A kind of degradable light conversion film and its preparation method and application

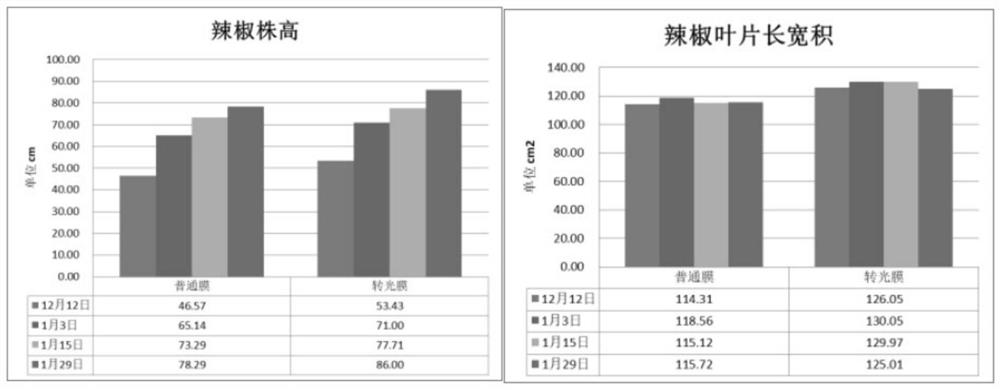

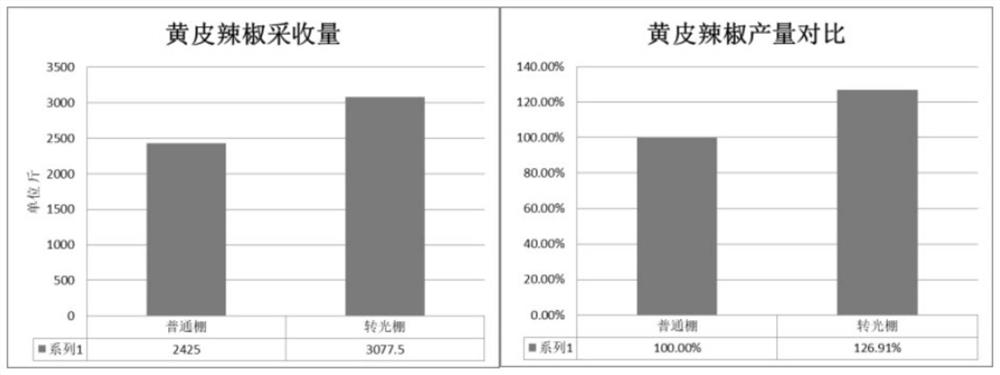

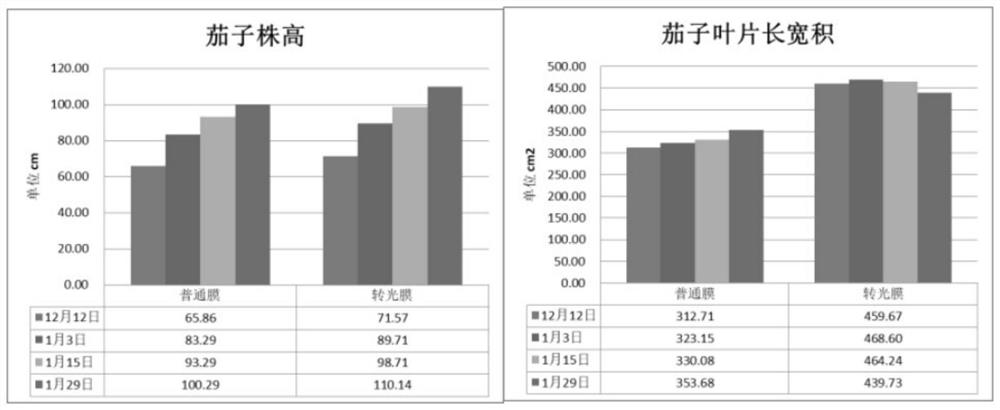

A film and light conversion technology, applied in the field of light conversion film, can solve the problems of film uniformity, low transmittance and mechanical properties, large difference in chain structure, lack of adhesion, etc., and achieve good light conversion performance. , the effect of increasing plant height and increasing leaf length and width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A degradable light-converting film of the present embodiment includes the following components by mass:

[0047] 100 parts of polylactic acid;

[0048] Light Conversion Agent Sr Coated with Silica and Surface Modified by Silane Coupling Agent 2 MgSi 2 O 7 :Eu 2+ ,Dy 3+ 0.8 servings.

[0049] The degradable light conversion film of the present embodiment is prepared by the following method:

[0050] (1) Take 0.75mmol CTAB, 2ml 0.1mol / L ammonia water and 15mL deionized water in a round-bottomed flask, after stirring CTAB completely dissolve, add 2g light conversion agent Sr 2 MgSi 2 O 7 :Eu 2+ ,Dy 3+ Continue to stir for 30min to make the light conversion agent completely dispersed in the solution, then quickly inject 15μL of n-silane ethyl ester, stir at 60-70°C for 24h, and then add 15μL of silane coupling agent 3-[3-carboxyallyl The amido]propyl triethoxysilane continued to stir and react for 12 hours, and after the reaction was completed, washing and dryin...

Embodiment 2

[0054] A degradable light-converting film of the present embodiment includes the following components by mass percentage:

[0055] 30 parts of methyl acrylate modified starch;

[0056] Silica-coated and surface-modified light conversion agent CaAl with silane coupling agent 2 O 4 :Eu 2+ ,Nd 3+ 0.6 servings;

[0057] 3 parts of ethylene-acrylic acid copolymer;

[0058] Polyethylene 70 parts.

[0059] The degradable light conversion film of the present embodiment is prepared by the following method:

[0060] (1) Take 0.75mmol CTAB, 2ml 0.1mol / L ammonia water and 15mL deionized water in a round-bottomed flask, after stirring CTAB completely dissolve, add 2g light conversion agent CaAl 2 O 4 :Eu 2+ ,Nd 3+Continue to stir for 30 minutes to completely disperse the light-transforming agent in the solution, then quickly inject 15 μL of n-silyl ethyl ester, stir and react at 60-70 °C for 24 hours, and then add 15 μL of silane coupling agent 3-[3-carboxyallyl Amido]propyltri...

Embodiment 3

[0064] A degradable light conversion film of this embodiment includes the following components by mass:

[0065]

[0066] The degradable light-converting film of this example is prepared by the following method:

[0067] (1) Take 0.5mmol CTAB, 1ml 0.1mol / L ammonia water and 20mL deionized water in a round bottom flask, stir to dissolve CTAB completely, then add 1g carbon quantum dot light conversion agent and continue stirring for 30min to make carbon quantum dots The light agent is completely dispersed in the solution, then quickly inject 5 μL of n-silyl ethyl ester, stir and react at 50-60 °C for 30 hours, and then add 5 μL of silane coupling agent N-(β-aminoethyl)-γ-aminopropyl Triethoxysilane was stirred and reacted for 10 hours. After the reaction was completed, it was washed and dried to obtain a light converting agent coated with silica and surface-modified by a silane coupling agent.

[0068] (2) Mix 0.2g of the surface-modified light-transforming agent obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com