Preparation method of three-dimensional reticular silicon carbide ceramic reinforced aluminum-based composite material

A technology of reticulated silicon carbide and reinforced aluminum base, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of increased material manufacturing cost, low production efficiency, low production efficiency, etc., to achieve The effect of interfacial reaction control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

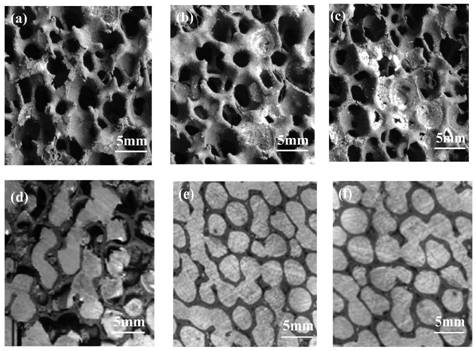

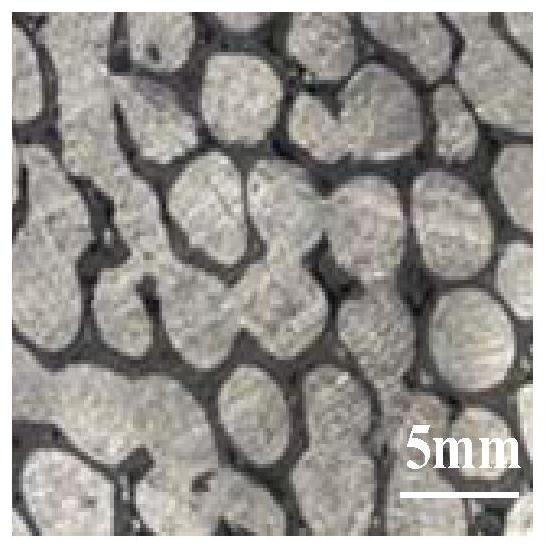

[0052] The three-dimensional mesh silicon carbide ceramic reinforced aluminum matrix composite material provided in this embodiment includes the following steps:

[0053] (1): Surface of the three-dimensional mesh porous silicon carbide ceramic (30 ppi, commercially available) surface is carried out (mixed acids used by acid dip "is a mixed acid solution of diluted concentrated nitric acid and concentrated hydrofluoric acid. Among them, the volume ratio of concentrated nitric acid and concentrated hydrofluoric acid is 5: 1; the ultrasonic treatment time is 1 to 20 minutes, and the mixed acid is a mixed acid solution having a diluted volume concentration of 35 to 40%, a mixed acid solution of concentrated hydrofluoric acid. The surface is roughened, then polishing the ceramic corner (electronic grinding wheel grinding treatment by the three00 # electronic grinding wheel side faces the sample, no spark is standard, the surface is flat; then use 200 # sandpaper light Grinding, 200 # ...

Embodiment 2

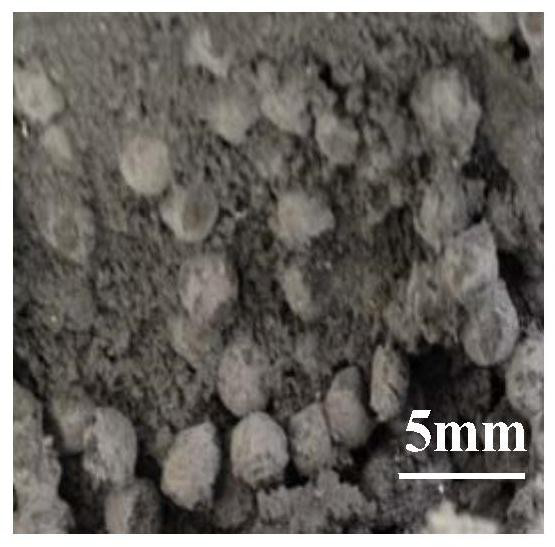

[0065] Unlike Example 1, the three-dimensional mesh porous silicon carbide ceramic is prepared in step (1), and the specific steps are as follows:

[0066] Including two centrifugal trap slurry SiC slurry molding and secondary pilot sintering techniques, the first centrifugal flue is a pretreatment of organic foam, immersed in the flask and binder designed by formulation. In the slurry, the slurry is performed, and the slurry is fully wetted and filling the foam; then centrifuged at the centrifuge to remove excess slurry, prepared uniformly coating, no porous body without blocking holes; Room temperature drying; the second centrifugal trap is to dry the ceramic slurry in the ceramic slurry again, and simultaneously impregnate the slurry into the foam, fully impregnated; then, remove extra Slurry; prepared a porous body for uniform structure; Finally after the elimination, high temperature sintering, then a piping, strengthen supplementary part of the hole after sintering, to ensur...

Embodiment 3

[0072] Different from the examples, three-dimensional mesh porous silicon carbide ceramic in step (1) is 40 ppi.

[0073] Step (1) coarse the laser etching treatment.

[0074] The particle diameter of the aluminum alloy powder in step (3) is 0.5 mm.

[0075] Step (4) The amount of the aluminum alloy powder is 75% of the total amount of all three-dimensional mesh porous ceramic holes.

[0076] In step (5), in a nitrogen environment, heated to 1200 ° C, and then turned to an argon environment, then transferred to a argon environment, and then heated after 1 h, stop heating, and cooled to the room. The three-dimensional mesh silicon carbide ceramic reinforced aluminum matrix composite is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com