A kind of low-temperature fast-curing RFID electronic paste and preparation method thereof

An electronic paste, fast curing technology, applied in the field of radio frequency identification, can solve the problems of reduced silver content, long curing time, warpage of coated paper, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

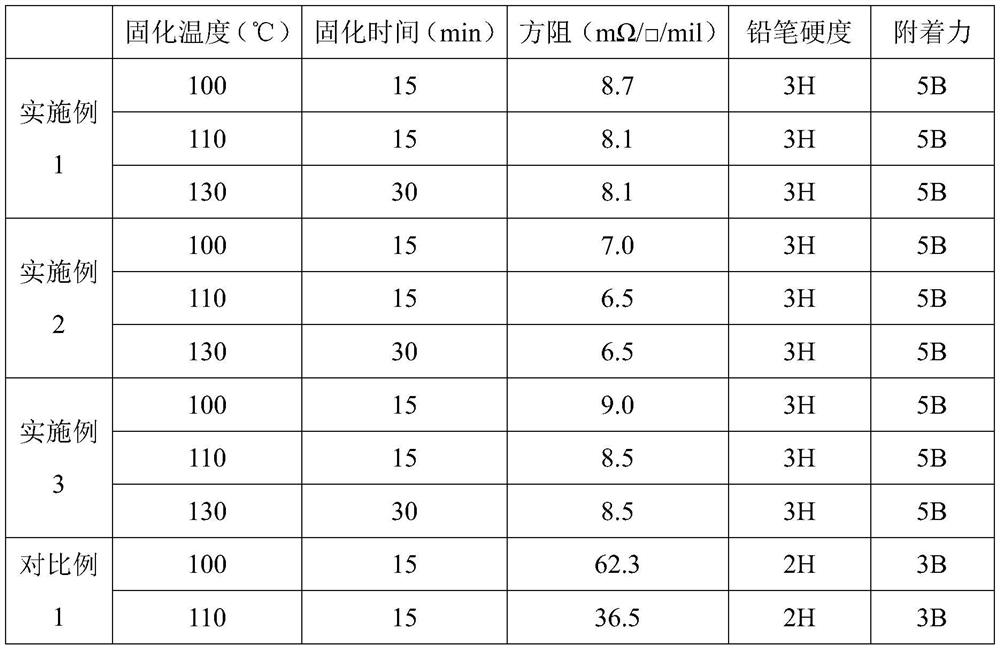

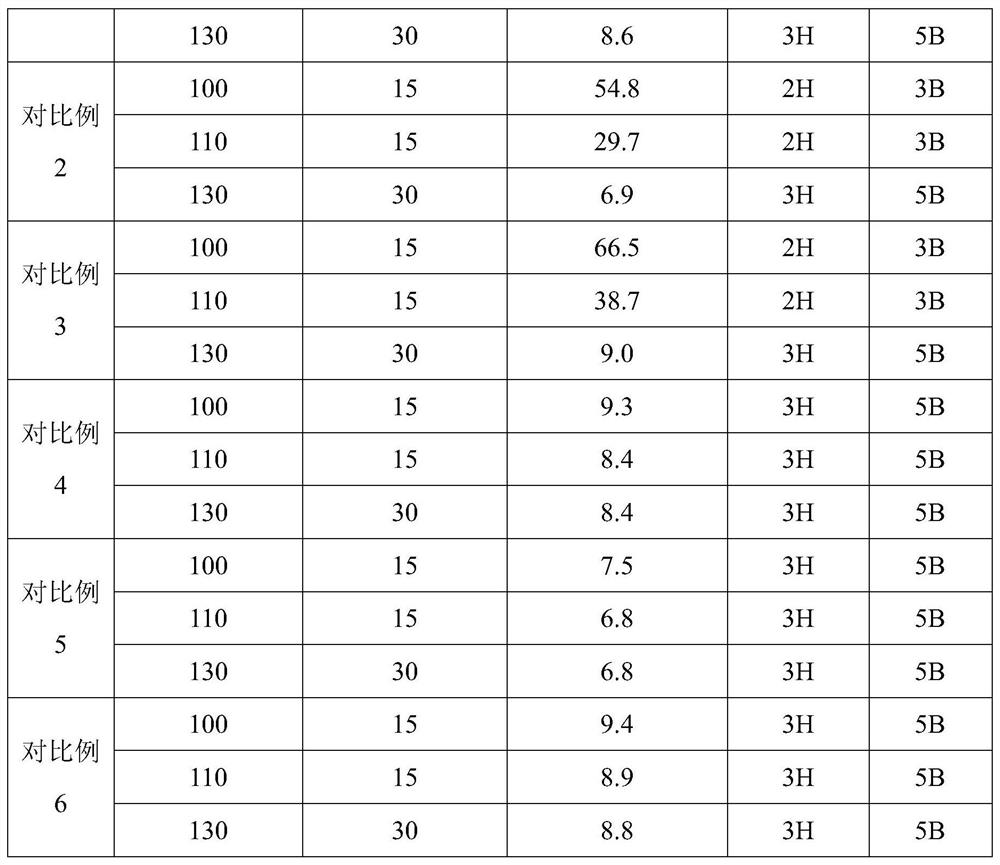

Examples

preparation example Construction

[0021] The present invention also proposes a method for preparing a low-temperature fast-curing RFID electronic paste, comprising the following steps:

[0022] (1) Take by weight (35~45): (3~5): (7~10): (40~50) take flake silver powder, nickel powder, polymer resin and organic solvent;

[0023] Preferably, the average particle size of the flaky silver powder is 5-7 μm; the average particle size of the nickel powder is 0.5-1 μm, and the micron-sized nickel powder can fill the gaps of the flaky silver powder when they are overlapped, thereby increasing Conductive pathways between large powders.

[0024] Preferably, the polymer resin is at least one of polyester resin, polyurethane resin, and polyethylene-vinyl alcohol resin. The polymer resin is dissolved in an organic solvent to form a jelly, which is used to overlap the flake silver powder to form a conductive path.

[0025] Preferably, the organic solvent is dimethyl malonate, dimethyl succinate, dimethyl glutarate, ethylen...

Embodiment 1

[0036] The present embodiment provides a kind of RFID electronic paste of low temperature rapid solidification, comprises each component of following weight: 43.3% flaky silver powder, 3.8% nickel powder, 9.6% polyester resin, 43.3% dimethyl malonate and N - Methylpyrrolidone.

