Optical lens processing device

A technology for processing devices and optical lenses, which is applied in the direction of grinding/polishing safety devices, grinding drive devices, metal processing equipment, etc., can solve the problems of uneven grinding effect of the edge of the lens, low processing efficiency, waste of resources, etc., to achieve Reduce the labor load of personnel, improve work efficiency, and achieve uniform grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

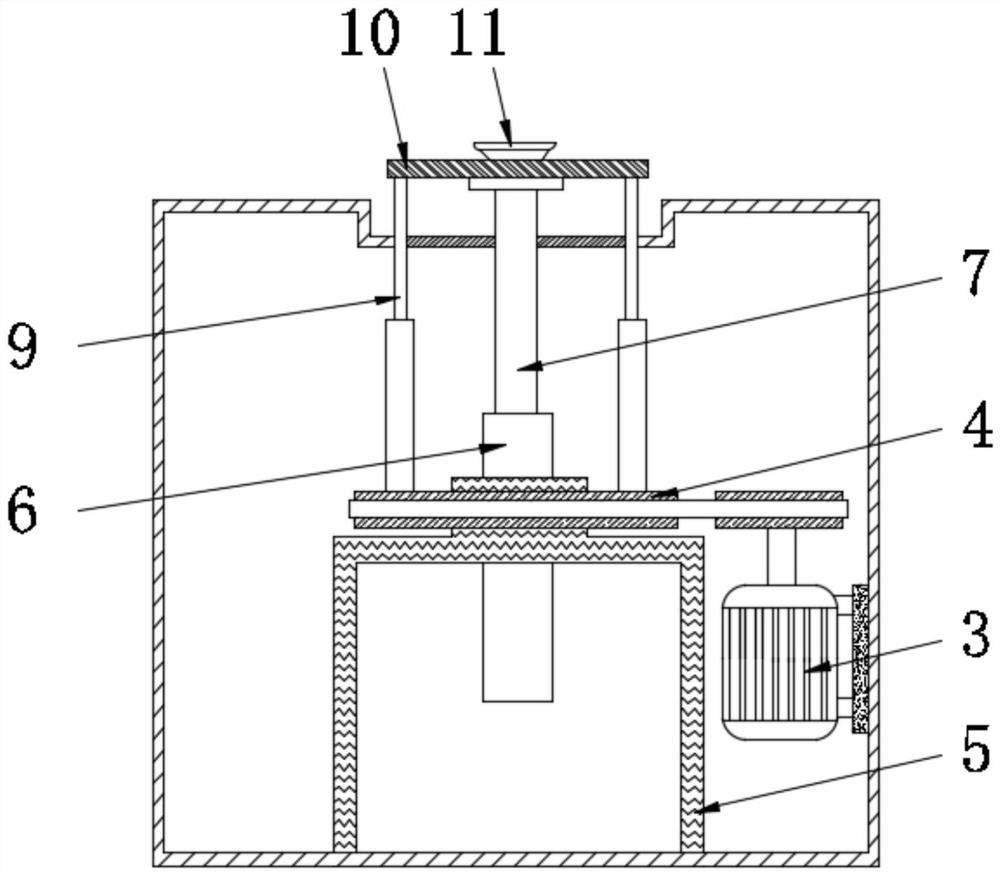

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] The invention provides an optical lens processing device, such as the attached figure 1 To attach Figure 5 Shown: including machine base 1, workbench 2 is fixedly installed on the upper surface of machine base 1, and drive motor 3 is fixedly installed on the inner wall of machine base 1, and the output end of drive motor 3 is fixedly connected with pulley 4, and pulley 4 is installed in rotation Outside the bearing seat 5, a sleeve 6 runs through the inner center of the bearing seat 5. A support rod 7 is slidably installed inside the sleeve 6. A coil 602 is arranged at the bottom end of the support rod 7. Below the coil 602 and on the sleeve Corresponding coils 602 are arranged inside the tube 6, and the connection between the support rod 7 and the sleeve 6 is fixedly installed with a limit block 8 on the inner wall of the sleeve 6, and a telescopic rod 9 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com