Hydraulic orienting device for horizontal well

A technology of directional device and hydraulic jet, which is applied in wellbore/well components, production fluid, earthwork drilling and other directions, can solve the problem of inability to guarantee the accurate position of rotation, and achieve the effect of high construction efficiency, simple structure and ingenious installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

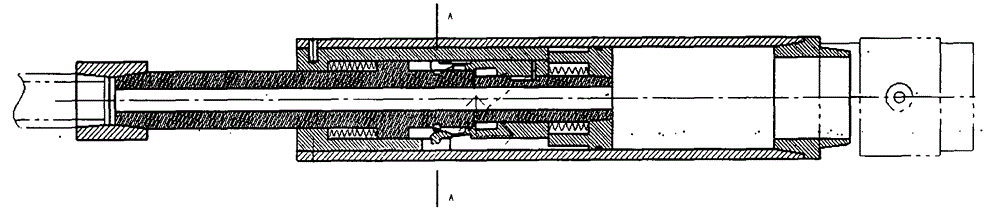

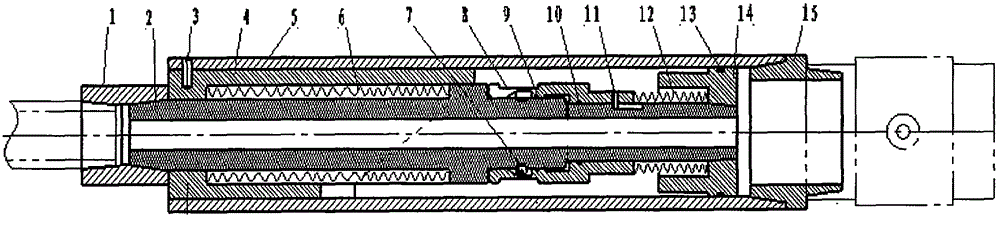

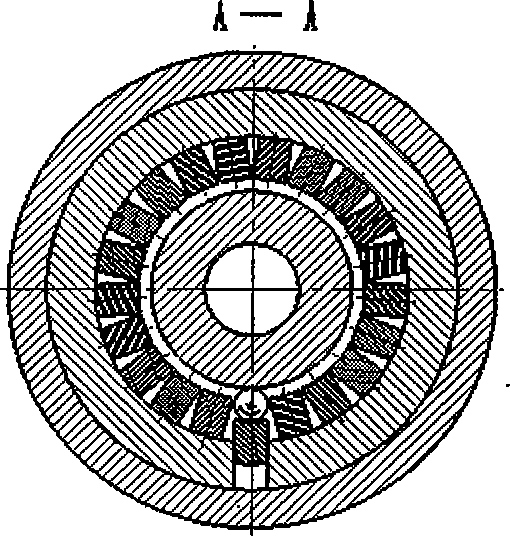

[0023] The interior of the horizontal well directional joint is composed of three units. They are core tube unit, shoe guide unit and orientation unit.

[0024] The core tube unit is mainly composed of the core tube 2 . Provides a channel for high pressure fluid flow. The core tube 2 has a groove at the lower end contact portion of the directional claw sleeve 8, and is connected by a directional screw 11, so that the directional claw sleeve can only move along the axis of the core tube 2. The inner diameter of the core pipe 2 is smaller than the lower joint 15, and there is a cavity between the lower joint 15 and the lower joint 15. When pumping high-pressure fluid into the well, due to the throttling effect of the nozzle, there will be high-pressure fluid in the cavity, and these high-pressure fluids will provide power for the forward and backward movement and rotation of the entire directional joint. There is an annular groove at the contact position between the core tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com