Anti-freezing environment-friendly diluted asphalt and preparation method thereof

A technology of diluting asphalt and anti-icing, applied in building insulation materials, building components, buildings, etc., can solve the problems of weak high temperature performance, strong temperature sensitivity, high price, etc., and achieve strong aging resistance, low thermal conductivity, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

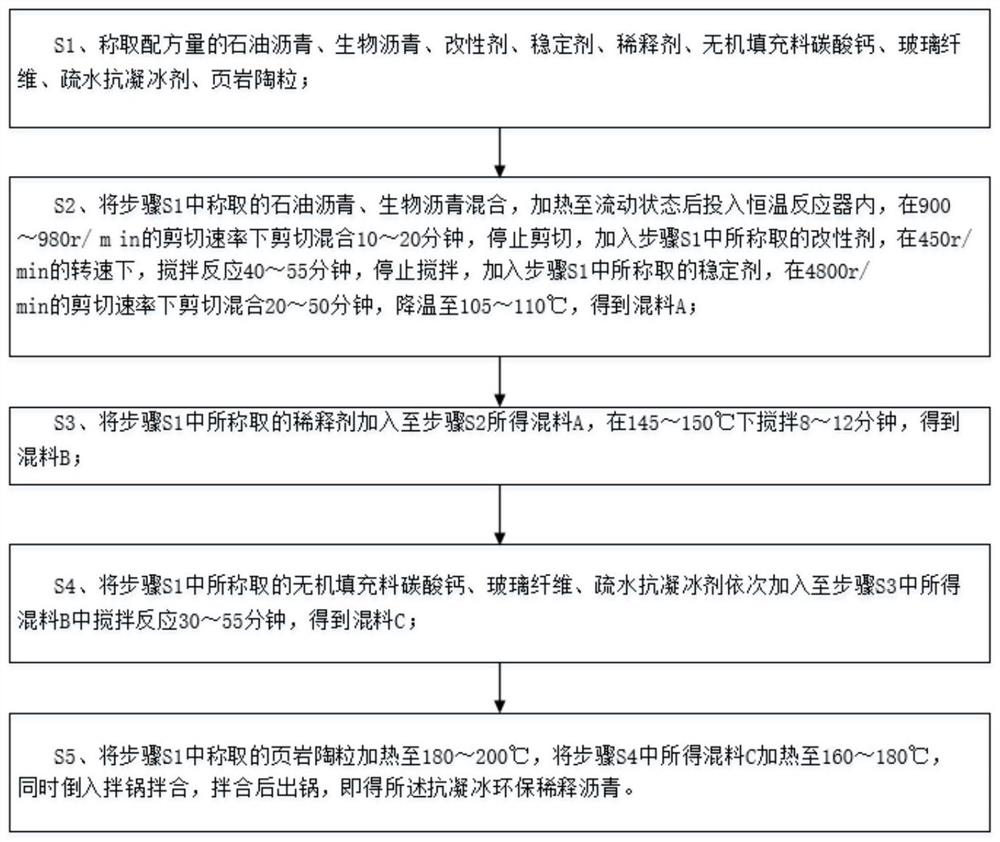

Method used

Image

Examples

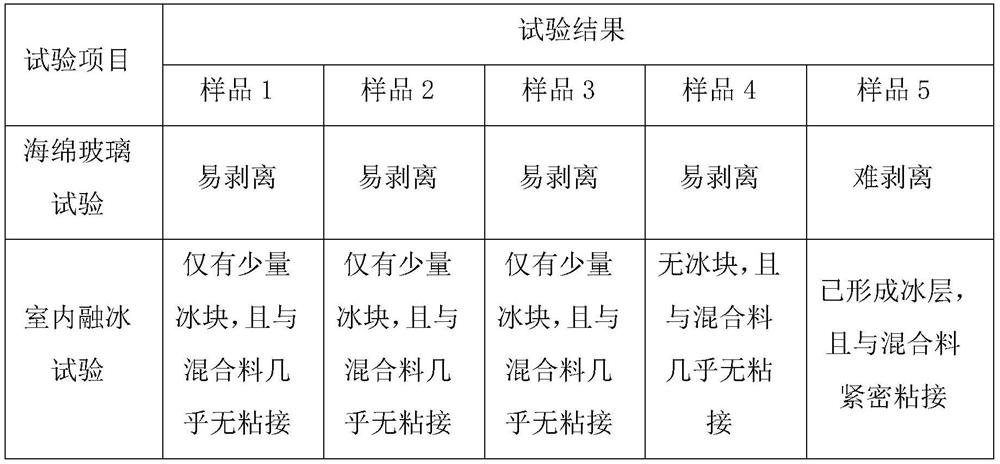

Embodiment 1

[0028] An anti-icing environment-friendly dilute asphalt, including the following raw materials by weight: petroleum asphalt 51, biological asphalt 32g, modifier 10g, stabilizer 4g, diluent 26g, inorganic filler calcium carbonate 15g, glass fiber 14g, hydrophobic anticoagulation Ice agent 6g, shale ceramsite 8g.

[0029] Wherein, the modifying agent in this embodiment is SBS, the stabilizer is sulfur, the diluent is diesel oil; the inorganic filler calcium carbonate is light calcium carbonate.

[0030] Wherein, the particle size of the glass fiber in this embodiment is 35 μm, and the length of the glass fiber is 2 mm.

[0031] Among them, the hydrophobic anti-icing agent in this embodiment is made of the following components by weight: 3 g of methyl vinyl phenyl silicone rubber, 1 g of anti-icing ice chloride salt, 1 g of silicone hydrophobic agent, 0.05 g of ethyl acetate, Magnesium oxide 0.25g, silane coupling agent 0.7g.

[0032] Wherein, the particle size of the shale ce...

Embodiment 2

[0041] An anti-icing environment-friendly diluted asphalt, including the following raw materials: 80g of petroleum asphalt, 32g of biological asphalt, 26g of modifier, 12g of stabilizer, 50g of diluent, 24g of inorganic filler calcium carbonate, 25g of glass fiber, hydrophobic anticoagulation Ice agent 17.5g, shale ceramsite 21g.

