Micro-carbon low-sulfur high-aluminum iron-free aluminum-magnesium-calcium alloy deoxidizer and preparation method and application thereof

A technology of aluminum-magnesium-calcium alloy and calcium alloy is applied in the field of metallurgy, which can solve the problems of low melting point, increased production cost, complicated burning operation, etc., and achieves the effect of good deoxidation effect and quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

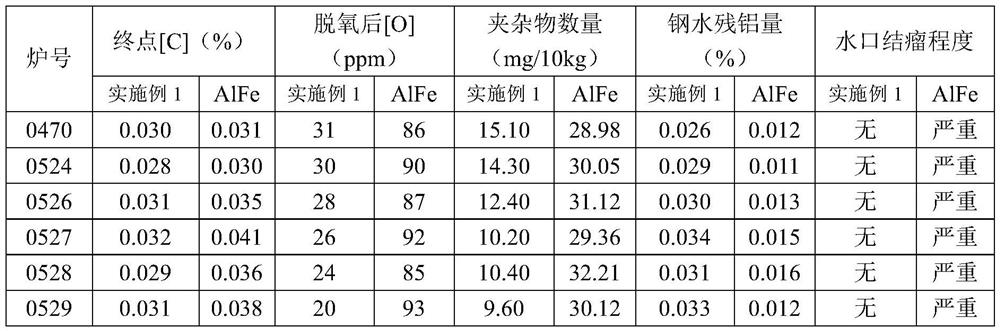

Examples

Embodiment 1

[0033] This embodiment is a preparation method of a micro-carbon, low-sulfur, high-aluminum, iron-free, aluminum-magnesium-calcium alloy deoxidizer, and the specific process is as follows:

[0034] (1) Adopt a 1000kg aluminum alloy pouring airtight resistance melting furnace, select pure aluminum ingots, metal calcium and metal magnesium according to the required ratio for material selection and weighing, and then add them into the melting furnace to melt to form an aluminum-magnesium-calcium alloy liquid;

[0035] During the melting process, the melting temperature is controlled at 680-850°C, and the melting time is controlled at 2.5-3.5 hours. During the entire melting process, the furnace mouth is sealed so that the aluminum-magnesium-calcium alloy liquid does not come into contact with the air, avoiding oxidation and burning. loss phenomenon;

[0036] In the melting process, the order of feeding is to firstly melt the pure aluminum ingot, then add metal calcium and metal ...

Embodiment 2

[0041] The difference from the examples is that only the ratio of aluminum, magnesium and calcium in the raw materials is different.

[0042] The chemical composition (percentage by weight) of the finished aluminum-magnesium-calcium alloy is: Al 71%, Mg 3%, Ca 25%, C 0.011%, S 0.013%, and the balance is impurities.

Embodiment 3

[0044] The difference from the examples is that only the ratio of aluminum, magnesium and calcium in the raw materials is different.

[0045] The chemical composition (percentage by weight) of the produced aluminum-magnesium-calcium alloy is: Al 88%, Mg 6%, Ca 5%, C 0.012%, S 0.014%, and the balance is impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com