Graphite composite material coated with lithium titanium aluminum phosphate, preparation method of graphite composite material and battery negative electrode

A lithium titanium aluminum phosphate and composite material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of low lithium ion transmission rate and achieve good lithium ion transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

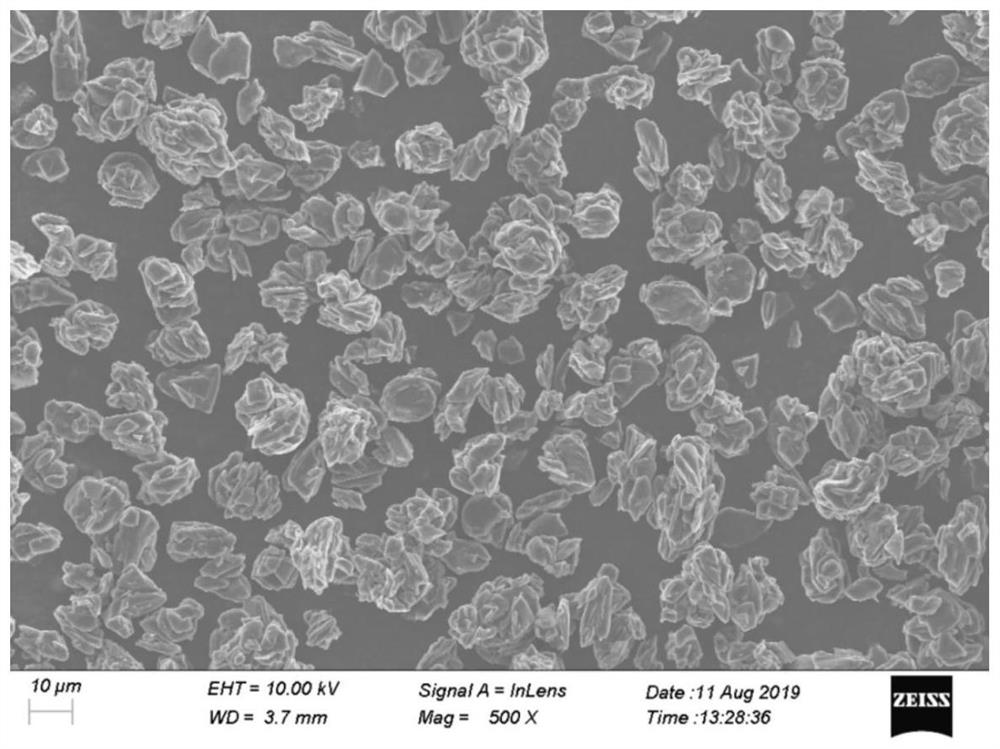

Image

Examples

preparation example Construction

[0036] The present application also provides a preparation method of the graphite composite material coated with lithium titanium aluminum phosphate, including:

[0037] Mix lithium titanium aluminum phosphate, oxidant, organic solvent, polymer and graphite, dry and remove the organic solvent, and then carbonize to obtain the precursor;

[0038] The precursor is mixed with the passivation solution, the precursor is passivated, and then dried to obtain the graphite composite material coated with lithium titanium aluminum phosphate.

[0039] Exemplarily, the polymer is selected from at least one of polyvinylidene fluoride, polyethylene oxide, polyethylene, polystyrene, polyvinyl chloride, polyether, polyester, polyamide and polyurethane.

[0040] The organic solvent can be selected from carbon tetrachloride, N-methylpyrrolidone, tetrahydrofuran and the like. The organic solvent does not react with the polymer, and the organic solvent is volatile during the drying process.

[0...

