Fermentation medium and application thereof

A fermentation medium and yeast powder technology, applied in fermentation, microorganism-based methods, and adding compounds to stimulate growth, etc., can solve problems such as differences in the physiological properties of molds, solve the viscosity of fermentation broth, increase yield, and ensure stability. Effect

- Summary

- Abstract

- Description

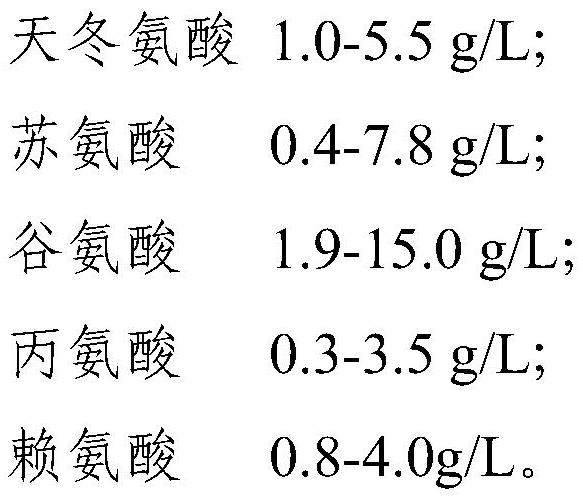

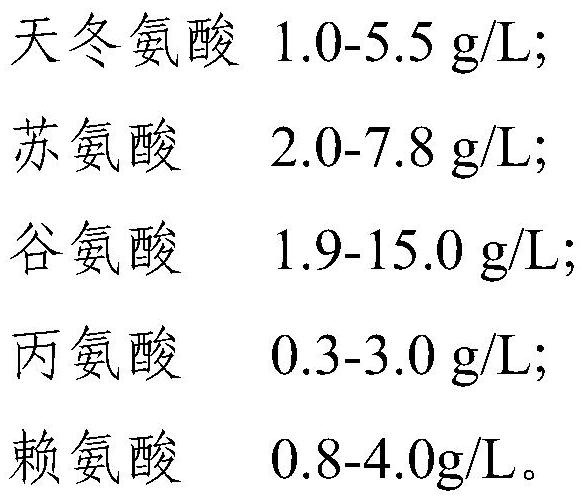

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1 prepares β-carotene

[0059] This embodiment provides a method for preparing β-carotene by using B. trispora. The steps are as follows:

[0060] 1) Slant culture: prepare PDA slant medium (glucose 20g / L, agar powder 25g / L, peeled potatoes 200g / L; cut potatoes into 1cm cubes, add deionized water to boil for 30min, filter with four layers of gauze after cooling, Take the filtered supernatant and add glucose and agar powder). Take the spore suspensions of B. trispora positive bacteria and B. trispora negative bacteria, spread them on the PDA slant medium respectively, and cultivate them in a constant temperature incubator at 25°C for 5-7 days;

[0061] 2) Seed culture: Shovel positive bacteria and negative bacteria from the slant surface of B. trispora positive bacteria and negative bacteria strains with an inoculation shovel, respectively, and inoculate them into 1000mL triangular flasks containing 150mL seed culture medium respectively. Cultivate for 48 ho...

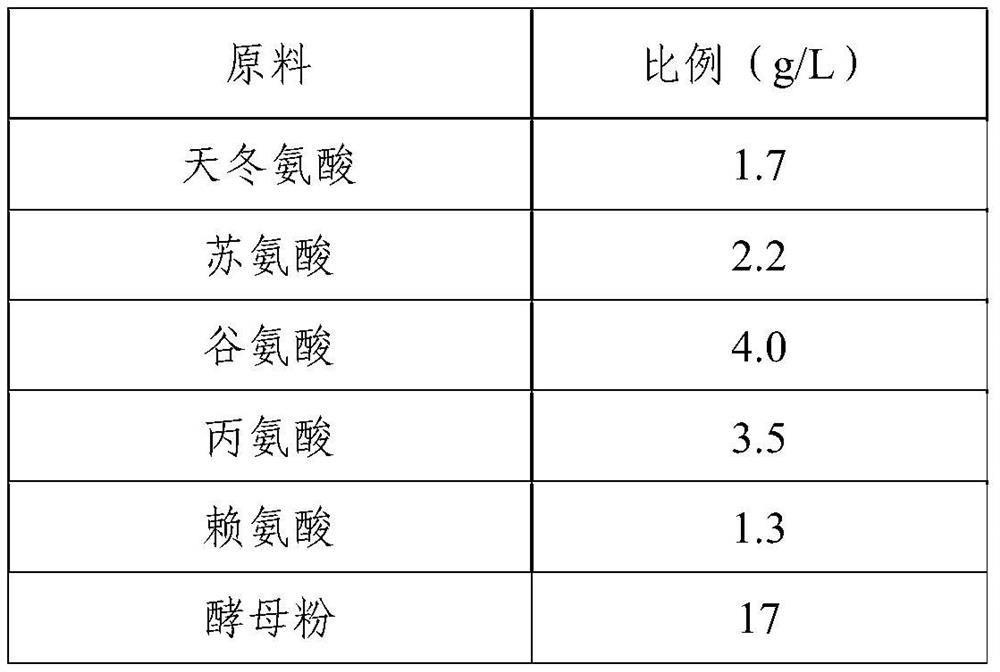

Embodiment 2

[0067] Embodiment 2 prepares β-carotene

[0068] This example provides a method for preparing β-carotene by using B. trispora. The difference from Example 1 is that the formulation of the fermentation medium is as follows (the content of alanine is increased), and the total nitrogen content remains the same.

[0069] Table 2

[0070]

[0071]

Embodiment 3

[0072] Embodiment 3 prepares β-carotene

[0073] This example provides a method for preparing β-carotene by using B. trispora. The difference from Example 1 is that the formulation of the fermentation medium is as follows (reduced amount of threonine added).

[0074] table 3

[0075] raw material Ratio (g / L) aspartic acid 1.7 threonine 0.5 glutamic acid 4.0 Alanine 0.6 Lysine 1.3 yeast 22 Potassium dihydrogen phosphate 1 glucose 30 magnesium sulfate 0.5 Sunflower seed oil 45

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com