A kind of preparation method of three-dimensional network silicon carbide ceramic reinforced aluminum matrix composite material

A reticulated silicon carbide, reinforced aluminum-based technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problem of increased material manufacturing cost, limited material shape and size, complex composite process, etc. problem, to achieve the effect of interface response control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The preparation method of the three-dimensional network silicon carbide ceramic reinforced aluminum matrix composite material provided by this embodiment includes the following steps:

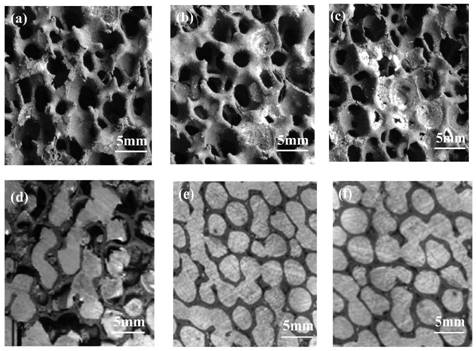

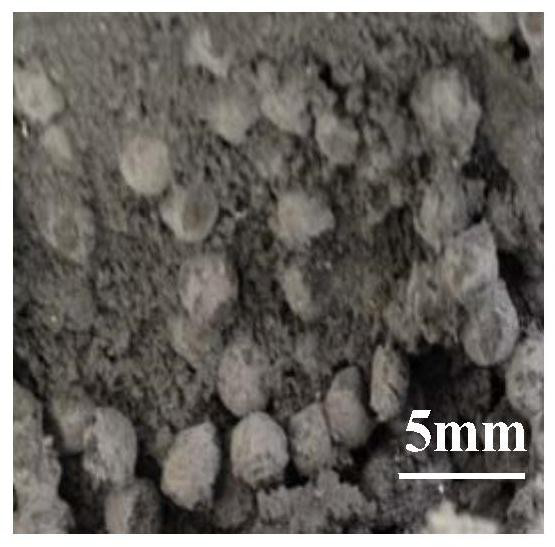

[0053] (1): The surface of three-dimensional mesh porous silicon carbide ceramics (30PPI, commercially available) is subjected to acid leaching and roughening treatment (the mixed acid used in the acid leaching and coarsening treatment is a mixed acid solution of diluted concentrated nitric acid and concentrated hydrofluoric acid, The volume ratio of concentrated nitric acid and concentrated hydrofluoric acid is 5:1; the ultrasonic treatment time is 1 to 20 minutes, and the mixed acid is a mixed acid solution of concentrated nitric acid and concentrated hydrofluoric acid with a diluted volume concentration of 35 to 40%) to make The surface is roughened, and then the ceramic corners are ground (electronic grinding wheel grinding is used to grind the sample on the side of a 300# electronic ...

Embodiment 2

[0065] The difference from Example 1 is that in step (1), the three-dimensional network porous silicon carbide ceramic is prepared by itself, and the specific steps are as follows:

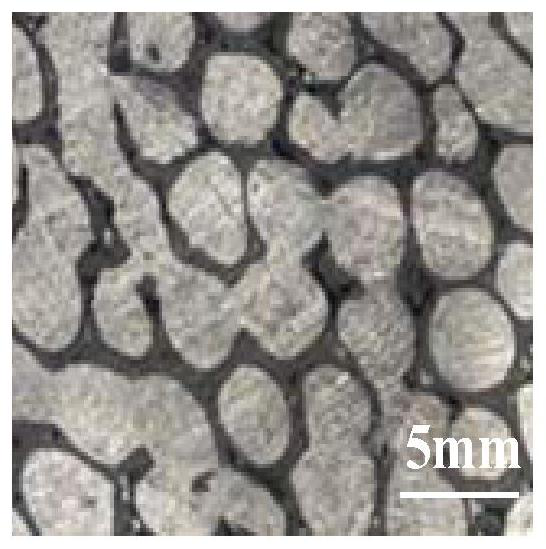

[0066] Including two times of centrifugal slurry SiC slurry forming and secondary slurry sintering technology, the first centrifugal slurry is to immerse the pretreated organic foam into the formula designed containing sintering aids and binders. In the slurry, knead to fully wet the slurry and fill the foam; then centrifuge at high speed on a centrifuge to remove excess slurry, and prepare a porous body that is uniformly coated with a thin layer of slurry without blocking pores; Drying at room temperature; the second centrifugal slurry is to immerse the porous body dried in the previous step into the ceramic slurry again, and at the same time apply a vacuum to make the slurry completely enter the foam body and fully immerse; then, centrifuge again to remove excess A porous body with the required ...

Embodiment 3

[0072] Different from the embodiment, the three-dimensional network porous silicon carbide ceramic in step (1) is 40PPI.

[0073] In step (1), laser etching is used for roughening.

[0074] The particle size of the aluminum alloy powder in step (3) is 0.5 mm.

[0075] Step (4) The filling amount of the aluminum alloy powder is 75% of the total amount of the pores of all three-dimensional network porous ceramics.

[0076] In step (5), in a nitrogen environment, heated to 1200 ° C, and kept for 0.5 h, then immediately changed to an argon environment, continued to heat up to 1300 ° C, and after holding for 1 h, stopped heating, and cooled to room temperature with the furnace to take out, After processing, a three-dimensional network silicon carbide ceramic reinforced aluminum matrix composite material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com