Method for manufacturing ultrathin glass by etching

An ultra-thin glass and etching technology, applied in coatings and other directions, can solve problems such as weakening the compressive strength and toughness of glass substrates, broken screens, uneven stress distribution on the glass surface, etc., to improve structural stability and mechanical strength. , prevent chipping, improve the effect of optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

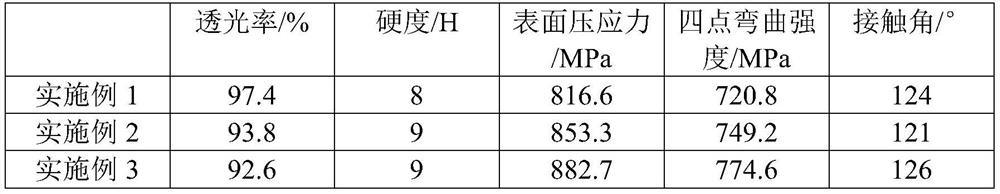

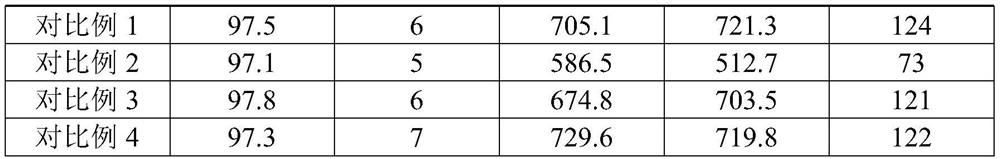

Embodiment 1

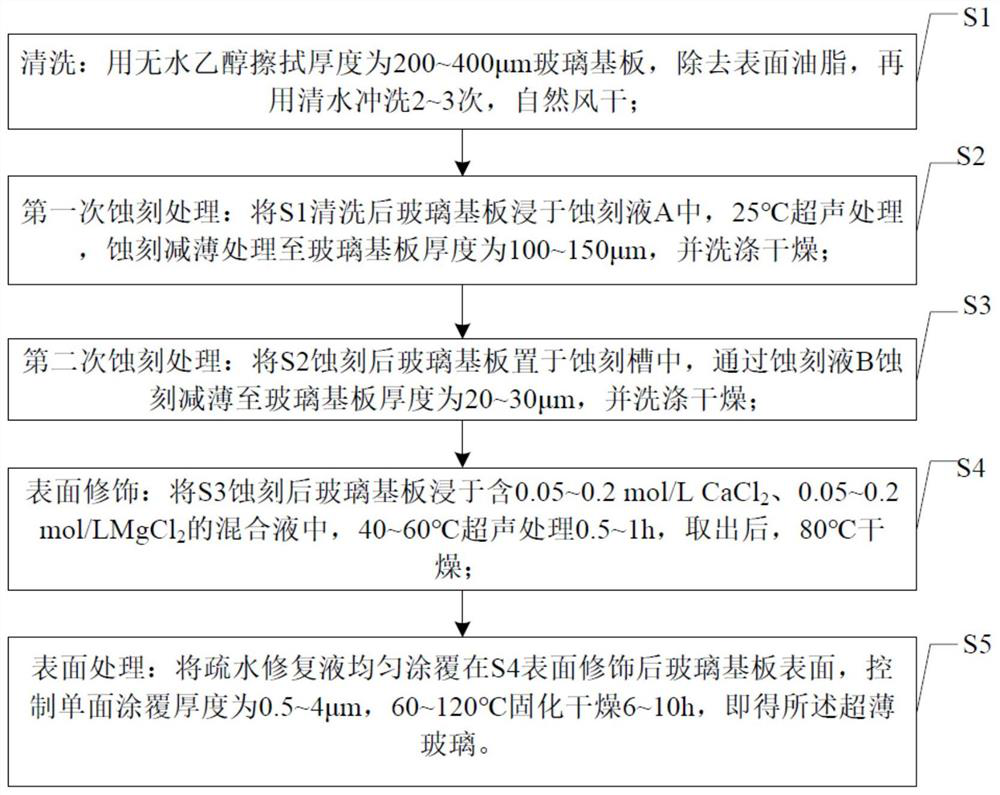

[0031] The method for making ultra-thin glass by etching: adopt etchant A and etchant B to etch respectively, use Ca 2+ , Mg 2 + After the surface is modified, the surface is treated with a hydrophobic repair solution; specifically, the following steps are included:

[0032] S1: Cleaning: Wipe the glass substrate with a thickness of 200 μm with absolute ethanol to remove surface grease, rinse twice with water, and air dry naturally;

[0033] S2: The first etching treatment: immerse the glass substrate after cleaning in S1 in etching solution A, ultrasonically treat at 25°C, etch and thin the glass substrate until the thickness of the glass substrate is 100 μm, and wash and dry;

[0034] The etching solution A uses water as a solvent and includes the following molar concentration components: hydrofluoric acid 1.5 mol / L, hydrochloric acid 0.5 mol / L, sodium fluorosilicate 1.0 mol / L, sodium lauryl sulfate 0.1 mol / L ;

[0035] S3: second etching treatment: place the glass subst...

Embodiment 2

[0041] The method for making ultra-thin glass by etching: adopt etchant A and etchant B to etch respectively, use Ca 2+ , Mg 2 + After the surface is modified, the surface is treated with a hydrophobic repair solution; specifically, the following steps are included:

[0042] S1: Cleaning: Wipe the glass substrate with a thickness of 300 μm with absolute ethanol to remove surface grease, then rinse with water for 3 times, and let it dry naturally;

[0043] S2: The first etching treatment: immerse the glass substrate after cleaning in S1 in etching solution A, ultrasonically treat at 25°C, etch and thin the glass substrate until the thickness of the glass substrate is 125 μm, and wash and dry;

[0044] The etching solution A uses water as a solvent and includes the following molar concentration components: 2 mol / L hydrofluoric acid, 1 mol / L hydrochloric acid, 1.2 mol / L sodium fluorosilicate, and 0.15 mol / L sodium lauryl sulfate;

[0045] S3: second etching treatment: place the ...

Embodiment 3

[0051] The method for making ultra-thin glass by etching: adopt etchant A and etchant B to etch respectively, use Ca 2+ , Mg 2 + After the surface is modified, the surface is treated with a hydrophobic repair solution; specifically, the following steps are included:

[0052] S1: Cleaning: Wipe the glass substrate with a thickness of 400 μm with absolute ethanol to remove surface grease, then rinse with water for 3 times, and let it dry naturally;

[0053] S2: The first etching treatment: immerse the glass substrate after cleaning in S1 in etching solution A, ultrasonically treat at 25°C, etch and thin the glass substrate until the thickness of the glass substrate is 150 μm, and wash and dry;

[0054] The etching solution A uses water as a solvent and includes the following molar concentration components: 3 mol / L hydrofluoric acid, 1.5 mol / L hydrochloric acid, 1.5 mol / L sodium fluorosilicate, and 0.2 mol / L sodium lauryl sulfate;

[0055] S3: second etching treatment: place t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com