[0037] This embodiment also provides a method for preparing a low-temperature fast-curing RFID electronic paste, comprising the following steps:

[0038] (1) Take by weighing 45g average particle diameter of flaky silver powder, 4g average particle diameter of 0.5~1 μm nickel powder, 10g polyester resin, 40g dimethyl malonate, 5g N-methylpyrrolidone;

[0039] (2) Add the polyester resin weighed in step (1) into the mixed solvent of dimethyl malonate and N-methylpyrrolidone, heat and stir at 90°C for 3h until the polyester resin is completely dissolved, and use a 300-mesh filter to remove the insolubles to obtain the organic carrier;

[0040] (3) Place the flake silver powder and nickel powder weighed...

Embodiment 2

[0044] The present embodiment provides a kind of RFID electronic paste of low temperature fast solidification, comprises each component of following weight: 43.5% flaky silver powder, 4.3% nickel powder, 8.7% acrylic resin, 43.5% dimethyl succinate and dipropylene glycol n-propyl ether.

[0045] This embodiment also provides a method for preparing a low-temperature fast-curing RFID electronic paste, comprising the following steps:

[0046](1) Take by weighing 50g average particle diameter be the flaky silver powder of 5~7 μm, 5g average particle diameter be the nickel powder of 0.5~1 μm, 10g acrylic resin and 45g dimethyl succinate, 5g dipropylene glycol n-propyl ether;

[0047] (2) Add the acrylic resin weighed in step (1) into the mixed solvent of dimethyl succinate and dipropylene glycol n-propyl ether, heat and stir at 95°C for 2.8h until the acrylic resin is completely dissolved, and filter through 250 mesh Net filtration removes insoluble matter, obtains organic carrier...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com