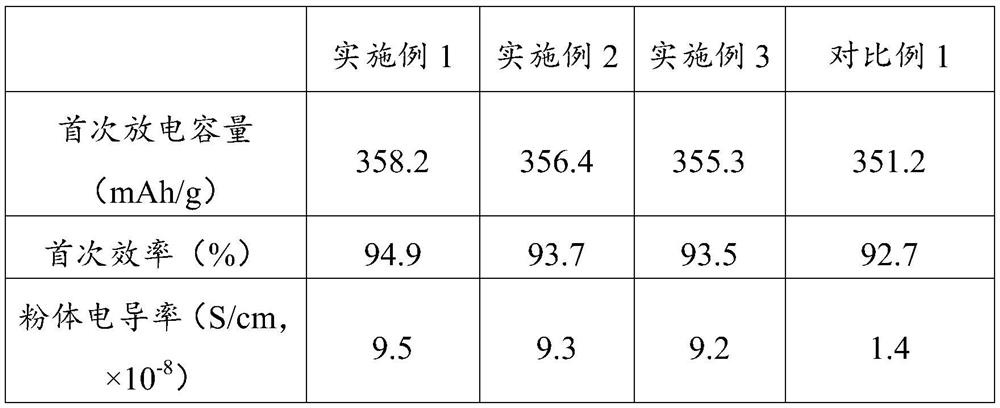

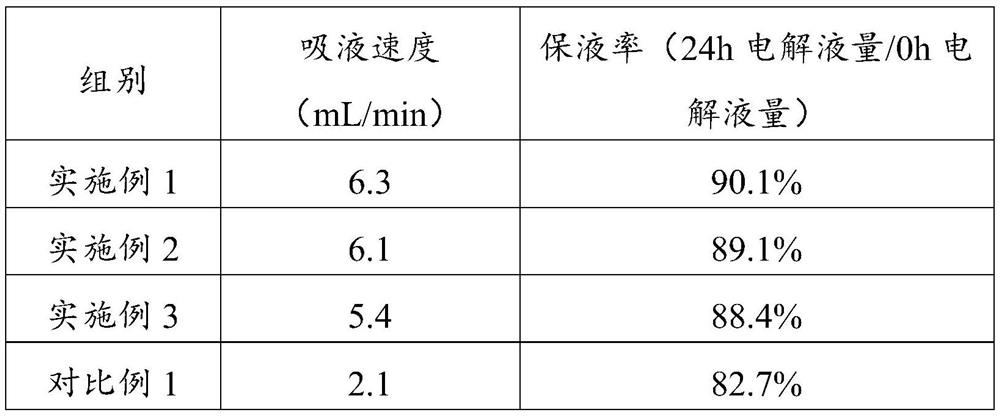

Embodiment 1

[0057] This embodiment provides a graphite composite material coated with lithium titanium aluminum phosphate and a negative electrode, which are mainly prepared by the following method:

[0058] Dissolve 3g of polyvinylidene fluoride in 800g of carbon tetrachloride, add 60g of lithium titanium aluminum phosphate, 6ml of 50wt% ferric methanol p-toluenesulfonate as an oxidant, and configure a precursor mixture with a concentration of 7.5wt%;

[0059] Take 100g of the precursor mixture, add 200g of artificial graphite, disperse it evenly through a ball mill, and then spray dry it. Then, under an argon inert atmosphere, heat up to 800°C at a rate of 5°C / min for carbonization for 48 hours, and then cool down naturally to At room temperature, pulverize to obtain the precursor material.

[0060] Put 10g of precursor material into 100ml ethanol solution passivation solution with a concentration of 5wt% iodine element, and conduct surface passivation at 60°C for 6h, then wash with dei...

Embodiment 2

[0066] This embodiment provides a graphite composite material coated with lithium titanium aluminum phosphate and a negative electrode. The graphite composite material coated with lithium titanium aluminum phosphate is mainly prepared by the following method:

[0067] After dissolving 1g of polyethylene oxide in 520ml of N-methylpyrrolidone, 50g of lithium titanium aluminum phosphate and 33ml of 30wt% ferric methanol p-toluenesulfonate were added as an oxidant to form a precursor mixture with a concentration of 10wt%.

[0068] Take 100ml of the precursor mixture, add 100g of artificial graphite, disperse evenly through a ball mill, and then spray dry it. Then, under an argon inert atmosphere, heat up to 700°C at a rate of 1°C / min for carbonization for 72 hours, and then cool down naturally to At room temperature, pulverize to obtain the precursor material;

[0069] Put 10g of precursor material into 100ml ethanol solution passivation solution with a concentration of 1wt% iodin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com