Low-melting-point and high-strength low-silver cadmium-free manganese-free multi-element silver solder and preparation method thereof

A high-strength, low-melting-point technology, used in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of high silver content, cannot replace mature low-silver solder products, and high cost, and achieves a simple preparation method. Processability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

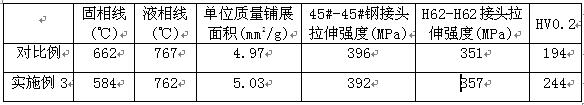

[0024] Embodiment 1: according to mass percentage, each component of low-melting-point cadmium-free manganese-free low-silver solder alloy of the present embodiment is selected as follows:

[0025] Ag: 21.0%, Zn: 34.5%, Sn: 1.5%, In: 1.0%, X: 0.2%, and the balance is Cu. The alloying element X in this example is P: 0.195%, Ce: 0.005%. The solidus temperature is 636°C, the liquidus temperature is 783°C, and the unit spread area on pure copper (copper) is 3.50 mm 2 / g, the tensile strength of the joint used for 45# steel is 377 MPa, the tensile strength of the joint used for H62 brass is 342 MPa, and the microhardness of the solder is 215 HV0.2.

Embodiment 2

[0026] Embodiment 2: According to the mass percentage, the components of the low-melting point cadmium-free manganese-free low-silver solder alloy in this embodiment are selected as follows:

[0027] Ag: 22.0%, Zn: 34.5%, Sn: 1.0%, X: 0.5%, and the balance is Cu. The alloy element X in this example is P: 0.49%, La: 0.01%. The solidus temperature is 613°C, the liquidus temperature is 772°C, and the unit spread area on pure copper is 3.80 mm 2 / g, the tensile strength of the joint used for 45# steel is 380 MPa, the tensile strength of the joint used for H62 brass is 337 MPa, and the microhardness of the solder is 215 HV0.2.

Embodiment 3

[0028] Embodiment 3: according to mass percentage, each component of low-melting point cadmium-free manganese-free low-silver solder alloy of the present embodiment is selected as follows:

[0029] Ag: 23.0%, Zn: 34.4%, Sn: 1.5%, X: 0.8%, and the balance is Cu. The alloy element X in this example is P: 0.785%, La: 0.01%, and Ce: 0.005%. The solidus temperature is 584°C, the liquidus temperature is 762°C, and the unit spread area on pure copper is 5.03 mm 2 / g, the tensile strength of the joint used for 45# steel is 392 MPa, the tensile strength of the joint used for H62 brass is 357 MPa, and the microhardness of the solder is 244 HV0.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com