Bi-component room temperature vulcanized silicone rubber composition for sensor and preparation method thereof

A silicone rubber composition, room temperature vulcanization technology, applied in the field of sealants, can solve the problems of easy gaps between the inner cavity side wall of the sensor shell and the sound-absorbing material, affecting the effect of aftershock elimination, and difficult to stir evenly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] 1. Preparation of modified sound-absorbing filler:

[0065] Heat 100 parts by mass of glass microspheres in an oven at 80°C for 12 hours to remove moisture, then disperse them in absolute ethanol, add 2 parts by mass of silane coupling agent, stir at 80°C for 1.5h, filter, and put them in to dry at 90°C box, add 2h to fully react completely, and get modified glass beads.

[0066] Put 100 parts by mass of vermiculite powder into a high-speed mixer, control the temperature at 120°C, stir to remove water for 2 hours, then lower the temperature of the material to 80°C, add tris(dioctylpyrophosphoryloxy)isopropyl titanate and Mix 30g of isopropanol (mass ratio 1:1), keep the temperature and stir for 30min, then raise the temperature to 120°C, remove all isopropanol, stir and cool at low speed to obtain modified vermiculite powder.

[0067] The modified sound-absorbing filler is obtained by uniformly mixing modified vermiculite powder and modified glass microspheres at a mas...

Embodiment 1

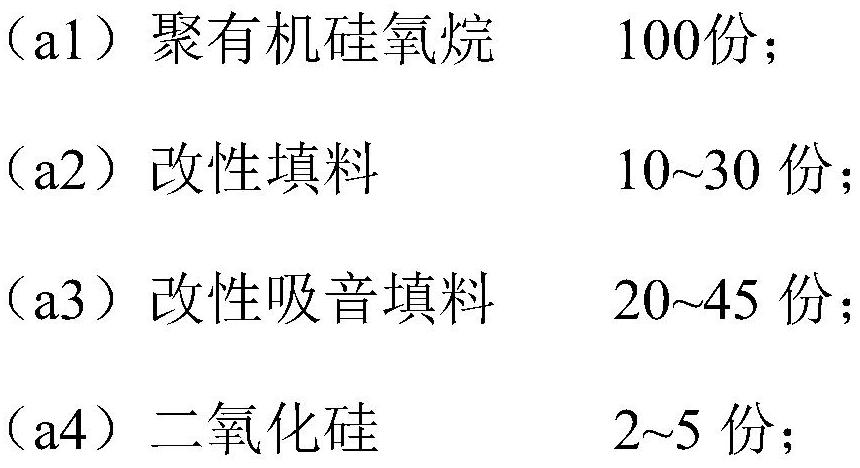

[0071] Component A: Put 100 parts by mass of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 1000mPa·s into a planetary stirring tank, add 30 parts by mass of modified calcium carbonate, and use the precipitation method of silazane surface treatment 5 parts by mass of silicon dioxide were stirred evenly at a high speed, and then 20 parts by mass of a modified sound-absorbing filler were added, stirred and mixed uniformly at a medium speed to obtain component A.

[0072] Component B: In the planetary machine, add 50 parts by mass of methyl-terminated polyorganosiloxane with a viscosity of 1000mPa·s, and add 15 parts by mass of polyethyl silicate, methyl trimethyl 14 parts by mass of ethoxysilane, 7 parts by mass of tris(trimethoxysilylmethyl)isocyanurate, 7 parts by mass of aminopropyltriethoxysilane, 3-(2,3-glycidoxy)propane 7 parts by mass of trimethoxysilane, 0.7 parts by mass of dibutyltin dilaurate, mixed uniformly, and discharged to obtain component B.

[0073] Mi...

Embodiment 2

[0075] Component A: Put 100 parts by mass of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 1000mPa·s into a planetary stirring tank, add 20 parts by mass of modified calcium carbonate, and precipitated by silazane surface treatment 2 parts by mass of French silica, stirred evenly at high speed, then added 30 parts by mass of modified sound-absorbing filler, stirred and mixed uniformly at medium speed to obtain component A.

[0076] Component B: In the planetary machine, add 50 mass parts of methyl-terminated polyorganosiloxane with a viscosity of 500mPa·s, and add 14 mass parts of polyethyl silicate, methyl trimethyl 15 parts by mass of ethoxysilane, 7 parts by mass of three (trimethoxysilyl methyl) isocyanurate, 7 parts by mass of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, 7 parts by mass of 3- 7 parts by mass of (2,3-glycidoxy)propyltrimethoxysilane and 0.5 part by mass of dibutyltin dilaurate were mixed uniformly and discharged to obtain component B.

[0077]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com