5G chip processing technology

A processing technology and chip technology, applied in the field of microelectronics, can solve problems such as excessive grinding, low efficiency, and lower product quality, and achieve the effects of cost saving, high surface quality, and extended maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A 5G chip processing technology, comprising the following steps:

[0032] Step 1: Preliminary cutting, grinding and grinding of gallium nitride wafers

[0033] Step 2: place the ground gallium nitride wafer on a precision polisher for fine polishing;

[0034] Step 3: washing the surface of the gallium nitride wafer with a cleaning agent after fine polishing, and then drying to obtain a radio frequency chip material;

[0035] The fine polishing liquid used in the fine polishing treatment includes the following components by weight: 20-30wt% mixed abrasive particles, 0.4-0.8wt% corrosive agent, 0.3-0.7wt% oxidant, 0.001-0.01wt% accelerator, water balance.

[0036] The mixed abrasive particles are composed of purified silica sol and modified boron carbide in a mass ratio of 1:1; the particle size range of the purified silica sol is 60-90 nm; the particle size range of the modified boron carbide is 100-90 nm 130nm.

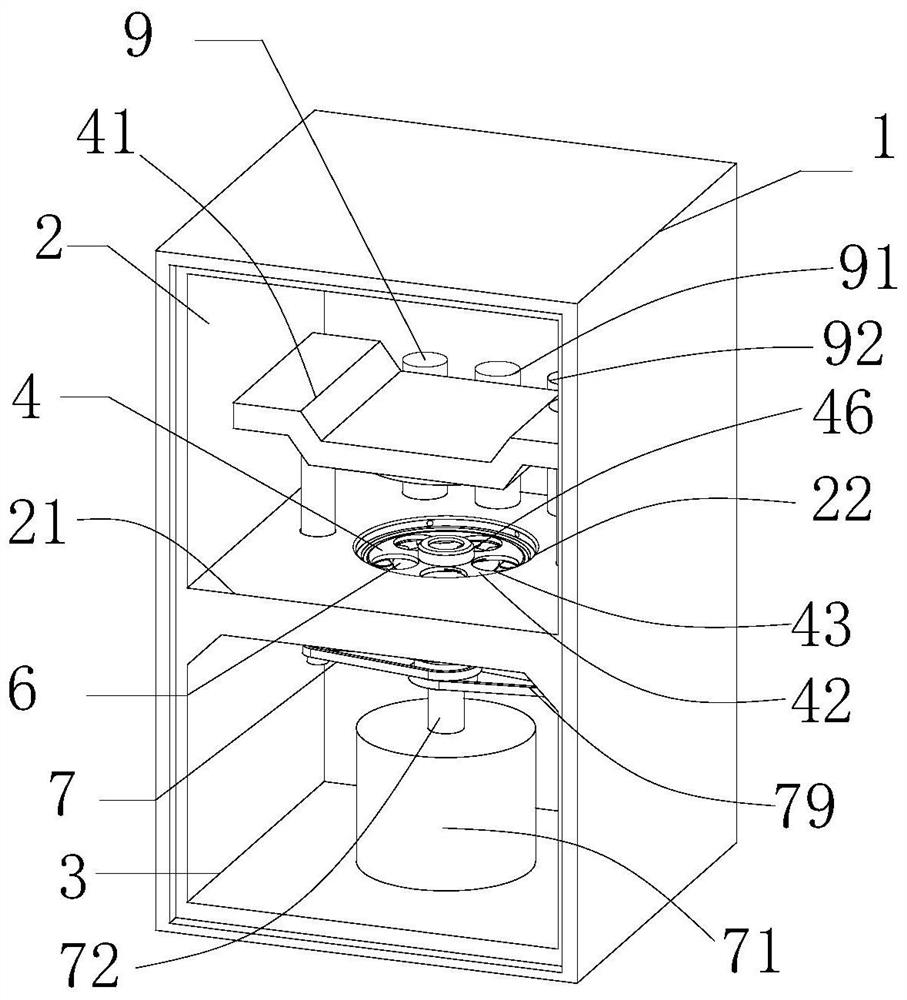

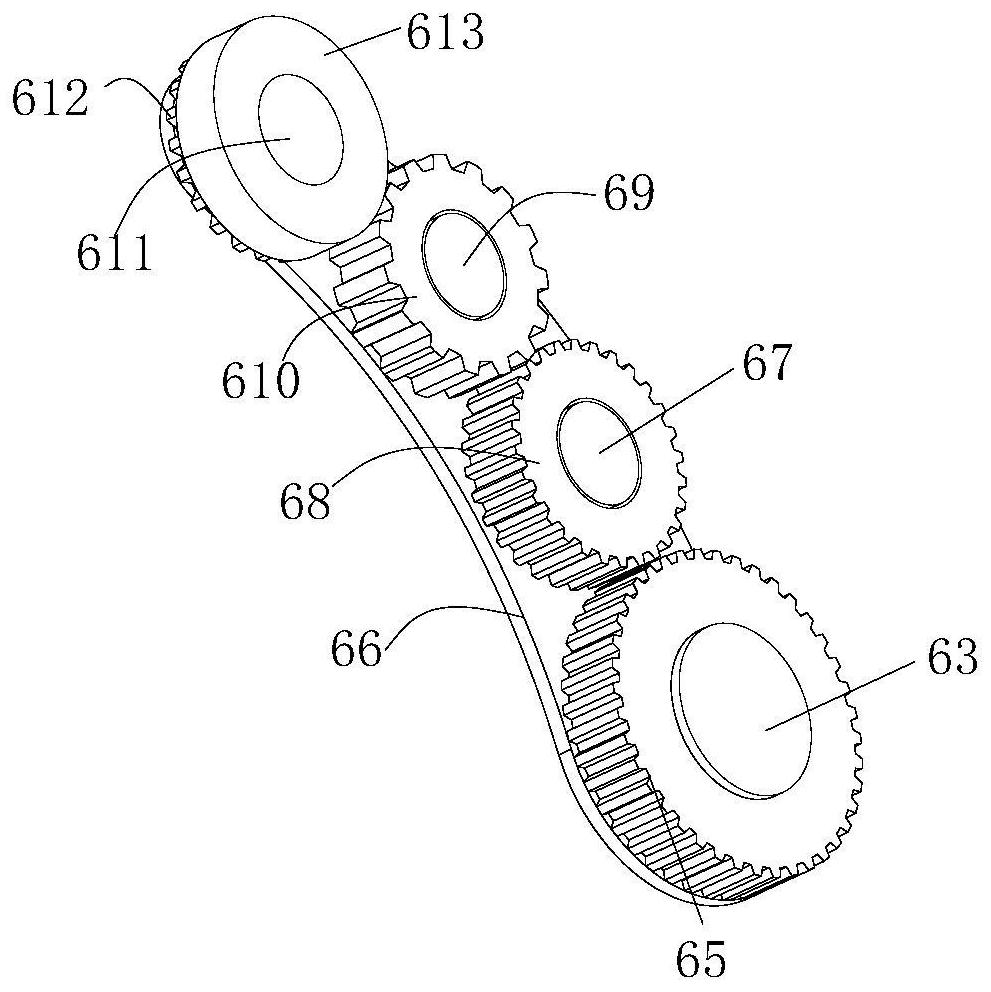

[0037] Wherein, the precision polishing apparatus in ...

Embodiment 2

[0047] A 5G chip processing technology, comprising the following steps:

[0048] Step 1: Preliminary cutting, grinding and grinding of gallium nitride wafers

[0049] Step 2: place the ground gallium nitride wafer on a precision polisher for fine polishing;

