Device and method for testing anti-icing performance of asphalt mixture

A technology of asphalt mixture and testing device, which is used in measurement device, suspension and porous material analysis, scientific instrument, etc., can solve interlayer damage, affect the test accuracy of pull-out force and ice-breaking force, and is not suitable for evaluating mixtures Ice repellency and other problems, to achieve the effect of ingenious installation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The following examples illustrate the use of the asphalt mixture ice-phobic test device. What needs to be evaluated in this example is the ice-phobicity of open-graded porous asphalt mixture OGFC-13 and densely-graded asphalt mixture AC-13, see Table 1.

[0059]

[0060] 1. Double-sided compaction molding of Marshall specimens

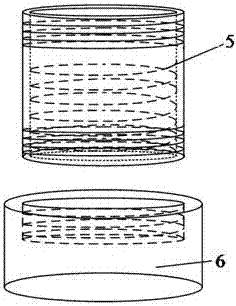

[0061] Assemble the sleeve 5 and the concave base 6 of the present invention, pour the OGFC-13 loose mixture mixed at high temperature, put it into a Marshall compaction instrument, and after compacting 50 times on one side, disassemble the sleeve After 5, replace it up and down and assemble it into the concave base 6 again, and compact it 50 times. After standing at room temperature for 12 hours, unscrew the sleeve containing the mixture sample from the base.

[0062] When forming AC-13, it only needs to change the above compaction 50 times to 75 compaction times.

[0063] 2. Water injection of test piece

[0064] Apply mechanical greas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com