A kind of lanthanum lithium zirconate solid electrolyte and preparation method thereof

A technology of solid electrolyte, lanthanum lithium zirconate, which is applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve the problem of low ionic conductivity of solid electrolytes, shorten the sintering reaction time, improve ionic conductivity, and relatively The effect of high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

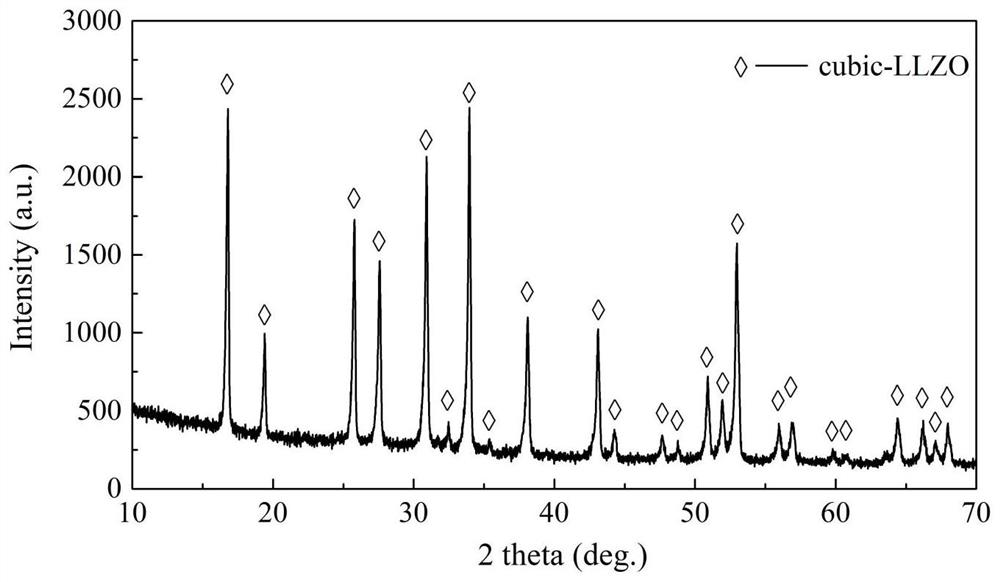

[0034] combine figure 1 As shown, the embodiment of the present invention provides a method for preparing a lithium lanthanum zirconate solid electrolyte, comprising the following steps:

[0035] Step S1, respectively preparing lithium lanthanum zirconate powder and lithium germanate powder;

[0036] Step S2, coating the lithium germanate powder on the surface of the lithium lanthanum zirconate powder to obtain a composite powder;

[0037] Step S3, pre-pressing and cold isostatic pressing the composite powder to obtain a ceramic green body, and liquid-phase sintering the ceramic green body to obtain a lithium lanthanum zirconate solid electrolyte.

[0038] Since the traditional pressureless sintering method requires a higher sintering temperature and a longer sintering time, a large amount of lithium elements are volatilized, which not only reduces the concentration of lithium ions inside the electrolyte, but also reduces the relative density of the electrolyte. A small amount...

Embodiment 1

[0069] This embodiment provides a method for preparing a lithium lanthanum zirconate solid electrolyte, comprising the following steps:

[0070] 1.1 In parts by weight, weigh 25 parts of Li 2 CO 3 , 45 La 2 o 3 , 18 parts of ZrO 2 and 12 Ta 2 o 5 , will Li 2 CO 3 , La 2 o 3 , ZrO 2 and Ta 2 o 5 After mixing evenly, the mixed powder is obtained, and the mixed powder is added to the ball milling tank, and the grinding ball is added to the ball milling tank according to the mass ratio of the mixed powder and the grinding ball as 1:3, and the mass ratio of isopropanol to the mixed powder is 1.5 : 1, add isopropanol in the ball mill jar, after the ball mill jar is sealed, at a rotating speed of 400r / min, ball mill for 12h, after the balls are removed, the first slurry is obtained, and the first slurry is passed through a 300-mesh screen After filtering, dry at 60°C for 12 hours to obtain evenly mixed raw material mixed powder; put the raw material mixed powder into a c...

Embodiment 2

[0076] This example provides a method for preparing a lithium lanthanum zirconate solid electrolyte. The preparation method in this example is the same as that in Example 1, with the difference that:

[0077] When preparing lithium germanate powder, according to Li 2 CO 3 and GeO 2 The molar ratio of Li is 60:40 2 CO 3 and GeO 2 Mix evenly to obtain lithium germanate powder (ie 0.6Li 2 O-0.4GeO 2 ).

[0078] When preparing the composite powder, according to the following parts by weight: 96 parts of lithium lanthanum zirconate powder and 4 parts of lithium germanate powder, the lithium lanthanum zirconate powder and lithium germanate powder were evenly mixed to prepare the composite powder.

[0079] When preparing the lanthanum lithium zirconate solid electrolyte, the ceramic green body was raised from normal temperature to 1000 °C at a heating rate of 5 °C / min, and then the ceramic green body was raised from 1000 °C to 1120 °C at a heating rate of 3 °C / min, and sintere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com