[0050] Step 3: washing the surface of the gallium nitride wafer with a cleaning agent after fine polishing, and then drying to obtain a radio frequency chip material;

[0051] The fine polishing liquid used in the fine polishing treatment includes the following components by weight: 25 wt % mixed abrasive particles, 0.6 wt % etchant, 0.5 wt % oxidant, 0.005 wt % accelerator, and water balance.

[0052] The mixed abrasive particles are composed of purified silica sol and modified boron carbide in a mass ratio of 1:1; the particle size range of the purified silica sol is 75 nm; the particle size range of the modified boron carbide is 115 nm.

[0053] The structure of the precision polishing apparatus in step 2 is the same...

Embodiment 3

[0055]A 5G chip processing technology, comprising the following steps:

[0056] Step 1: Preliminary cutting, grinding and grinding of gallium nitride wafers

[0057] Step 2: place the ground gallium nitride wafer on a precision polisher for fine polishing;

[0058] Step 3: washing the surface of the gallium nitride wafer with a cleaning agent after fine polishing, and then drying to obtain a radio frequency chip material;

[0059] The fine polishing liquid used in the fine polishing treatment includes the following components by weight: 30 wt % mixed abrasive particles, 0.8 wt % etchant, 0.7 wt % oxidant, 0.01 wt % accelerator, and water balance.

[0060] The mixed abrasive particles are composed of purified silica sol and modified boron carbide in a mass ratio of 1:1; the particle size range of the purified silica sol is 90 nm; the particle size range of the modified boron carbide is 130 nm.

[0061] The structure of the precision polishing apparatus in step 2 is the same a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com