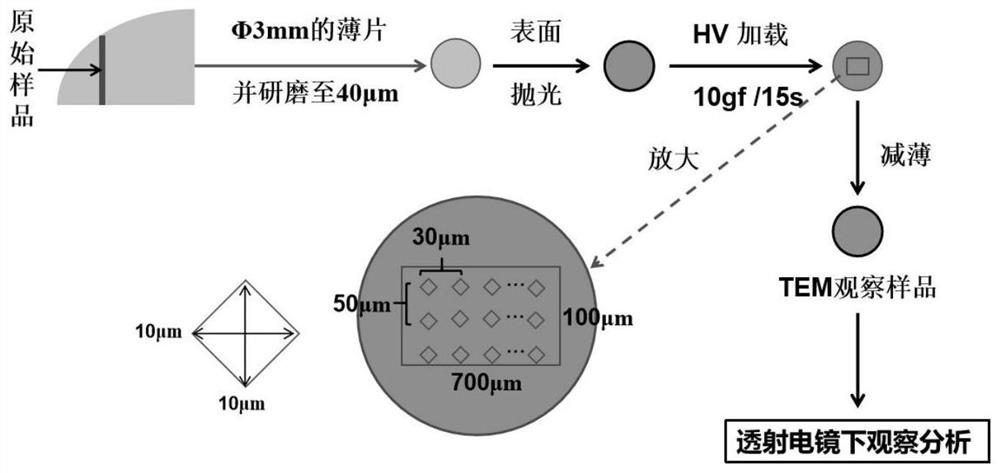

[0020] This embodiment provides a sample preparation method for in-situ observation of dislocation slip traces by a transmission electron microscope, such as figure 1 As shown, it mainly includes the following steps:

[0021] Step 1: Sample cutting and processing, the specific method is: first use wire cutting equipment to cut thin slice samples on the alloy material along the radial direction of the button ingot; then use 150#, 320#, 800# and 2000# sandpaper to grind the samples in turn , and thin it to 40 microns; finally, use a puncher to make a sample sheet with a diameter of 3mm suitable for transmission electron microscope observation.

[0022] Step 2: Surface polishing; use double spray equipment to remove the grinding marks and residual stress on the surface of the sample treated in step 1; among them, only need to remove the grinding scratches and slightly corrode the grain boundaries, and ensure that no small holes appear; The specific parameters of the double spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com