An in-hole sensor base with controllable direction

A sensor base and sensor technology, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc., can solve the problems of uncontrollable sensor direction, influence of test results, poor coupling between sensor and hole wall, etc., and achieve simple structure , Reasonable design, and high azimuth accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but these embodiments should not be construed as limiting the present invention.

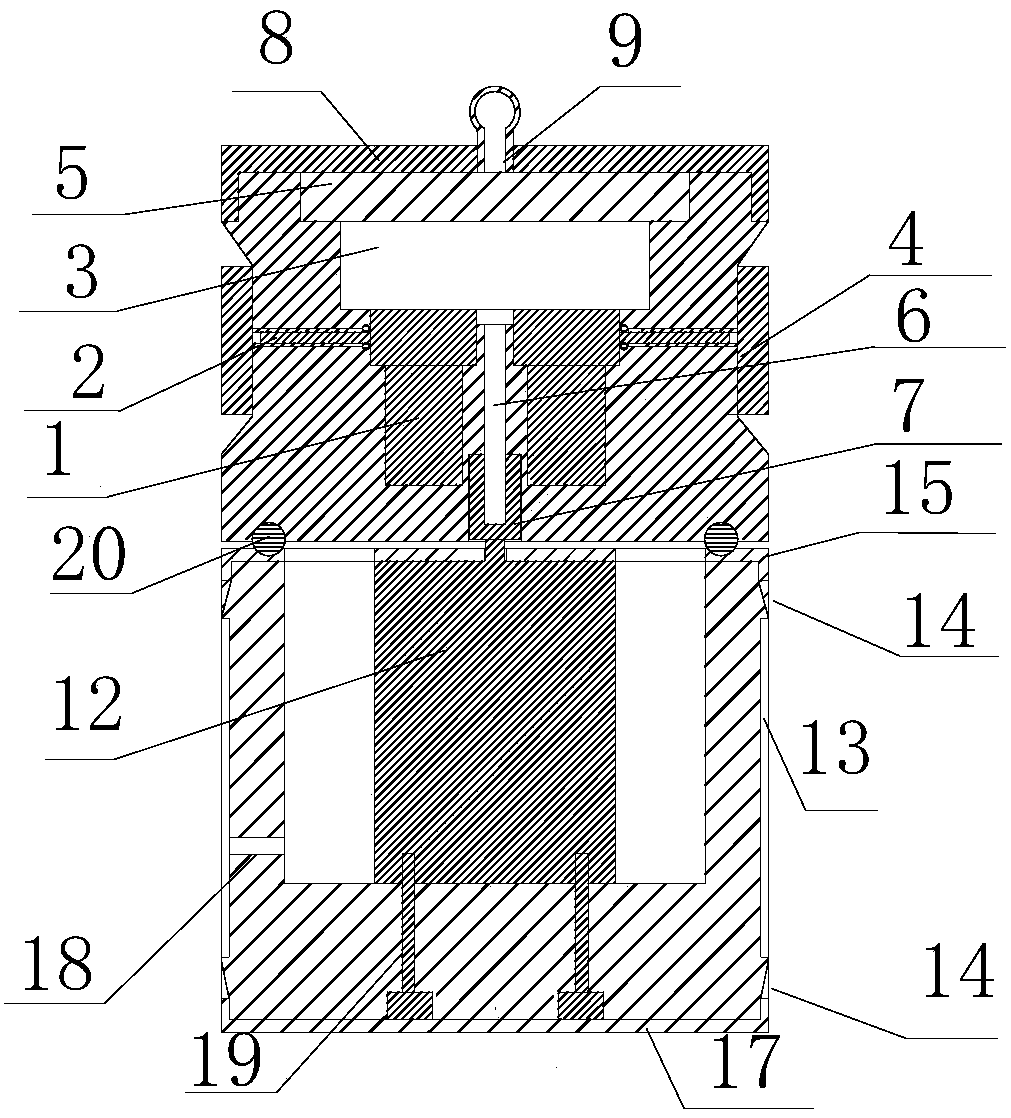

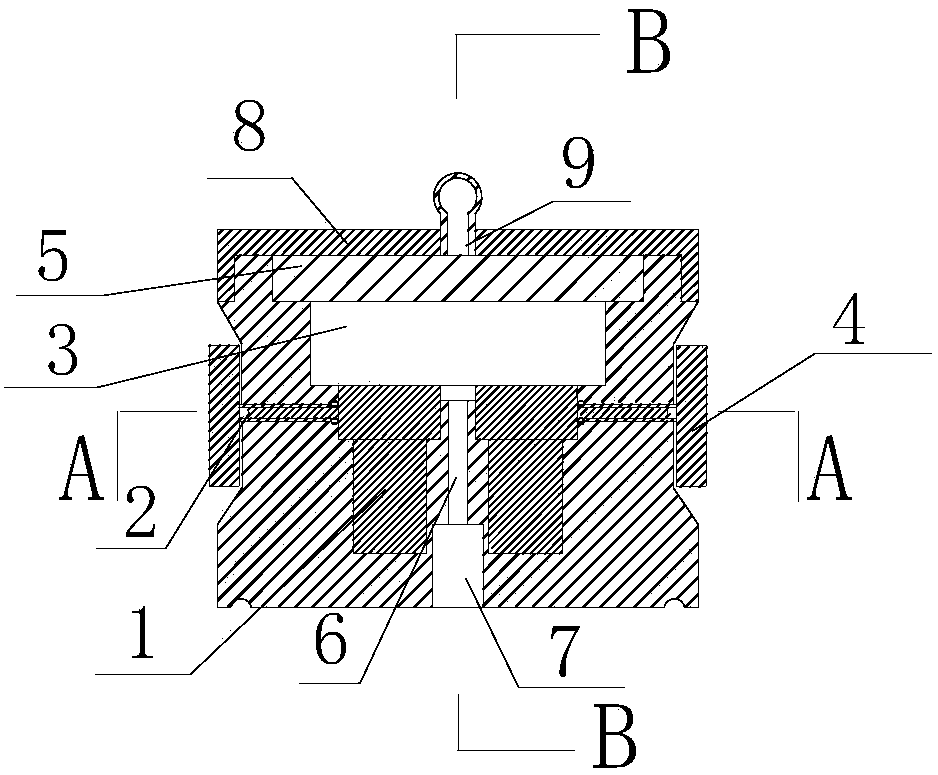

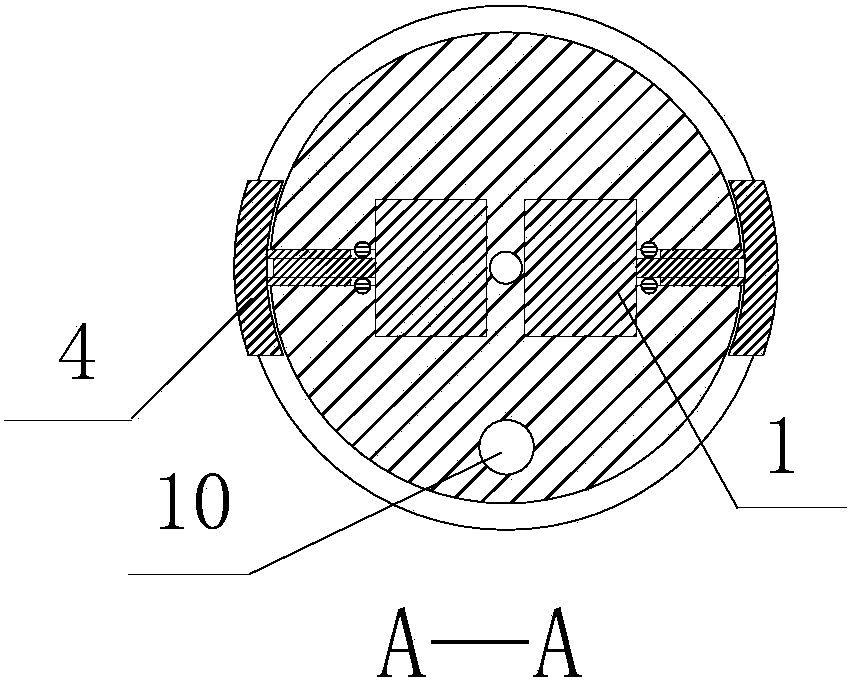

[0028] Such as Figure 2A , Figure 2B , Figure 2C and Figure 3A , Figure 3B , Figure 3C As shown, a direction-controllable in-hole sensor base includes an upper base and a lower base. As shown in Figure 2, the upper base includes a DC turbine worm motor 1 (ASLONG A58SW31ZY), a push rod 2, a sensor nest 3, a support shoe 4, an electronic compass 5 (DCM220B), a screw 6, an upper base cap 8, a lifting ring 9 and a limiter. Bit pile 11. The DC turbine worm motor 1 is fixed on the bottom of the upper base, the sensor nest 3 is fixed on the top of the DC turbine worm motor 1, the sensor is fixed inside the sensor nest 3, the electronic compass 5 is fixed on the top of the sensor nest 3, and the electronic compass 5 The X and Y directions are consist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com