All-solid-state three-layer electrolyte and preparation method of all-solid-state battery

An electrolyte, all-solid-state technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, solid electrolytes, etc., can solve the problems of reducing the mechanical properties of electrolytes, increasing the interface impedance, affecting lithium ion transmission, etc., to improve the capacity and rate performance, The effect of increasing effective contact area and increasing reactive sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

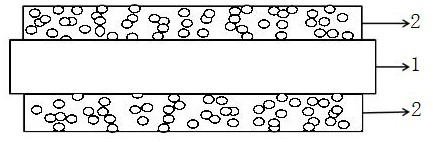

[0041] In order to solve the problem of poor interface compatibility between the electrolyte and the electrode of the existing all-solid-state lithium battery, which affects the transmission of lithium ions, this embodiment discloses a porous / dense / porous three-layer electrolyte and an all-solid-state lithium battery based on it. Solid-state lithium battery, the specific preparation method is as follows:

[0042]The selected ceramic material is an inorganic fast ion conductor, specifically including: lithium phosphorus oxynitride-LIPON (Li 2.9 PO 3.3 N 0.46 ), sodium fast ion conductor-NASICON (LiM 2 (PO 4 ) 3 , M = Ti / Zr), garnet-garnet (Li 7 La 3 m 2 o 12 (M=Nb,Ta)), perovskite-perov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com