[0042] Wherein, the modifying agent in this embodiment is SBS, the stabilizer is sulfur, the diluent is diesel oil; the inorganic filler calcium carbonate is light calcium carbonate.

[0043] Wherein, the particle size of the glass fiber in this embodiment is 35 μm, and the length of the glass fiber is 2 mm.

[0044] Among them, the hydrophobic anti-icing agent in this embodiment is made of the following components: 5.2 g of methyl vinyl phenyl silicone rubber, 1 g of anti-icing chloride salt, 5 g of silicone hydrophobic agent, 2 g of ethyl acetate, magnesium oxide 2.8g, 2.5g of silane coupling agents.

[0045] Wherein, the particle size of the sh...

Embodiment 3

[0054] An anti-icing environment-friendly diluted asphalt, including the following raw materials: 62g of petroleum asphalt, 23g of biological asphalt, 25g of modifier, 8g of stabilizer, 32g of diluent, 20g of inorganic filler calcium carbonate, 20g of glass fiber, hydrophobic anticoagulation Ice agent 12g, shale ceramsite 15g.

[0055] Wherein, the modifying agent in this embodiment is SBS, the stabilizer is sulfur, the diluent is diesel oil; the inorganic filler calcium carbonate is light calcium carbonate.

[0056] Wherein, the particle size of the glass fiber in this embodiment is 35 μm, and the length of the glass fiber is 2 mm.

[0057] Among them, the hydrophobic anti-icing agent in this embodiment includes the following components: 4 g of methyl vinyl phenyl silicone rubber, 0.5 g of anti-icing chlorine salt, 1.5 g of silicone hydrophobic agent, 2 g of ethyl acetate, 2.2 g of magnesium oxide g, 1.8 g of silane coupling agent.

[0058] Wherein, the particle size of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com